AdjustingtheCuttingUnitRollers

Thecuttingunitrollersshouldbemountedinthelower

positionwhenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhenoperatingin

heightofcutslowerthan2-1/2inches(64mm).

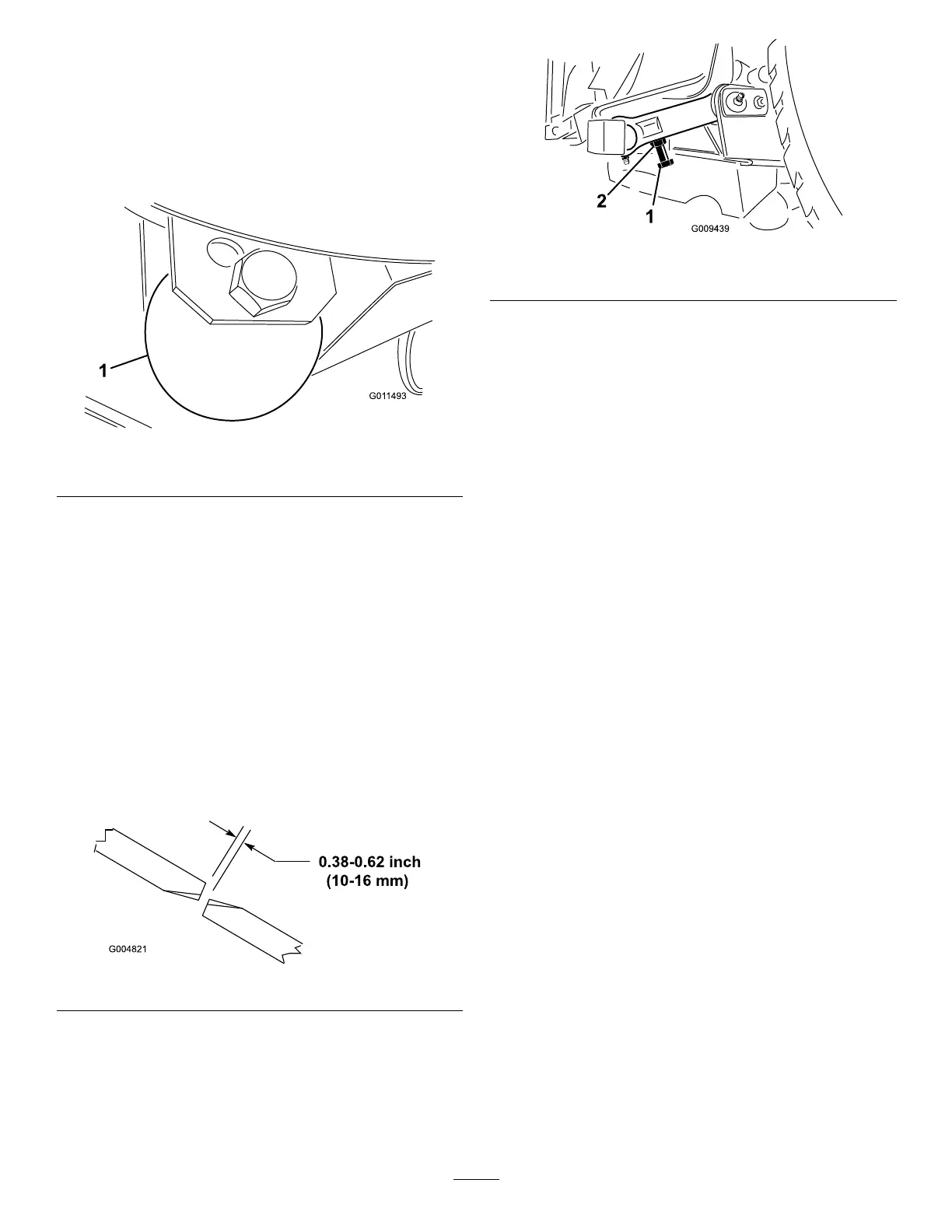

1.Removetheboltandnutsecuringthegagewheelto

thecuttingunitbrackets(Figure25).

