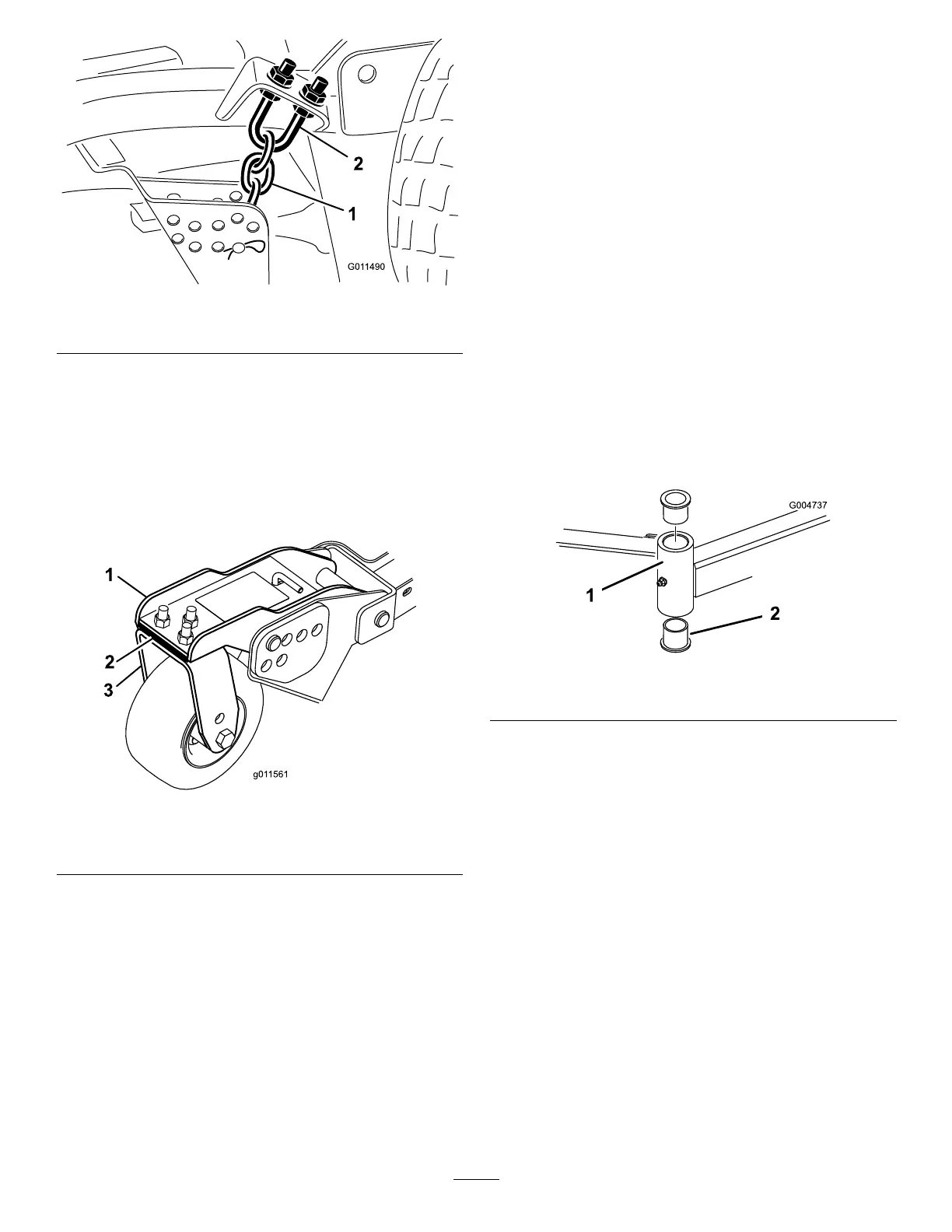

Figure79

1.Height-of-cutchain

2.U-bolt

AdjustingtheWingCuttingUnits

1.Removethecapscrewsandnutssecuringthecastor

armtothecastorfork(Figure80).

2.Repositiontheshims,asrequired,toraiseorlowerthe

castorwheeluntilthecuttingunithasthecorrectpitch.

3.Installthecapscrewsandnuts.

