47

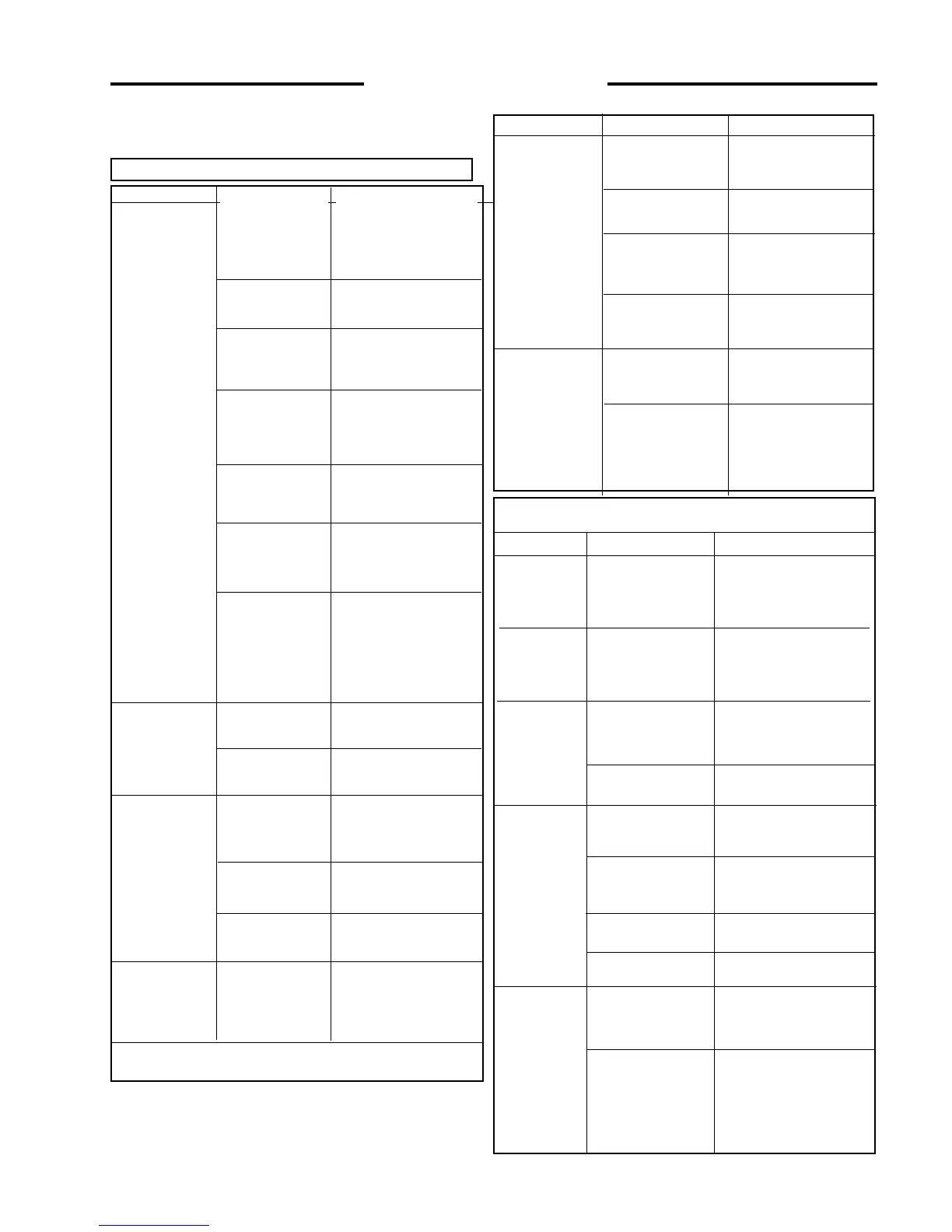

PROBLEM CAUSE REMEDY

Loss of

hydraulic

power (no

flow from

gear pump)

Loss of

hydraulic

power (flow

from gear

pump)

Hydraulic

action jerky

Reservoir low on

fluid hose or fitting

leak.

Flexible coupling

between engine and

pump failure

Spline coupling

failure between front

and rear hydrostatic

pump

Hydraulic gear pump

not functioning

Reservoir low on

fluid

Foot pedal linkage

disconnected or

binding

Auxiliary foot

pedal engaged

Relief valve failure in

control valve

Reservoir low on oil

Air in hydraulic

system

Replenish with

appropriate oil (See

Section 5 for

specifications). Check for

leaks.

Inspect and replace

damaged parts. Check for

misalignment between

engine and

pumps.

Inspect coupling for

sheared splines. Also

check pump shaft

bearings.

Inspect and repair.

Replenish with

appropriate oil (See

Section 5 for

specifications).

Inspect and adjust.

Disengage

Check pressure and

adjust.

Replenish with

appropriate oil (See

Section 5 for

specifications).

Check for leak

between reservoir

and pump. Bleed System

by extending and

retracting lift cylinders

several times.