Figure25

1.Gagewheel

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

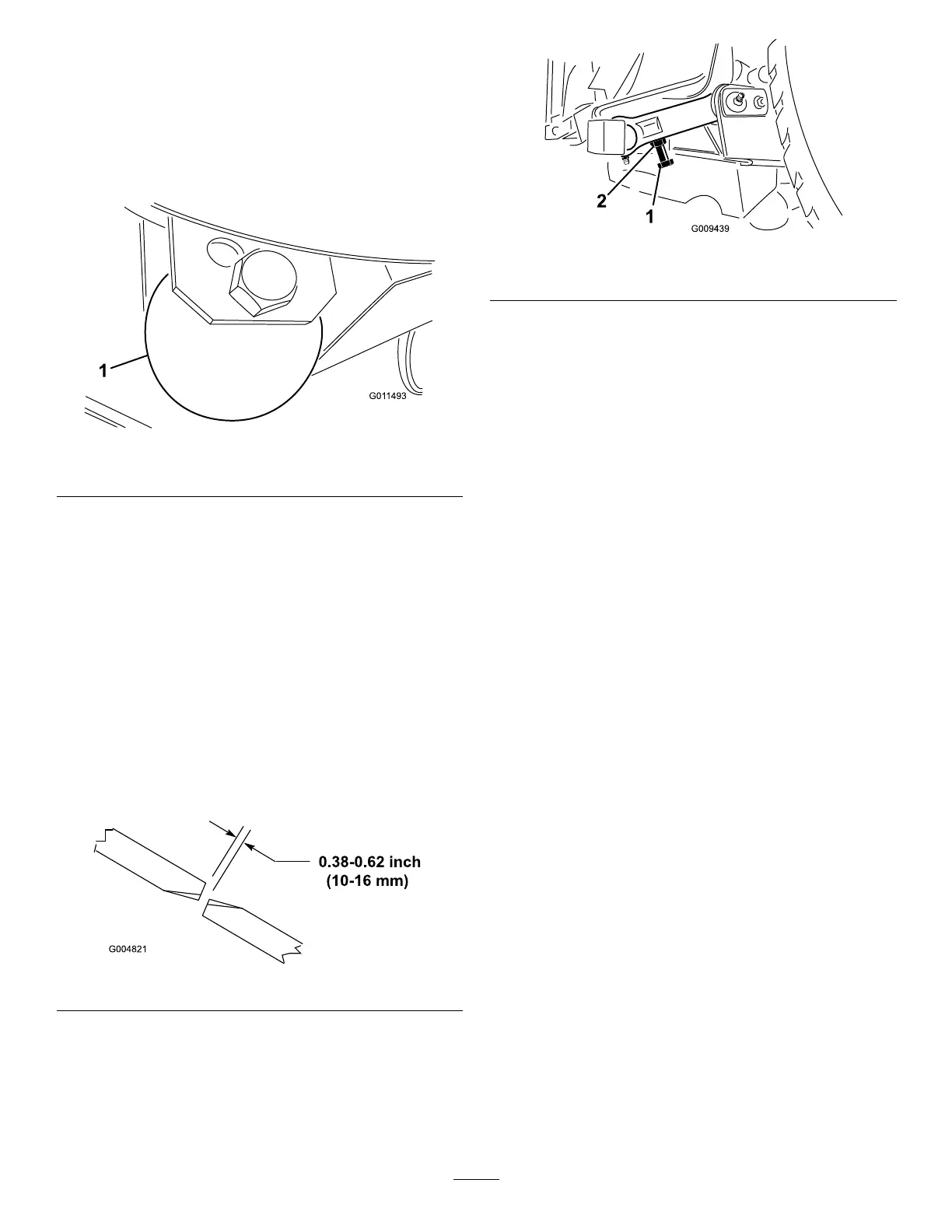

AdjustingtheBlade

Toensureproperoperationofthecuttingunit,theremustbe

0.38-0.62inch(10-16mm)clearancebetweenthetipsofthe

wingandcentercuttingunitblades(Figure26).

1.Raisecuttingunitsobladesarevisibleandblockcenter

decksectionsoitcannotfallaccidentally.Wingdecks

mustbehorizontaltocentercuttingunit.

2.Rotateacenterandadjoiningwingbladesothereblade

tipsarealigned.Measuredistancebetweenbladetips,

distanceshouldbeapproximately0.38-0.62inch(10-16

mm)(

Figure26).

Figure26

3.Toadjustdistance,locateadjusterboltonrearpivot

linkofcuttingunit(

Figure27).Loosenjamnuton

adjusterbolt.Loosenortightenadjusterboltsuntil

0.38-0.62inch(10-16mm)clearanceisattained,then

tightenjamnut.

4.Repeatprocedureonoppositesideofcuttingdeck.

Figure27

1.Adjusterbolt2.Jamnut

CorrectingMismatchBetweenCutting

Units

Duetodifferencesingrassconditionsandthecounterbalance

settingofthetractionunit,itisadvisedthatasampleareaof

grassbecutandappearancecheckedbeforeformalcutting

isstarted.

1.Setallcuttingunitstothedesiredheightofcut;referto

AdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressureto

25-30psi(172-207kPa).

3.Checkandadjustallcastortirepressuresto50psi(345

kPa).

4.Checkchargeandcounterbalancepressureswith

engineathighidleusingtestportsdenedinHydraulic

SystemsTestPorts.Adjustcounterbalancesettingtobe

230psi(1585kPa)higherthanchargepressurereading.

5.Checkforbentblades;refertoCheckingforaBent

Blade.

6.Cutgrassinatestareatodetermineifallcuttingunits

arecuttingatthesameheight.

7.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

8.Toeasemeasuringbladeplane,raisetheheightofcut

tothehighestposition;refertoAdjustingtheHeight

ofCut.

9.Lowercuttingunitsontotheatsurface.Removethe

coversfromthetopofthecuttingunits.

10.Loosentheangenut,securingtheidlerpulley,to

releasethebelttensiononeachcuttingunit.

CenterCuttingUnitSetup

Rotatebladeoneachspindleuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipofthe

cuttingedge.Adjust1/8inchshimsonfrontcastorfork(s)to

matchheightofcuttodecal(Figure28);refertoAdjusting

theCuttingUnitPitch.

25

Loading...

Loading...