28

Technology

Mechanical data

TK Elevator

BA, TW45 | 6231003860 | 03/2023

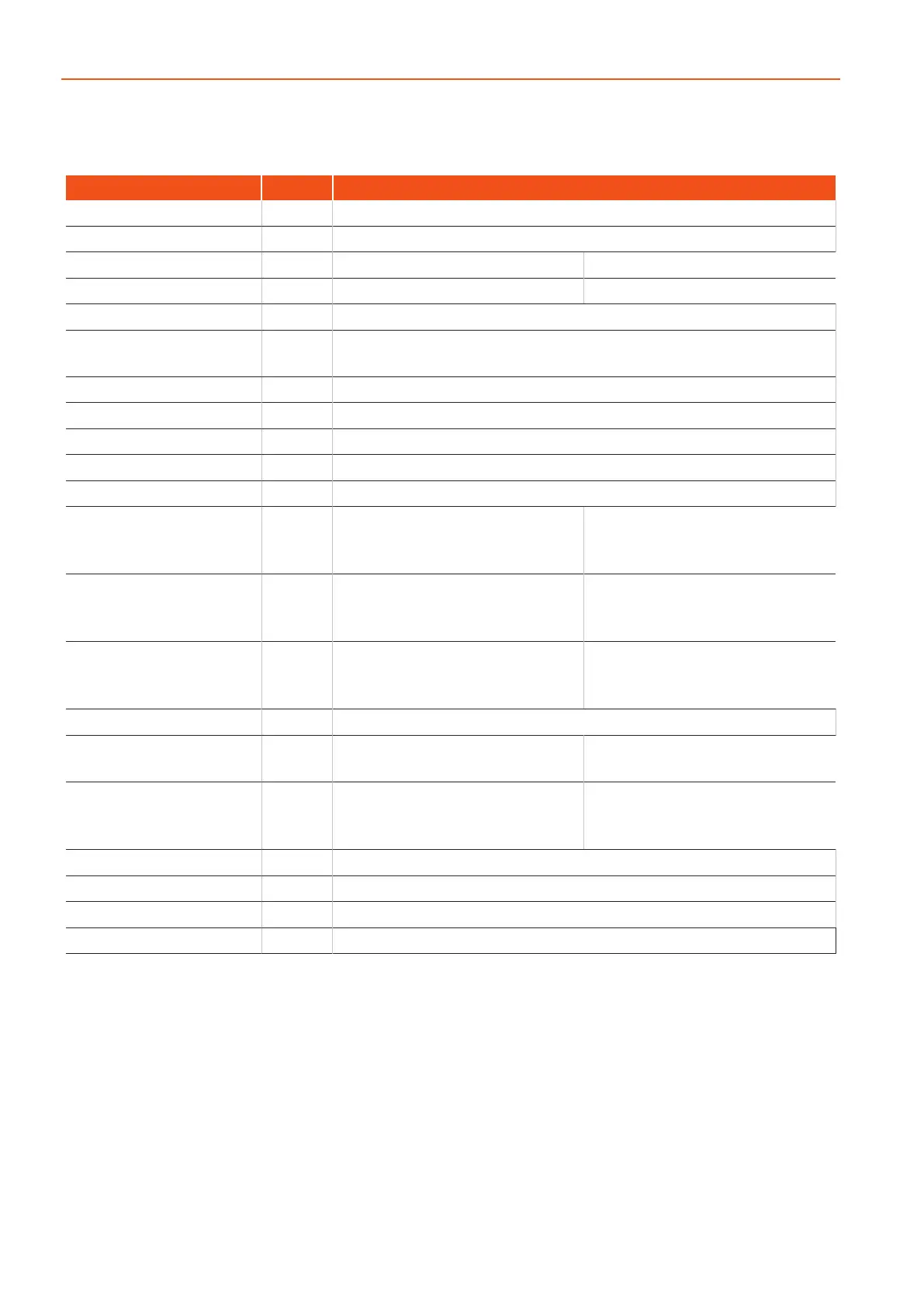

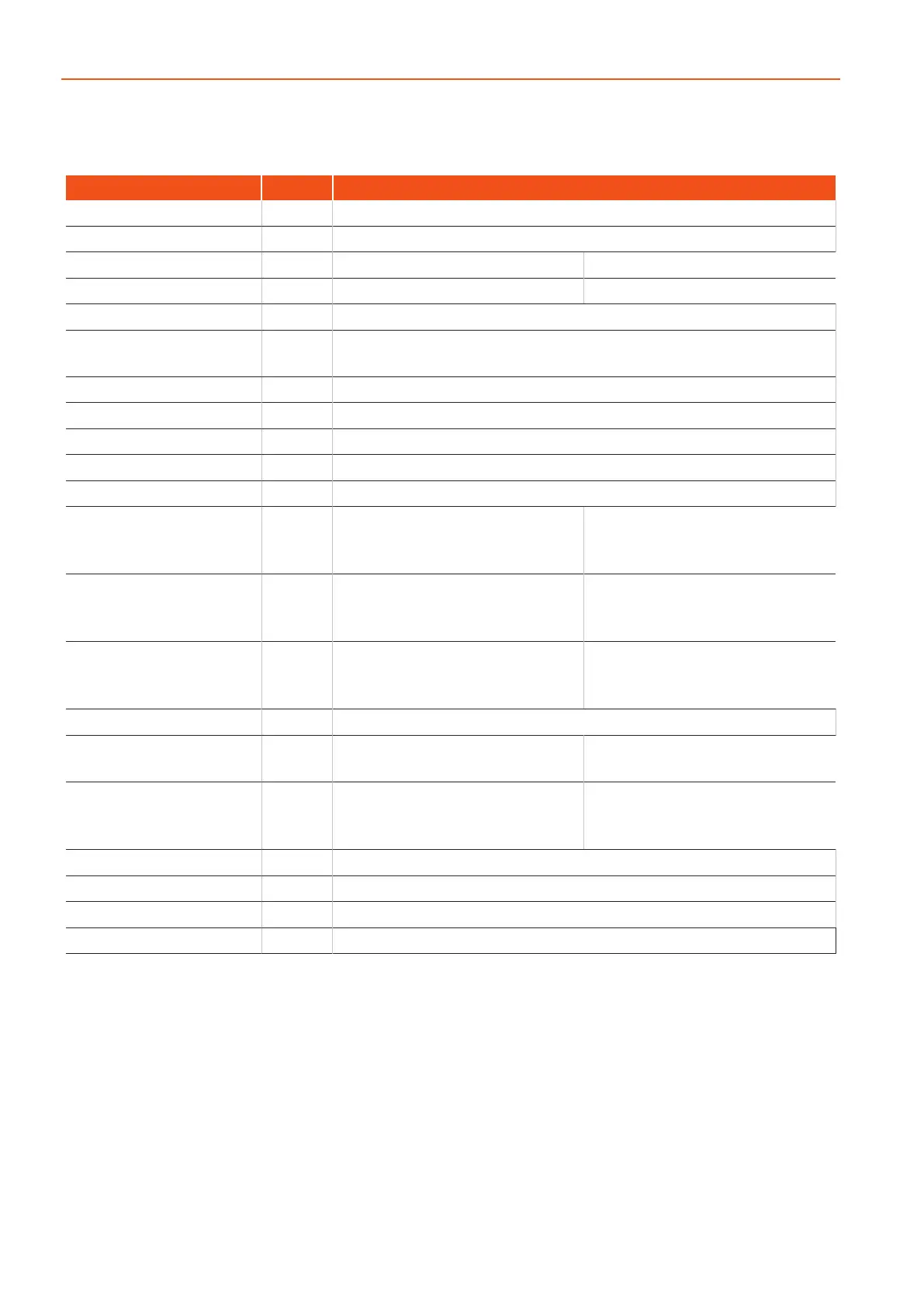

4.1.2 Brake

Version for deployment in the machine room and ISIS1 (MRL)

Designation Unit Technical data

Manufacturer Chr. Mayr GmbH

Type ROBA-stop RSZ125

Version Machine room ISIS1 (MRL)

Braking torque [Nm] 2 x 50 100 (2 x 50)

Braking torque setting Not possible

Design

2-surface disc brake (2 mechanical brake circuits with a joint electro-

magnetic circuit for release)

Brake linings Asbestos-free

Brake disc diameter [mm] 130

Air gap [mm] 0.5 +0.25

Air gap setting Not possible

Electrical release 1 magnetic clamp with armature base plate

Operating voltage

Overexitation / holding

current

[VDC] 180 / 90 110 / 55

Operating current

Overexitation / holding

current

[A] 1.68 / 0.84 2.58 / 1.29

Performance data

Overexitation / holding

current

[W] 303 / 76 284 / 71

Monitoring devices Release monitoring (microswitch)

Manual release

Manual release lever (permanently

mounted)

1)

without

Connection lines, coil and

microswitch

[m]

1 m (with end sleeves; connection

lines have intermediate clamping

in the motor terminal box)

3 m (with end sleeves; connection

lines are routed through the motor

terminal box)

Type of protection IP54

Weight [kg] approx. 11

CSA LR 34805

Type approval code without (not required)

Tab.3 ATR_1_21_0023_0

1)

Manual release of both brake circuits; single-circuit test by means of pluggable test gauges.

In general, this brake is made with brake monitoring (microswitch).

This brake is also used for the ISIS1 version with the machine in the shaft pit,

but in an adapted version with altered voltage and without a manual release

lever. With ASME A17.1, the brake is regarded as 100 Nm (2x50 Nm).

Loading...

Loading...