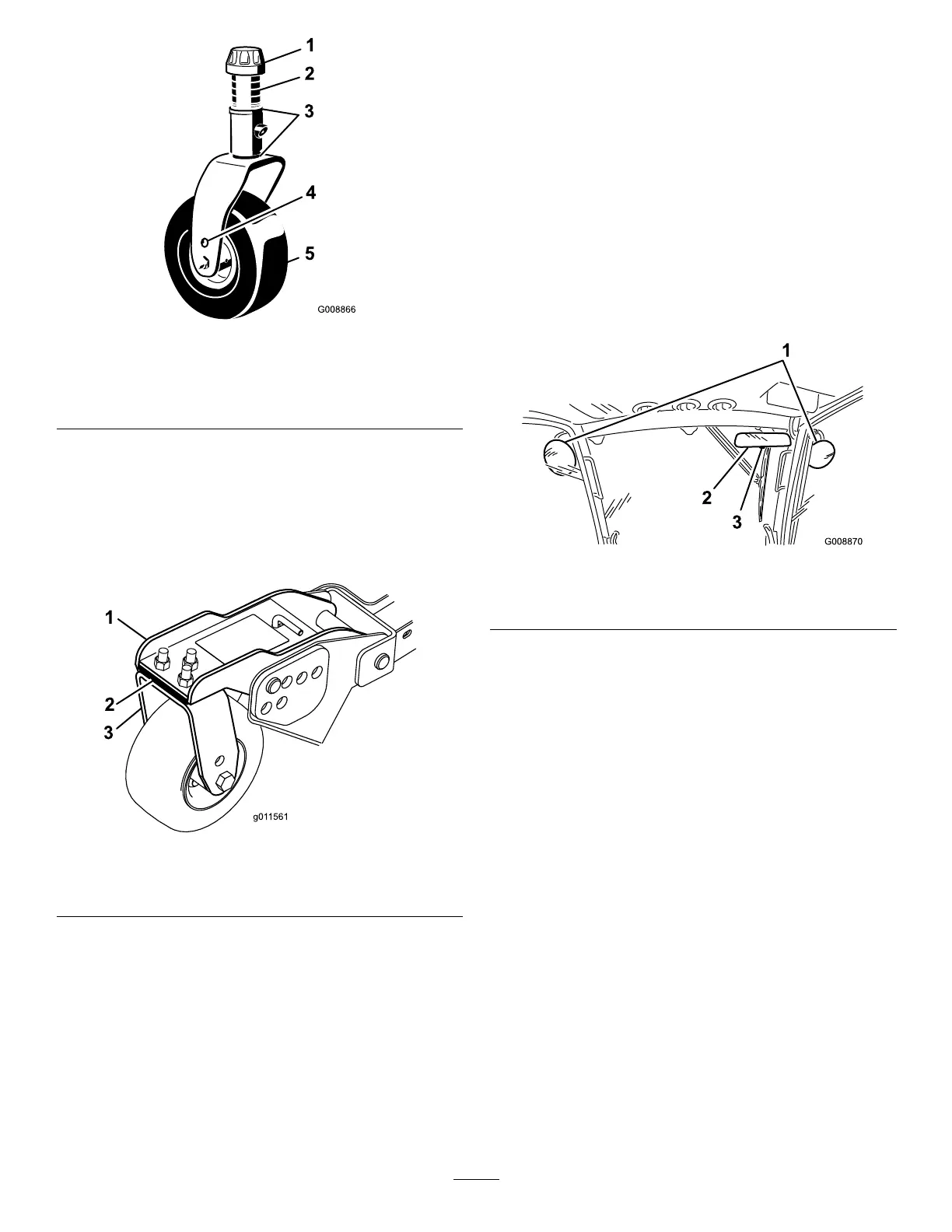

Figure28

1.T ensioningcap4.T opaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

WingCuttingUnitSetup

Rotatebladeofeachspindleuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipofthe

cuttingedge.Adjust1/8inchshimsonfrontcastorarm(s)

tomatchheightofcuttodecal(

Figure29).Fortheoutside

bladespindleonly,refertoAdjustingtheCuttingUnitPitch.

