32

5. Safety Equipment

Do not operate the loader unless equipment shields, seat

belt, seat bar, hydraulic controls, parking brake, operator

guard and lift arm supports are working properly as well as

all safety and instruction decals are in place.

6. Decals

Check the condition of all safety and instruction decals.

Replace any damaged or missing decals. Refer to section

5. 4 for decal description and locations.

7. Lubrication

There are sixteen grease fittings located in the loader that

require lubrication every eight hours. Lubricate with a

good quality multi-purpose lithium based grease. Apply

grease until excess shows. Refer to the service schedule for

complete service details.(See Fig. 4. 4G). The sixteen

lubrication points are:

Rear Lift Arm Pivots (2)

Lift Arm Cylinder Bushings (4)

Bucket Cylinder Bushings (4)

Lift Arm Supports (2)

Quick Tach Pivot and Lock Pins (4)

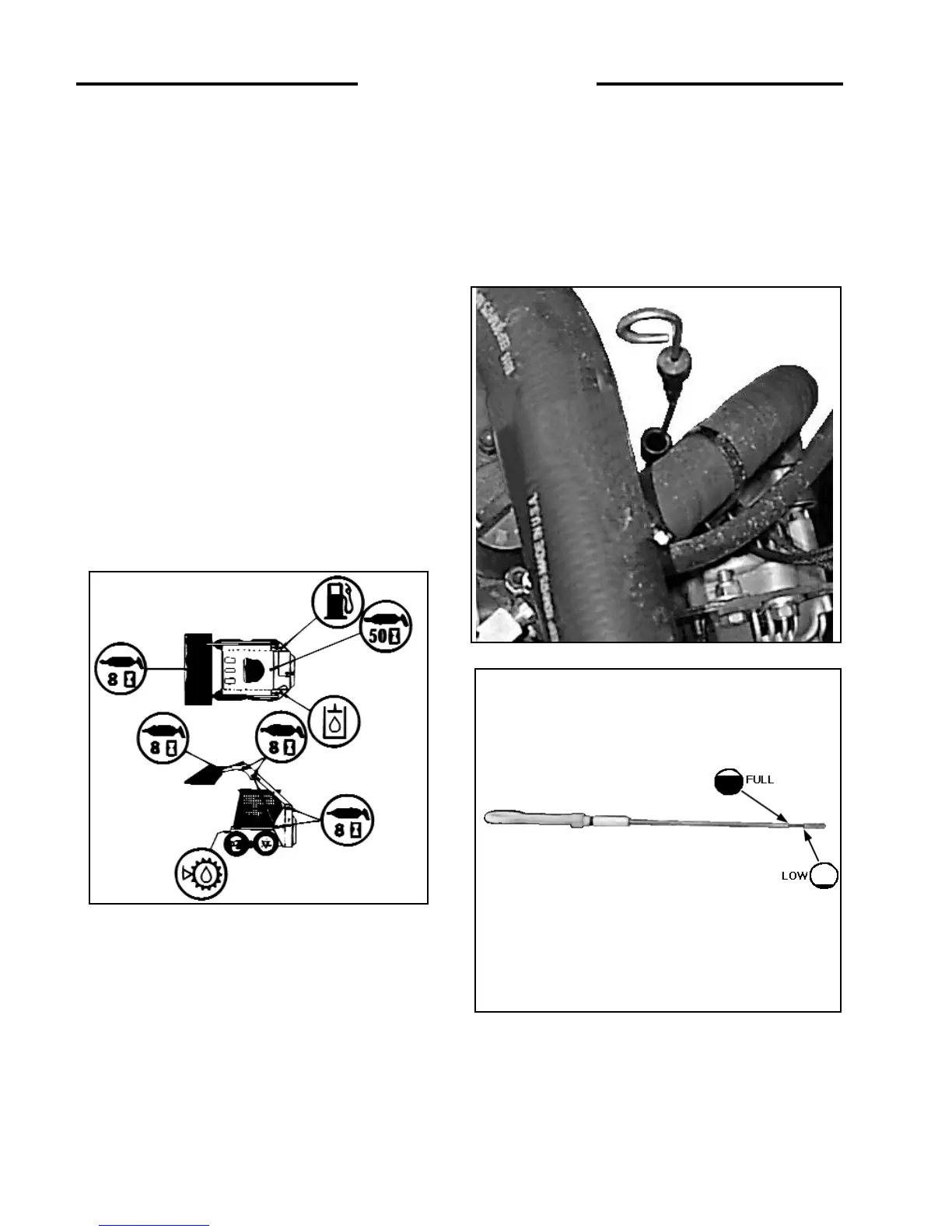

8. Engine Oil Level

To check the oil level, stop the engine with the loader on

level ground, open the rear door and remove the dipstick

(Fig. 4. 4I1).

Keep the oil level between the full and low mark on the

dipstick (Fig. 4. 4I2). Do not fill above the full mark (See

Section 5 for appropriate oil).

4...MAINTENANCE

C - 642

fig. 4. 4I2

FIG 4. 4I1

C-880

C-732

Fig. 4. 4G

Loading...

Loading...