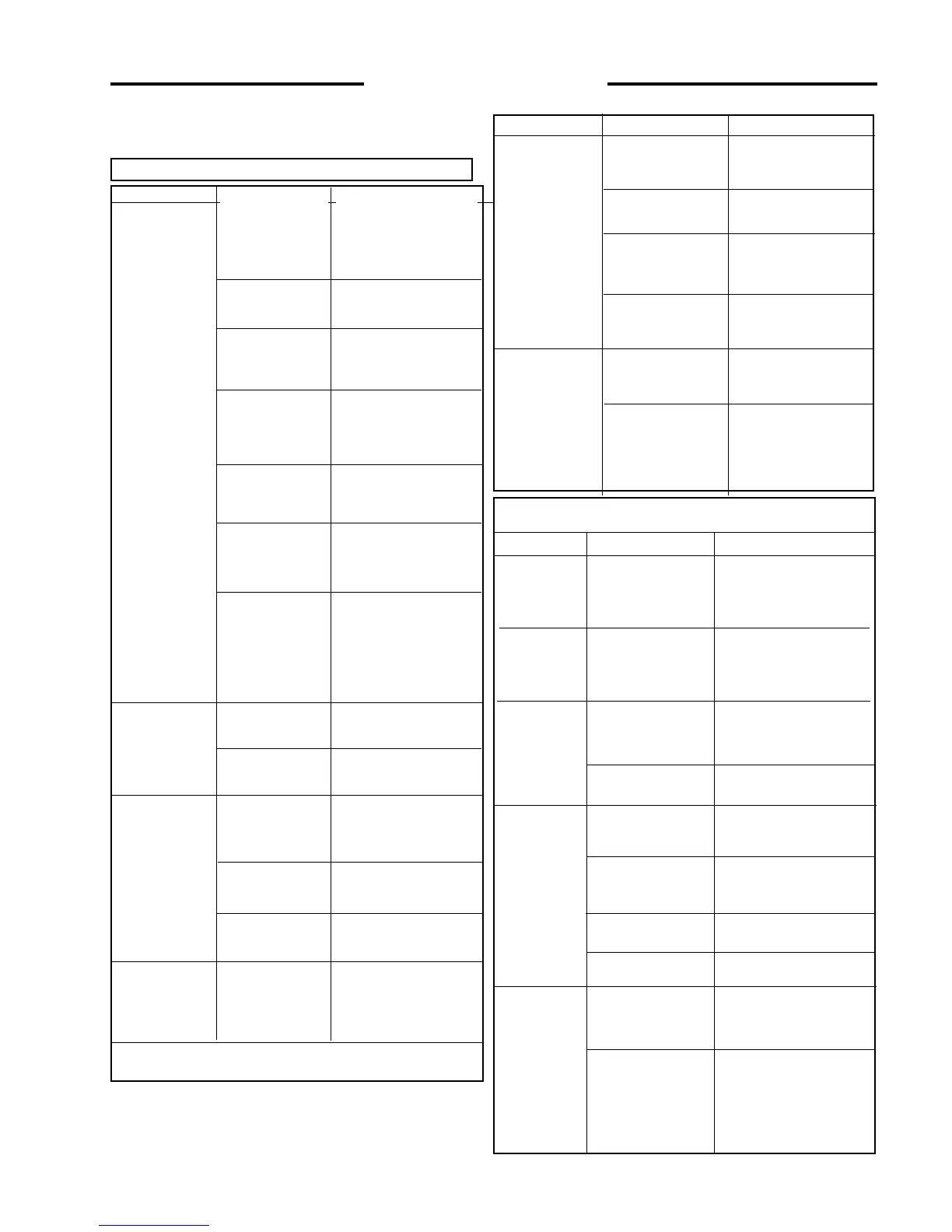

Power Cause Remedy

4...MAINTENANCE

1. Hydrostatic Drive

4. 11 TROUBLESHOOTING

2. Hydraulic System

Power

No power on

one side (both

directions)

No power on

one side (one

direction only)

No power on

both sides, also

loss of hyd.

power

Gradule loss of

power as

machine warms

up

Cause

Reservoir low on

oil

Disconnected

control linkage

Groove pin

sheared on pump

pintle lever

High pressure line

failure

Drive chain

failure.

Adjust tightener

tension.

Motor shaft or key

failure. Check

mounting bolts.

Excessive internal

leakage in motor

and/or pump.

Defective relief

valve

Damaged ball

check

Reserve low on

oil.

Pump coupling

failure

Check system

pressure

Excessive internal

leakage in pump

and/or motor.

Remedy

Replenish with

appropriate oil (See

Section 5 for

specifications). Check

for hose or fitting leak.

Reconnect and adjust

linkage.

Replace. Check pintle

lever for loose bolt or

excessive play.

Replace line. Ensure

new line fits without

being forced. If

necessary, stress relieve.

Replace chain or

connection link.

Inspect and repair

defective parts.

Inspect and repair

defective unit. Flush all

lines and tank. Replace

filter. Check on type of

fluid used and engine

RPM.

Replace defective valve.

Disassemble and repair.

Replace with appropriate

oil (See Section 5 for oil

specifications).

If damaged, consult

dealer or Thomas

Service Dept.

If low, consult dealer or

Thomas Service Dept.

Consult dealer or

Thomas Service Dept.

System erratic

and/or noisy

Machine will not

travel in a

straight line in

high range

Air in system due to

low oil level in

reservoir

Air in system due to

leak at suction fitting

Internal pump or

motor wear caused

by overspeeding

Excessive play in

linkage or pintle

lever

Control levers

binding

Replenish using

appropriate oil (See

Section 5 for

specifications)

Check fittings and

tighten.

Consult your dealer or

Thomas Service Dept.

Adjust linkage and

tighten or replace pintle

lever.

Check that shields are

not stopping lever from

full travel.

Check for linkage

binding at spring mount.

Adjust tracking.

Loading...

Loading...