48

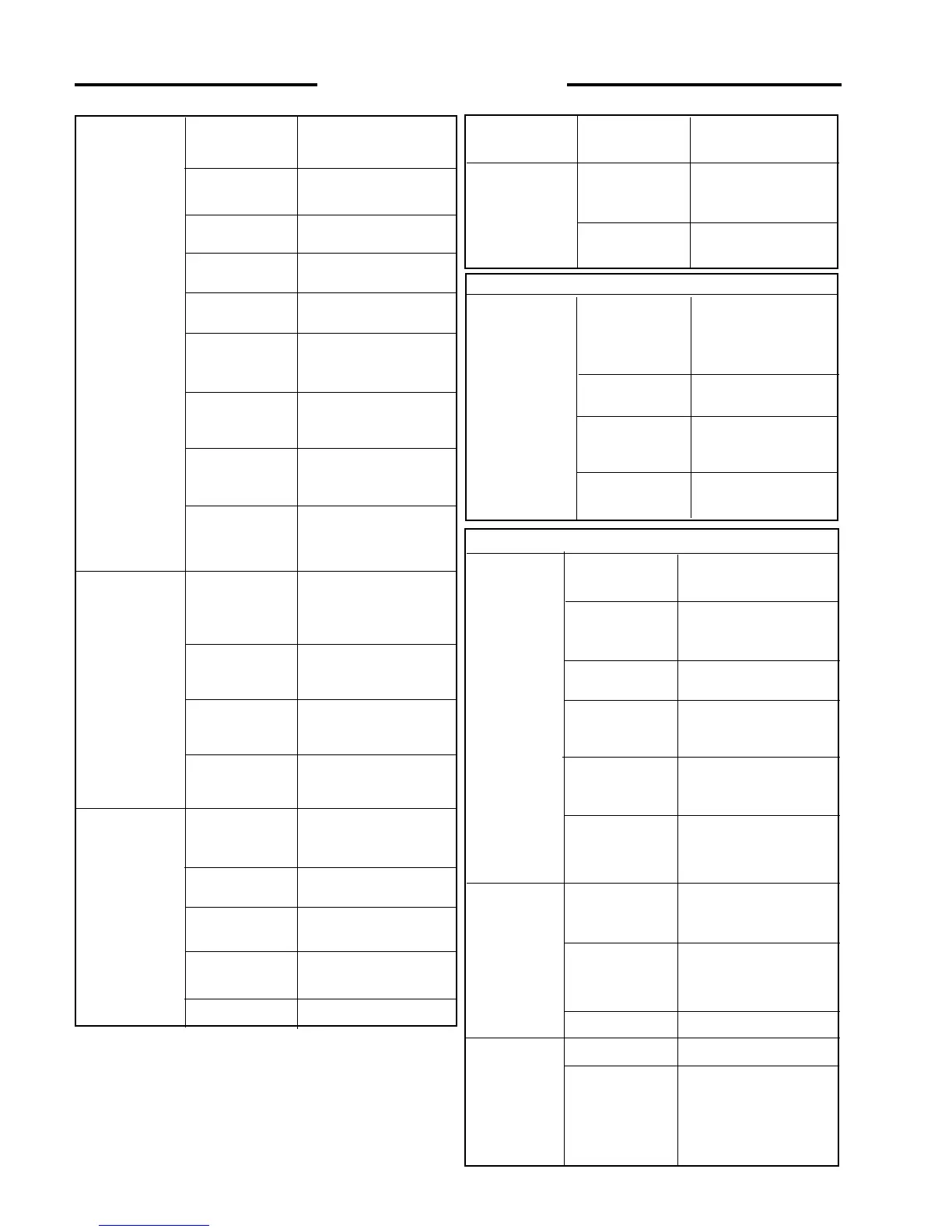

Control levers

will not centre

Machine operates

erratically

Machine will not

travel in straight

line

Linkage out of

adjustment

Linkage

disconnected

Centering spring

broken

Linkage binding

Control lever

linkage loose

Spiral pin in pintle

lever worn or

broken

Linkage binding

Control lever

travel out of

adjustment

Adjust, check for wear at

rod ends, loose counter

nuts

Reconnect, check for wear

at rod ends, loose counter

nuts

Replace

Binding of spring bushing

in spring box. Align spring

box with linkage.

Control levers binding

with safety shields or

sound insulation Adjust

Control lever bearings

binding in lever assy.

Inspect replace or clean as

required

Inspect linkage for wear at

rod ends, loose counter

nuts

Replace pin. Inspect pintle

lever for wear at pin hole.

Ensure bolt clamping lever

to pump shaft is tight

See hydrostatic system

Adjust

Adjust

Final drive

transmission

noisy

No lubricating oil

Axles have too

much end play

Chain loose

Check and bring oil to

the proper level. Use

appropriate engine oil

(See Section 5 for

specifications).

