3-57

Chapter 3

INSTALLATION AND SETTING PROCEDURES (HARDWARE)

8. CONNECTIONS

8.1. Removable Terminal Plug Connection

Notes

• Do not use a micro screwdriver. Sufcient torque is not given to the screws when tightening them, and

connections may not be secured.

• Avoid soldering stranded or shielded cable, as contact resistance may increase when the cable is tightened

and the solder is crushed, possibly resulting in an excessive rise in joint temperatures.

• When connecting 2 cables or a shielded cable to a single terminal, use a ferrule terminal with an insulation

sleeve to crimp the cables because such cable conductors could become loose.

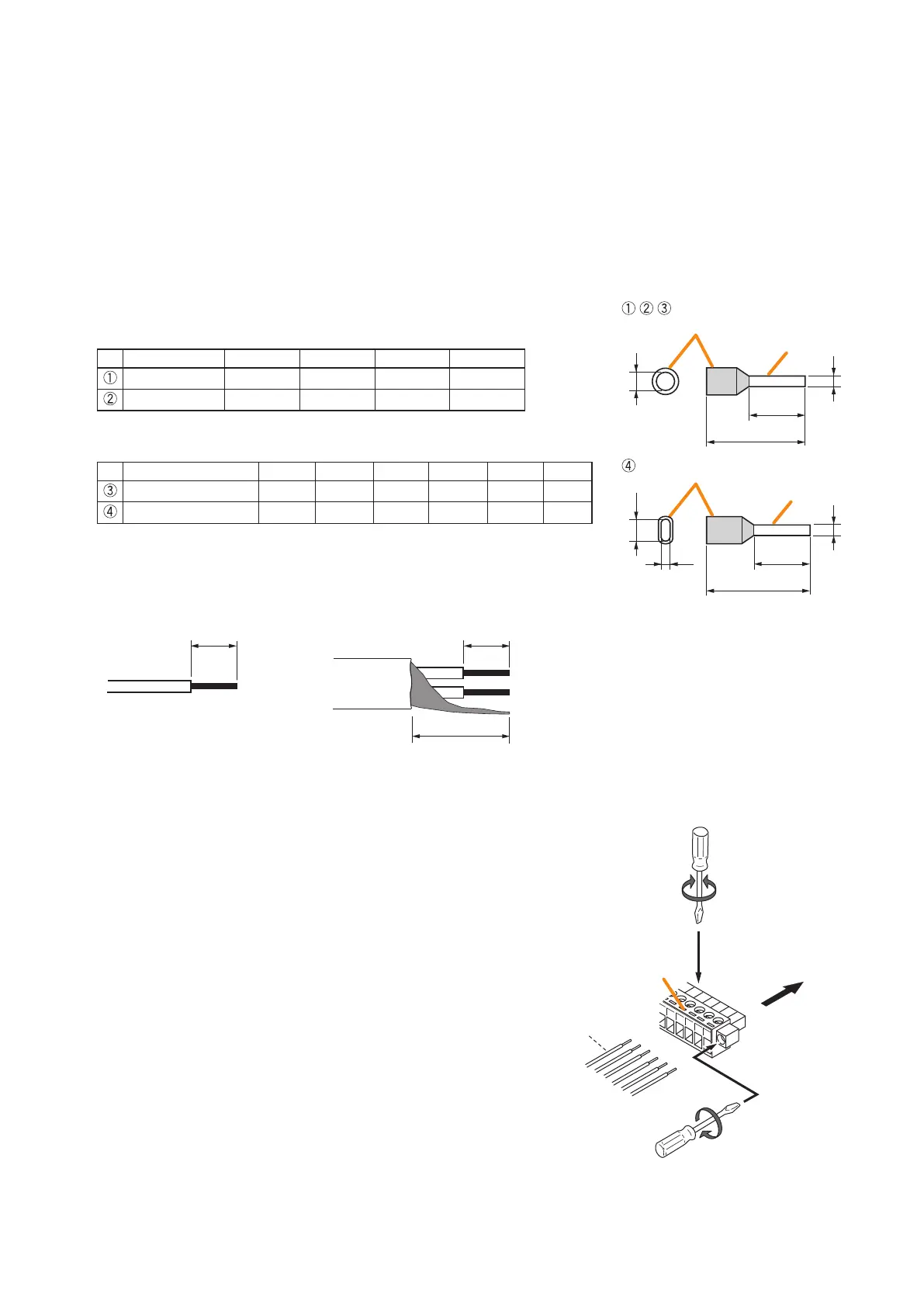

Recommended ferrule terminals for signal cables

(made by DINKLE ENTERPRISE)

Unit: mm

Model Number a b l1 l2

DN00308D 1.9 0.8 12 8

DN00508D 2.6 1 14 8

Recommended ferrule terminals for power supply cables

(made by DINKLE ENTERPRISE)

Unit: mm

Model Number a a1 a2 b l1 l2

DN01508D

3.5

- -

1.7 14 8

DN01508B

-

6.6 3.6 2.3 16 8

Crimping tool: DNT01-2206B (made by DINKLE ENTERPRISE)

[Cable sheath to trim]

Insulation sleeve

Contact section

Insulation sleeve

Contact section

a

l

2

a

1

a

2

l

1

l

2

l

1

bb

Solid cable and stranded cable

Shielded cable

7 mm*

7 mm*

15 mm

* Expose 8 mm or more when using the

above ferrule terminal, and cut off an extra

conductor protruding from the sleeve.

