HydraulicSystem

Maintenance

ChangingtheHydraulicFluid

ServiceInterval:Aftertherst200hours

Every800hours

Changethehydraulicuidafterevery800operatinghours,

innormalconditions.Iftheuidbecomescontaminated,

contactyourlocalTorodistributorbecausethesystemmust

beushed.Contaminateduidlooksmilkyorblackwhen

comparedtocleanoil.

1.Turntheengineoffandraisethehood.

2.Loosenthedrainvalveonthebottomofthereservoir

andletthehydraulicuidowintolargedrainpan.

Closethevalvewhenthehydraulicuidstopsdraining.

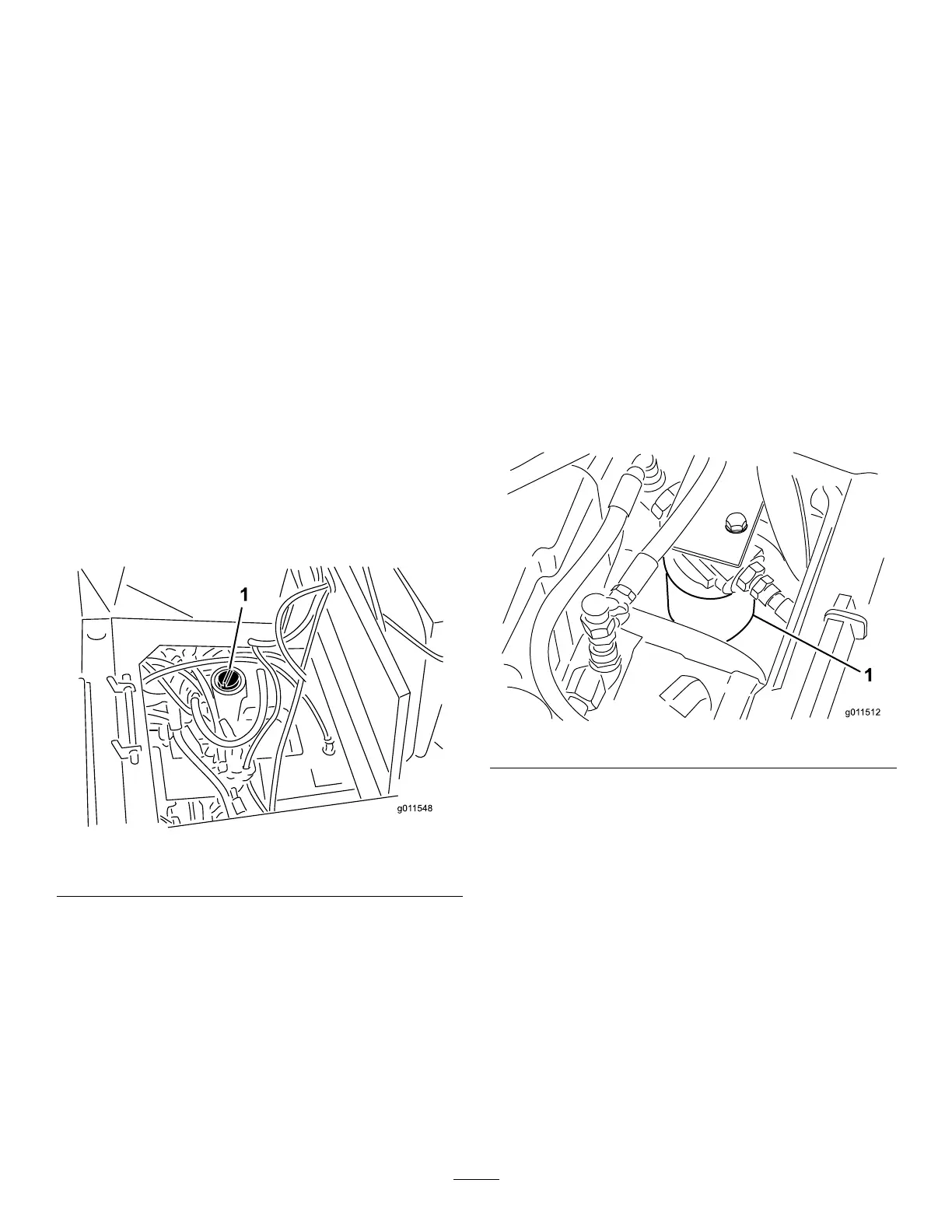

3.Fillthereservoir(

Figure74)withapproximately8

gallons(30l)ofhydraulicuid;refertoCheckingthe

HydraulicFluid.

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

Figure74

1.Hydraulicreservoir

4.Installthereservoircap.Starttheengineanduseall

ofthehydrauliccontrolstodistributehydraulicuid

throughoutthesystem.Alsocheckforleaks;thenstop

theengine.

5.Checktheuidlevelandaddenoughtoraiselevel

theleveltotheFULLmarkonthedipstick.Donot

overll.