Pre-load axle bearings

removing all end play

Replace the chain

3. Final Drive Transmission

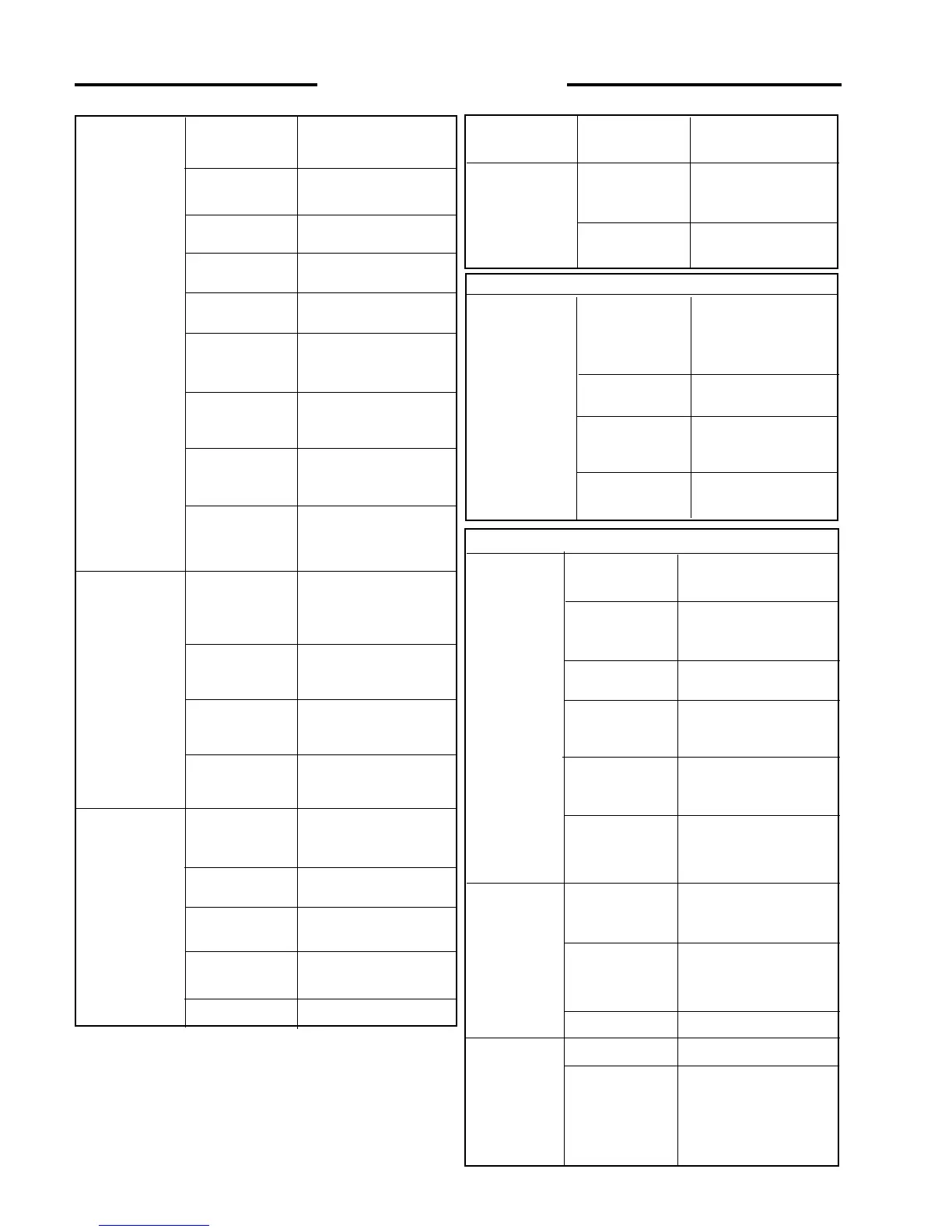

Foot pedals do

not operate

smoothly

Foot pedal linkage

out of adjustment

Foot pedal

linkages need

lubrication

Cable Binding

Adjust foot pedal

linkages

Lubricate with a

silicone based lubricant

Check routing for kinks

etc.

Lift arms raise

slowly at full

engine rpm

Lift or tilt

cylinders will not

support a load

Hydraulic oil

overheating

Anti-cavitation

check valve not

functioning

Reservoir low on

oil

Foot pedal linkage

binding

Auxiliary foot

pedal engaged

Engine RPM too

slow

Anti-cavitation

check valve spring

broken

Main relief valve

in control valve

faulty

Internal leakage in

pump due to wear

Oil bypassing one

or both lift

cylinder piston

seals

External leak

between or at

control valve and

cylinders

Control valve

spool not

centering

Oil leaking by one

or both cylinder

piston seals

Reservoir low on

fluid

Auxiliary foot

pedal engaged

Engine RPM too

slow

Incorrect

temperature

sensor

Inspect and repair or

replace

Replenish with appropriate

oil (See Section 5 for

specifications).

Inspect and adjust

Disengage

Check RPM and reset

Replace

Check pressure if

necessary - adjust

Check pump flow and

repair or replace as

necessary

Install new piston seal kits

Check for leaks and

correct

Check for sticking foot

pedal linkage

Check for broken or stuck

return spring on valve

spool

Install new piston seal kits

Replenish with appropriate

oil(See Section 5 for

specifications).

Disengage

Check RPM and adjust

Replace

4...MAINTENANCE

4. Control Levers

Loading...

Loading...