BladeMaintenance

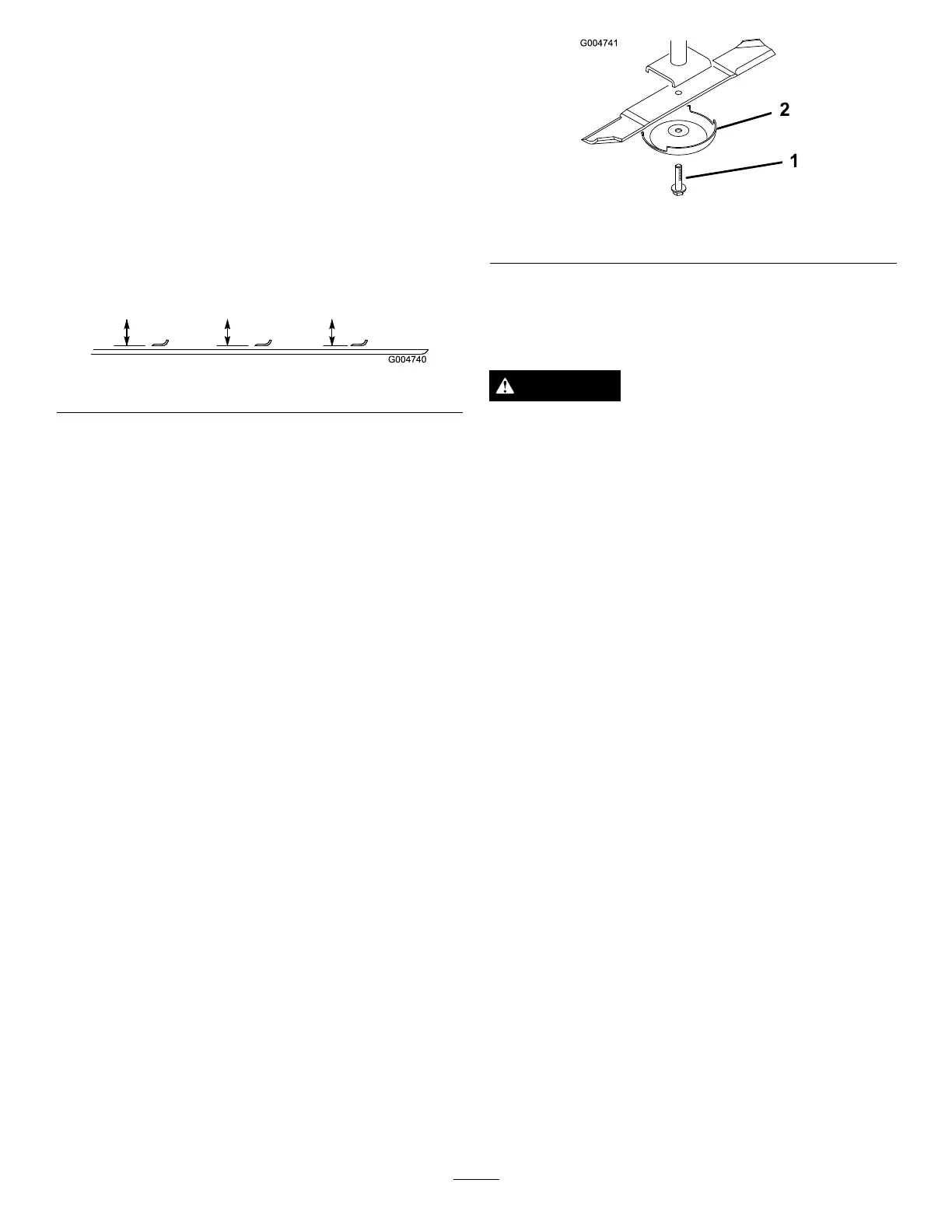

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthetraction

pedalinneutral,putthePTOleverintheOffposition,

stoptheengine,andremovetheignitionkey.Blockthe

cuttingunittopreventitfromaccidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforwardand

backward(Figure85).Measurefromtheinsideofthe

cuttingunittothecuttingedgeatthefrontoftheblade.

Rememberthisdimension.

Figure85

3.Rotatetheoppositeendofthebladeforward.Measure

betweenthecuttingunitandcuttingedgeoftheblade

atthesamepositionasinstep2.Thedifference

betweenthedimensionsobtainedinsteps2and3

mustnotexceed1/8inch(3mm).Ifthedimension

exceeds1/8inch(3mm),thebladeisbentandmustbe

replaced;refertoRemovingandInstallingtheCutter

Blade.

RemovingandInstallingthe

CutterBlade(s)

Theblademustbereplacedifasolidobjectishit,theblade

isoutofbalance,orifthebladeisbent.Alwaysusegenuine

Tororeplacementbladestobesureofsafetyandoptimum

performance.Neverusereplacementbladesmadebyother

manufacturersbecausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey.Blockthecuttingunittopreventitfrom

accidentallyfalling.