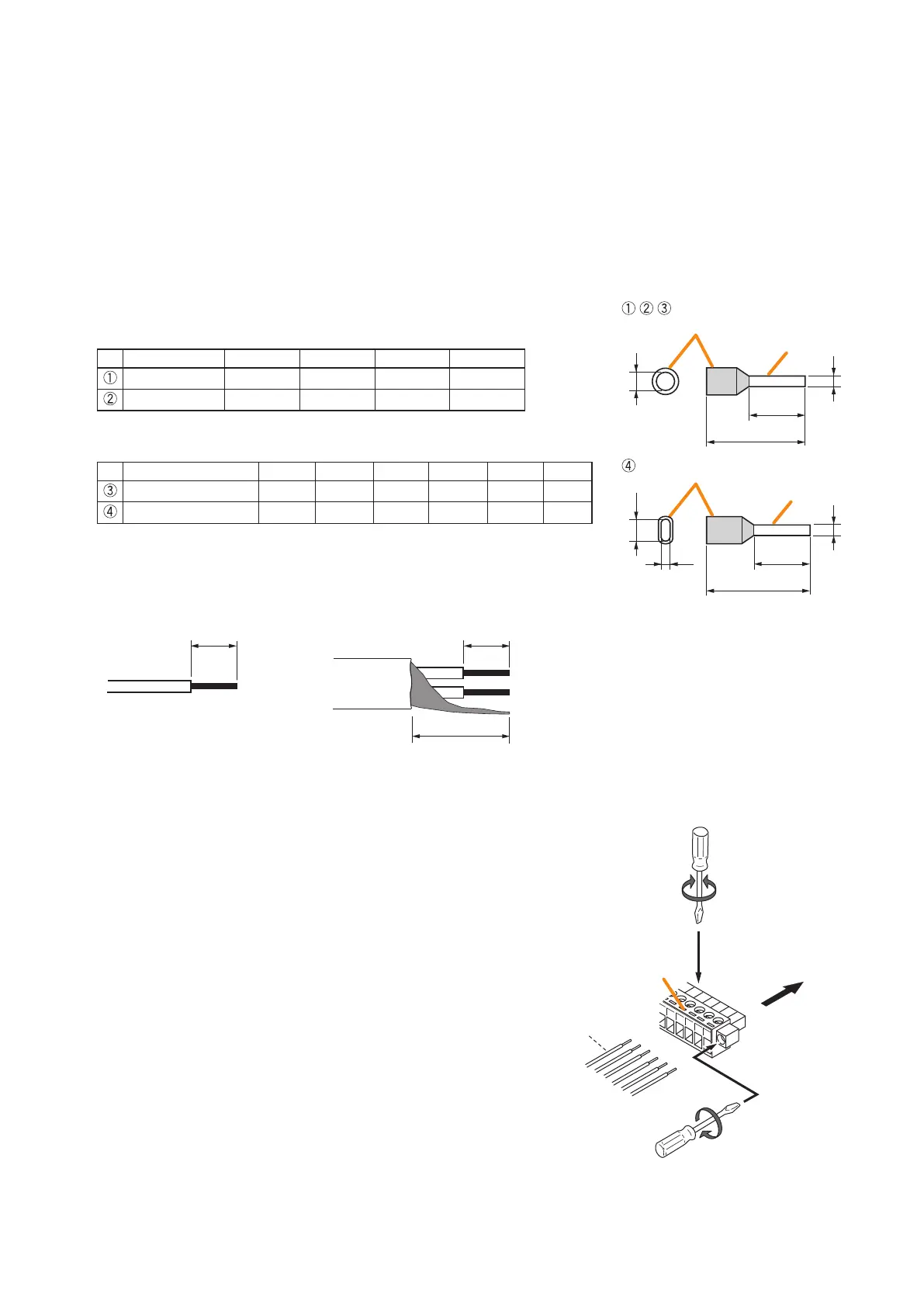

[Wiring procedures]

Procedures below are for the removable terminal plug with xing screws.

Step 1. Loosen the terminal screw and insert the

cable lead.

Step 2. Tighten the screw.

Pull on the cable lead to ensure it is securely

connected.

If the lead pulls out, loosen the screw and

follow the above procedures again.

Step 3. Insert the terminal plug into the corresponding

terminal block in the unit's rear panel.

Step 4. Tighten the xing screws.

Note

Do not reverse Steps 1 – 2 and 3 – 4 above. Force

is applied to the connected receptacle pins while

tightening the terminal screw and they may be

damaged, resulting in bad connector contact.

Removable

terminal plug

1

1

2

3

To Tighten To Loosen

Tighten

4

Loading...

Loading...