ReplacingtheHydraulicFilters

ServiceInterval:Aftertherst200hours

Every800hours

Changethe2hydraulicltersinitiallyaftertherst200

operatinghours.Thereafter,changetheltersafterevery800

operatinghours,innormalconditions.

UseTororeplacementlters(PartNo.94-2621fortheleft

sideofthemachineand75-1310fortherightsideofthe

machine).

Important:Useofanyotherltermayvoidthewarranty

onsomecomponents.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovetheignitionkey.

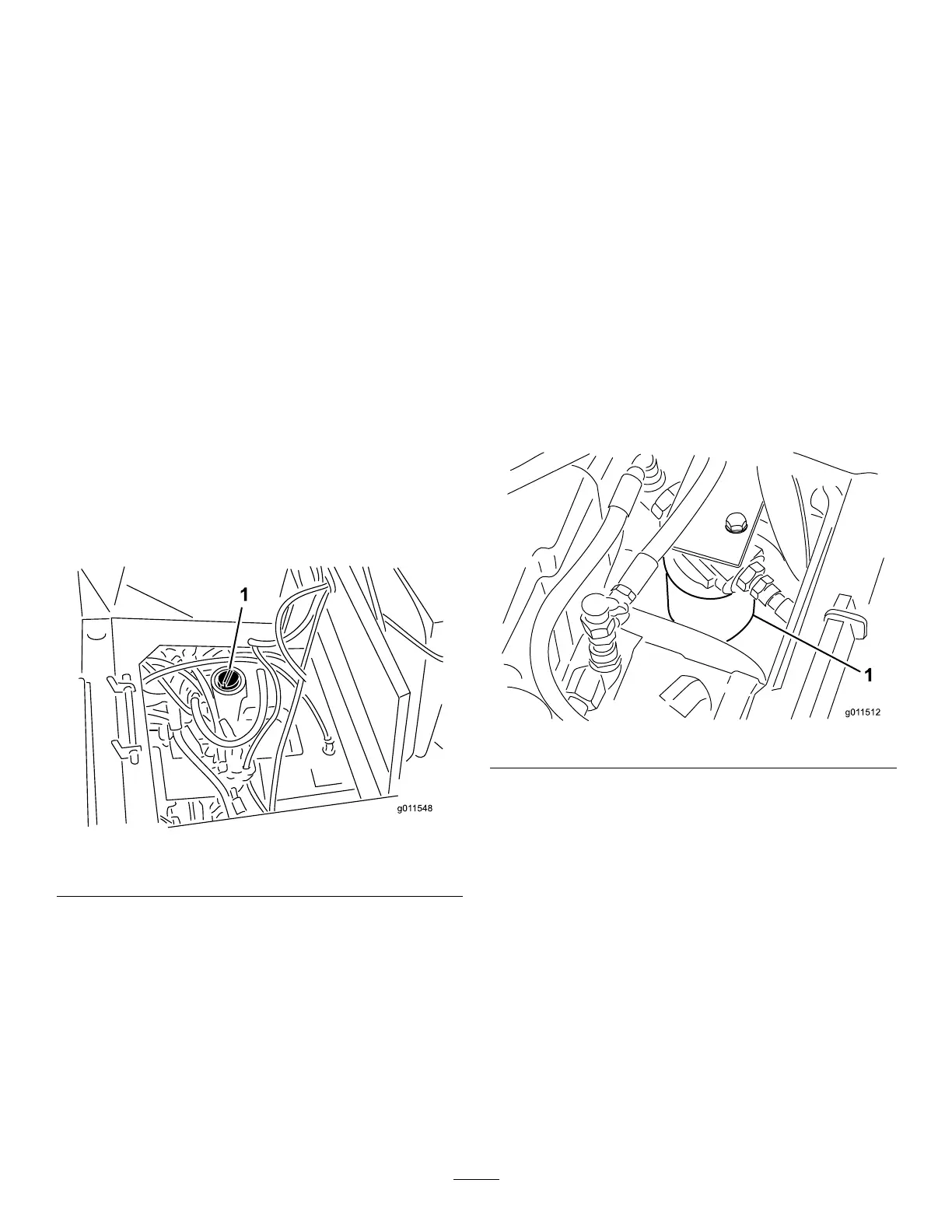

2.Cleantheareaaroundtheltermountingarea.Place

adrainpanunderthelterandremovethelter

(Figure75).

Figure75

3.Lubricatethenewltergasketandllthelterwith

hydraulicuid.

4.Ensurethattheltermountingareaisclean.Screwthe

lteronuntilthegasketcontactsthemountingplate;

thentightenthelteranadditional1/2turn.

5.Starttheengineandletitrunforabouttwominutesto

purgeairfromthesystem.Stoptheengineandcheck

forleaks.

47

Loading...

Loading...