CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

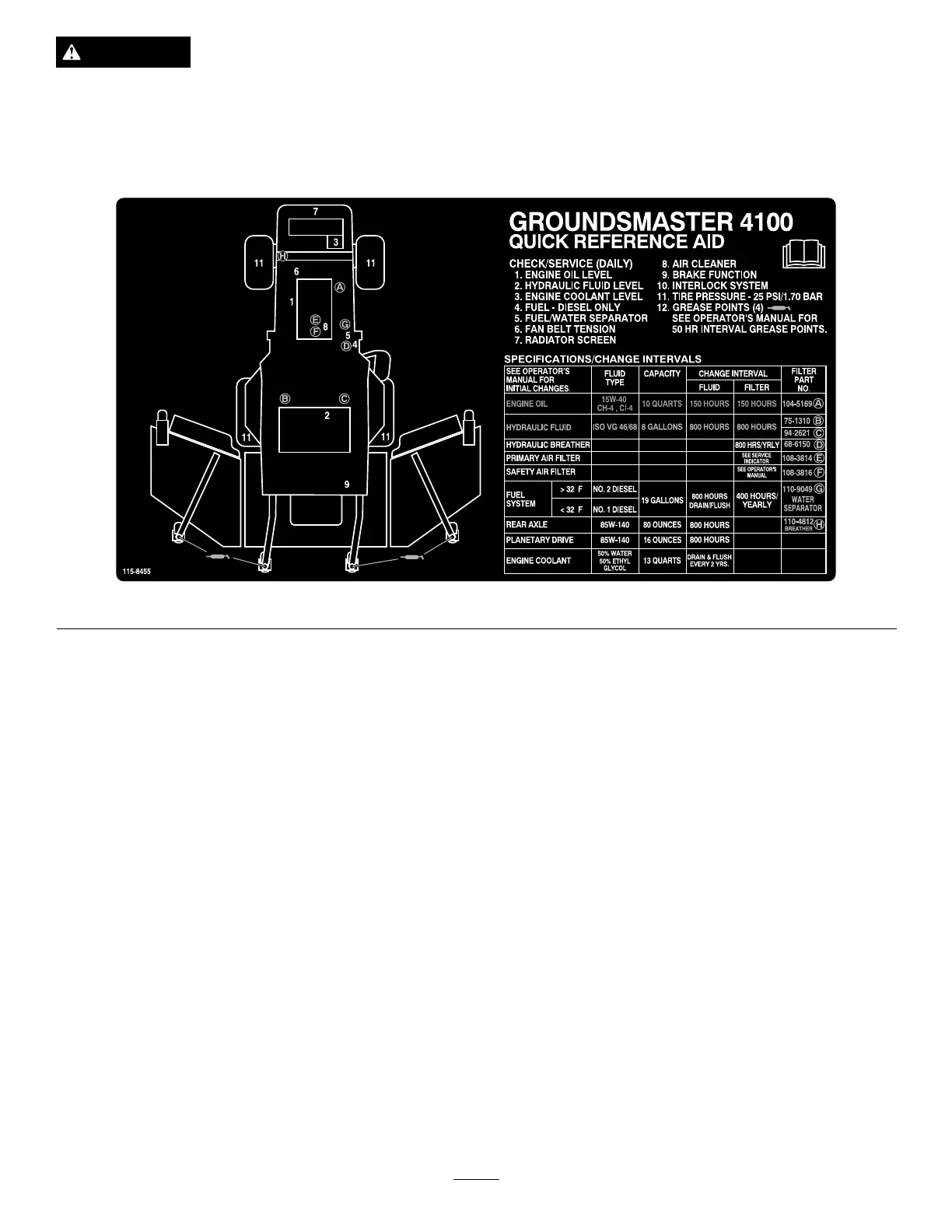

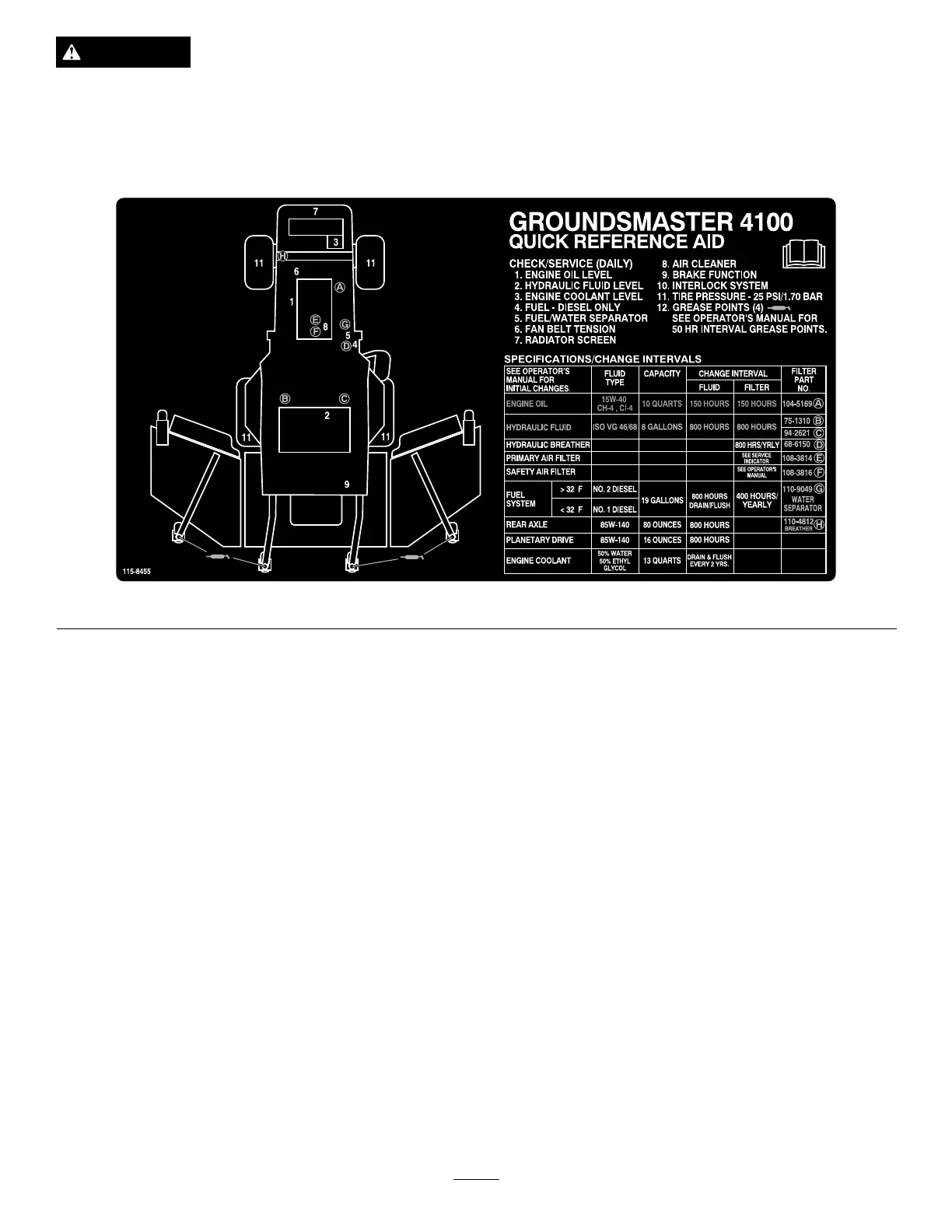

ServiceIntervalChart

Figure36

Lubrication

GreasingtheBearingsand

Bushings

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperationor

immediatelyaftereverywashing.

Bearingsrarelyfailfromdefectsinmaterialsorworkmanship.

Themostcommonreasonforfailureismoistureand

contaminationworkingitswaypasttheprotectiveseals.

Bearingsthataregreasedwillrelyuponregularmaintenance

topurgeharmfuldebrisfromthebearingarea.Sealed

bearings,suchasthecastorwheelbearings,relyonan

initialllofspecialgreaseandarobustintegralsealtokeep

contaminantsandmoistureoutoftherollingelements.

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswillprovide

goodperformanceandlifeundernormaluse,butperiodic

inspectionsofbearingconditionandsealintegrityshould

beconductedtoavoiddowntime.Thesebearingsshould

beinspectedseasonallyandreplacedifdamagedorworn.

Bearingsshouldoperatesmoothlywithnodetrimental

characteristicssuchashighheat,noise,loosenessor

indicationsofcorrosion(rust).

Duetotheoperatingconditionsthesebearing/sealpackages

aresubjectto(i.e.sand,turfchemicals,water,impacts,etc.)

theyareconsiderednormalwearitems.Bearingsthatfaildue

tocausesotherthandefectsinmaterialsorworkmanshipare

typicallynotcoveredunderwarranty.

Note:Bearinglifecanbenegativelyaffectedbyimproper

washdownprocedures.Donotwashdowntheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhighvolume

sprayatthebearings.

Thegreasettinglocationsandquantitiesare:

TractionUnit

ServiceInterval:Every50hours

•Brakeshaftpivotbearings(5)(Figure37)

•Tractionpedalpivotbushing(1)(Figure38)

32

Loading...

Loading...