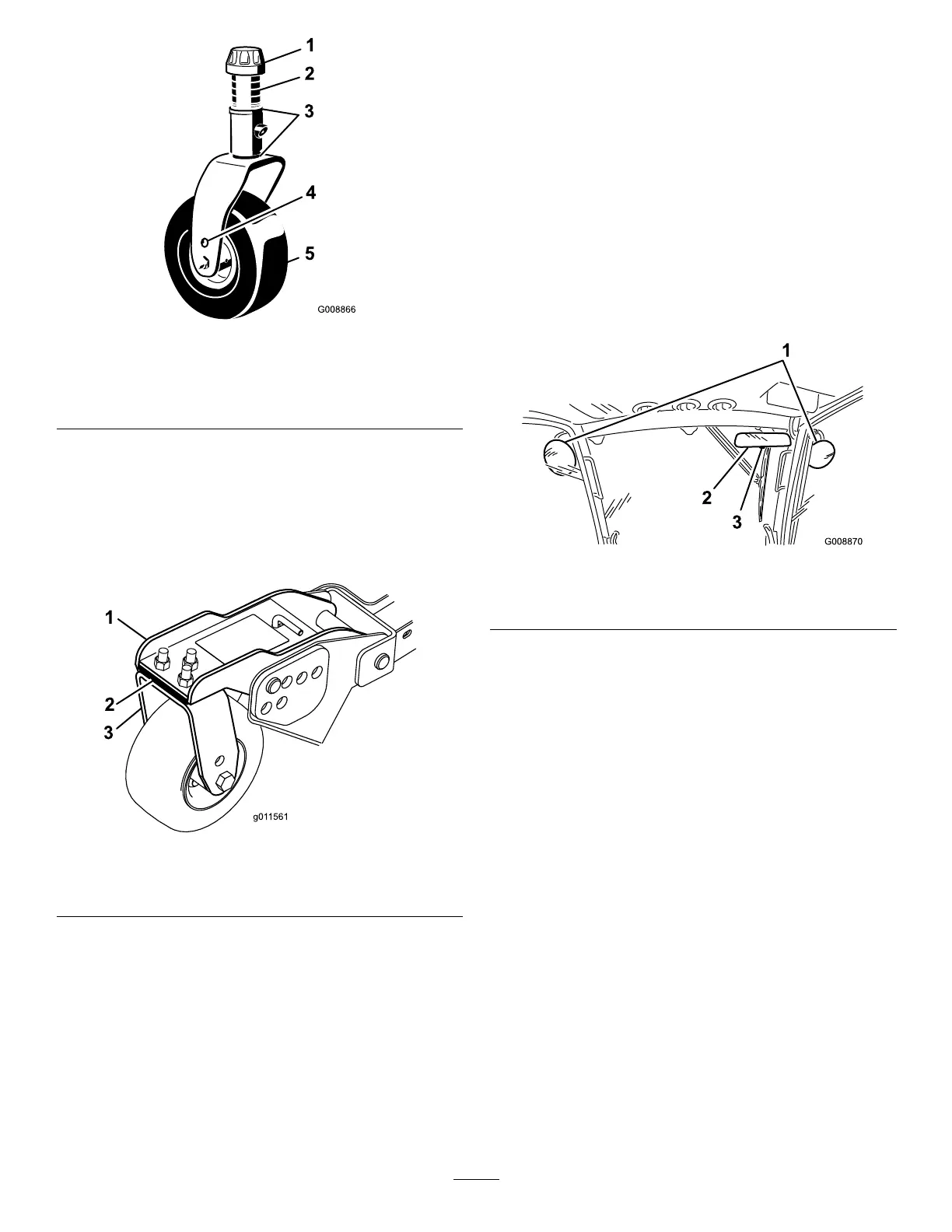

Figure29

1.Castorarm3.Castorfork

2.Shims

MatchingHeightOfCutBetweenCuttingUnits

1.Positionbladesidetosideonoutsidespindleofboth

wingcuttingunits.Measurefromtheoortothetip

ofthecuttingedgeonbothunitsandcompare.These

numbersshouldbewithin1/8inch(3mm)ofeach

other.

2.Addorremove1/8inchshimsasneededonwing

castorwheels.Recheckmeasurementbetweenoutside

edgesofbothwingcuttingunitsandadjustasnecessary.

AdjustingtheMirrors

Model30447only

RearViewMirror

Whilesittingintheseat,adjusttherearviewmirror

(Figure30)toattainthebestviewouttherearwindow.Pull

theleverrearwardtotiltthemirrortoreducethebrightness

andglareoflight.

SideViewMirrors

Whilesittingintheseat,haveahelperadjustthesideview

mirrors(Figure30)toattainthebestviewaroundthesideof

themachine.

Figure30

1.Sideviewmirrors

3.Lever

2.Rearviewmirror

AimingtheHeadlights

1.Loosenthemountingnutsandpositioneachheadlight

sothatitpointsstraightahead.Tightenthemounting

nutjustenoughtoholdtheheadlightinposition.

2.Placeaatpieceofsheetmetaloverthefaceofthe

headlight.

3.Mountamagneticprotractorontotheplate.While

holdingtheassemblyinplace,carefullytilttheheadlight

downward3degrees,thentightenthenut.

4.Repeattheprocedureontheotherheadlight.

StartingandStoppingthe

Engine

Important:Thefuelsystemwillautomaticallybleed

itselfwhenanyofthefollowingsituationsoccur:

•Initialstartupofanewmachine.

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuelsystem

components.

RefertotheBleedingAirfromtheInjectors.

26

Loading...

Loading...