24

Description

Product

TK Elevator

BA, TW45 | 6231003860 | 03/2023

3.3.3 Special versions

The following optional versions are possible:

▪ Emergency brake, NBS (only with machine location in the machine room

or ISIS1)

▪ Actual-value sensor in accordance with

Chap.4.1.3P.29

▪ Earthquake safeguard complying with EN81-77 (only with machine loca-

tion in the

machine room; not with horizontal rope departure direction)

▪ SA1 - modified machine fastening (including compensating sheaves) for

horizontal or vertical upward force resulting from rope pull

▪ Horizontal rope departure direction; other information Product

▪ Version for ISIS1 (description Product)

Other special versions or options are currently not available.

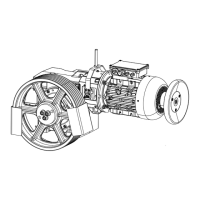

3.3.4 Standard version for machine in the machine room

The standard version of the machine TW45C comprises the following com-

ponents:

▪ Driving gear (incl. oil filling; vertical/horizontal motor position; traction

sheave position - left/right)

▪ Gear ratios 46:1, 32:1, 41:2, 40:3 or 32:3 (32:3 only for ISIS1)

▪ Service brake type Mayr RSZ125-2x50 Nm including permanently moun-

ted brake release lever and brake monitoring (microswitch)

▪ Motor in version EME (CEG) MT132 (5.2 kW) or EME (CEG) MT132 (7

kW); mounting with terminal box location Product and as standard; motor

versions with intermediate terminal connection for connection lines of the

service brake

▪ Encoder; version WDG100-1024 TTL as standard

▪ Handwinding wheel, diameter 270

▪ Traction sheave dia. 440, dia. 520 or dia. 590 as standard

▪ Components for the rope guard; standardised for traction sheave dia. ,

440, 520 and dia. 590

▪ Blocking clamp

3.3.5 Version with emergency brake, NBS

The optional version of the emergency brake (NBS) meets the requirements

for the protection device that prevents overspeed in the upward-moving elev-

ator car in accordance with EN81-1:1998 / 9.10 and/or EN81-20/5.6.6 and un-

intended elevator car movements in accordance with EN81-1:2010-06 / 9.11

(EN81-1/A3) and/or EN81-20/5.6.7.

In the ISIS1 version, the NBS emergency brake also meets the requirements in

accordance with ASME A17.1.

Alongside the service brake, an additional braking device is fitted on the drive

shaft, consisting of the components:

▪ Type-approved electromagnetic disc brake in accordance with

Chap.4.1.6P.32

Loading...

Loading...