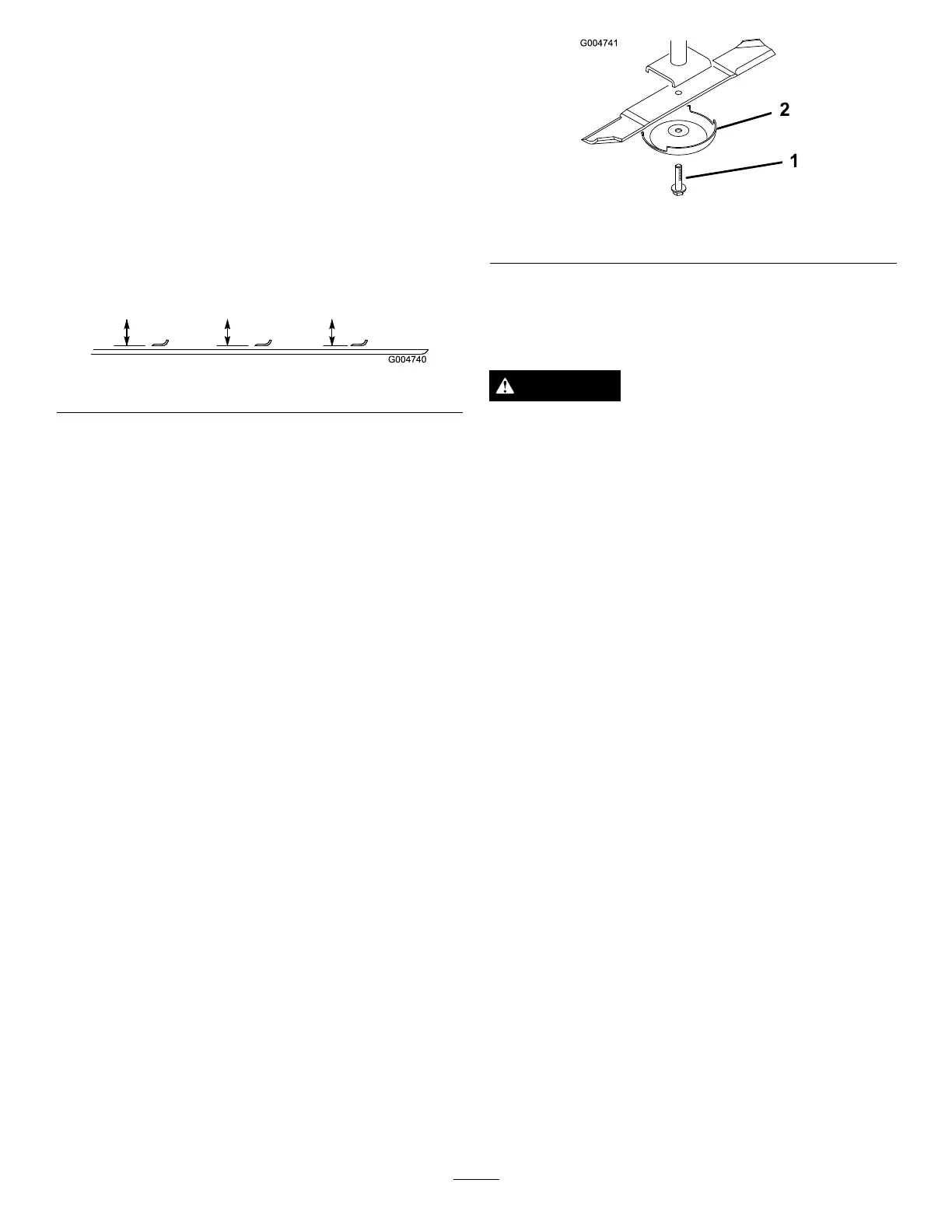

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure86).

3.Installtheblade,anti-scalpcup,andbladebolt.Tighten

thebladeboltto85to110ft-lb(115to149N⋅m).

Important:Thecurvedpartoftheblademustbe

pointingtowardtheinsideofthecuttingunitto

ensurepropercutting.

Note:Afterstrikingaforeignobject,torqueallthe

spindlepulleynutsto130to150ft-lb(176to203

N⋅m).

Figure86

1.Bladebolt2.Anti-scalpcup

InspectingandSharpeningthe

CutterBlade(s)

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.Tryingtorepairadamagedblade

mayresultindiscontinuedsafetycerticationof

theproduct.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbentor

weldabrokenorcrackedblade.

•Replaceawornordamagedblade.

Twoareasmustbeconsideredwhencheckingandservicing

thecutterblade-thesailandthecuttingedge.Bothcutting

edgesandthesail,whichistheturnedupportionopposite

thecuttingedge,contributetoagoodquality-of-cut.The

sailisimportantbecauseitliftsthegrassupstraight,thereby

producinganevencut.However,thesailwillgraduallywear

downduringoperation,andthisconditionisnormal.Asthe

sailwearsdown,thequality-of-cutwilldegradesomewhat,

althoughthecuttingedgesaresharp.Thecuttingedgeof

theblademustbesharpsothatthegrassiscutratherthan

torn.Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedgesto

correctthiscondition.

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthetraction

pedalinneutral,putthePTOleverintheOffposition,

stoptheengine,andremovetheignitionkey.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsoftheblade

meet(

Figure87).Sincesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

mower.Ifwearisnoticed(

Figure87),replacetheblade.

52

Loading...

Loading...