Figure80

1.Castorarm3.Castorfork

2.Shims

ServicingtheCastorArm

Bushings

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(

Figure81).Alsodrivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

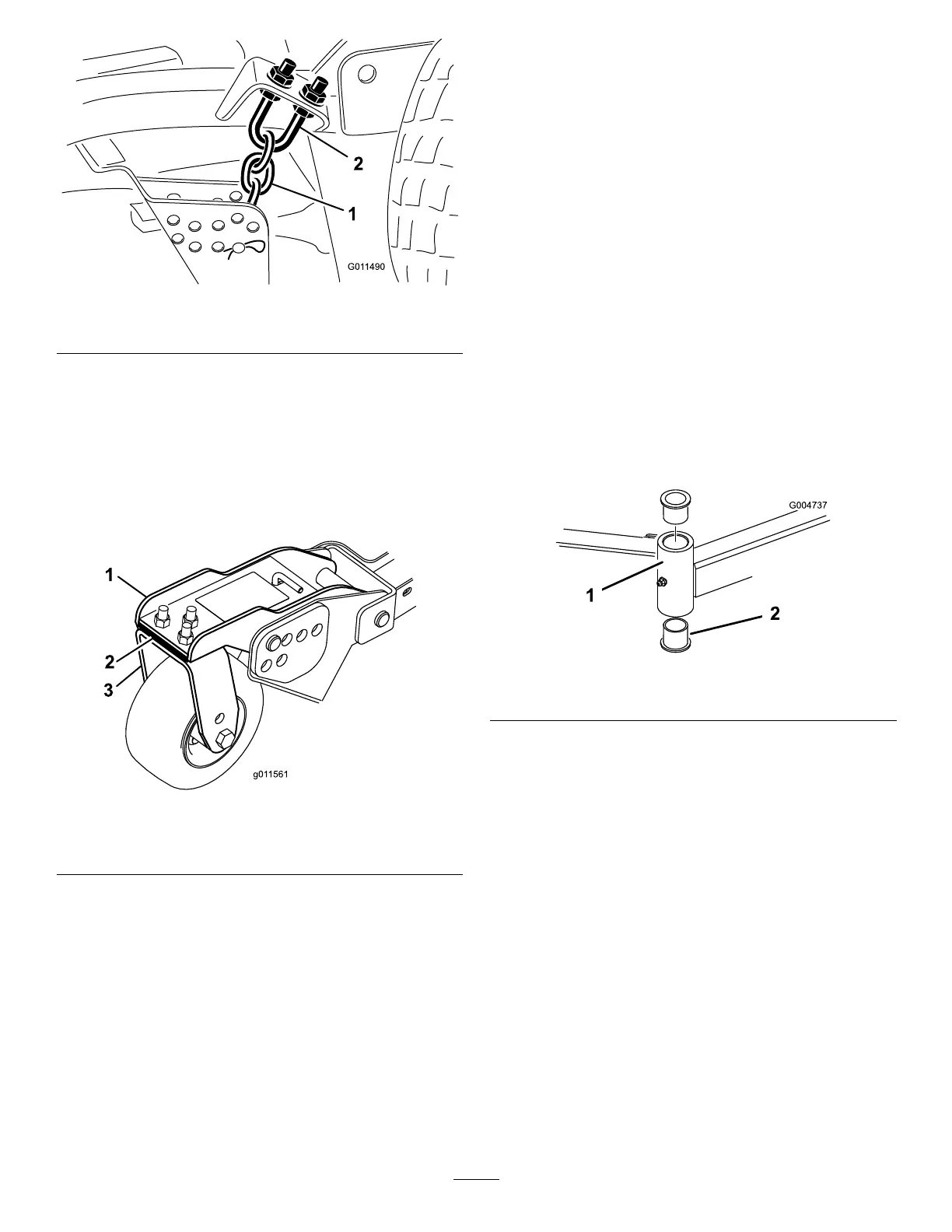

Figure81

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitifit

isdamaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

ServiceInterval:Every800hours

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(

Figure82)

orthecastorpivotarm(Figure83).Graspthecastor

wheelandslidetheboltoutoftheforkorpivotarm.

50

Loading...

Loading...