ontothespindleshafttogetthedesiredheight-of-cut;

thenslidethewasherontotheshaft.

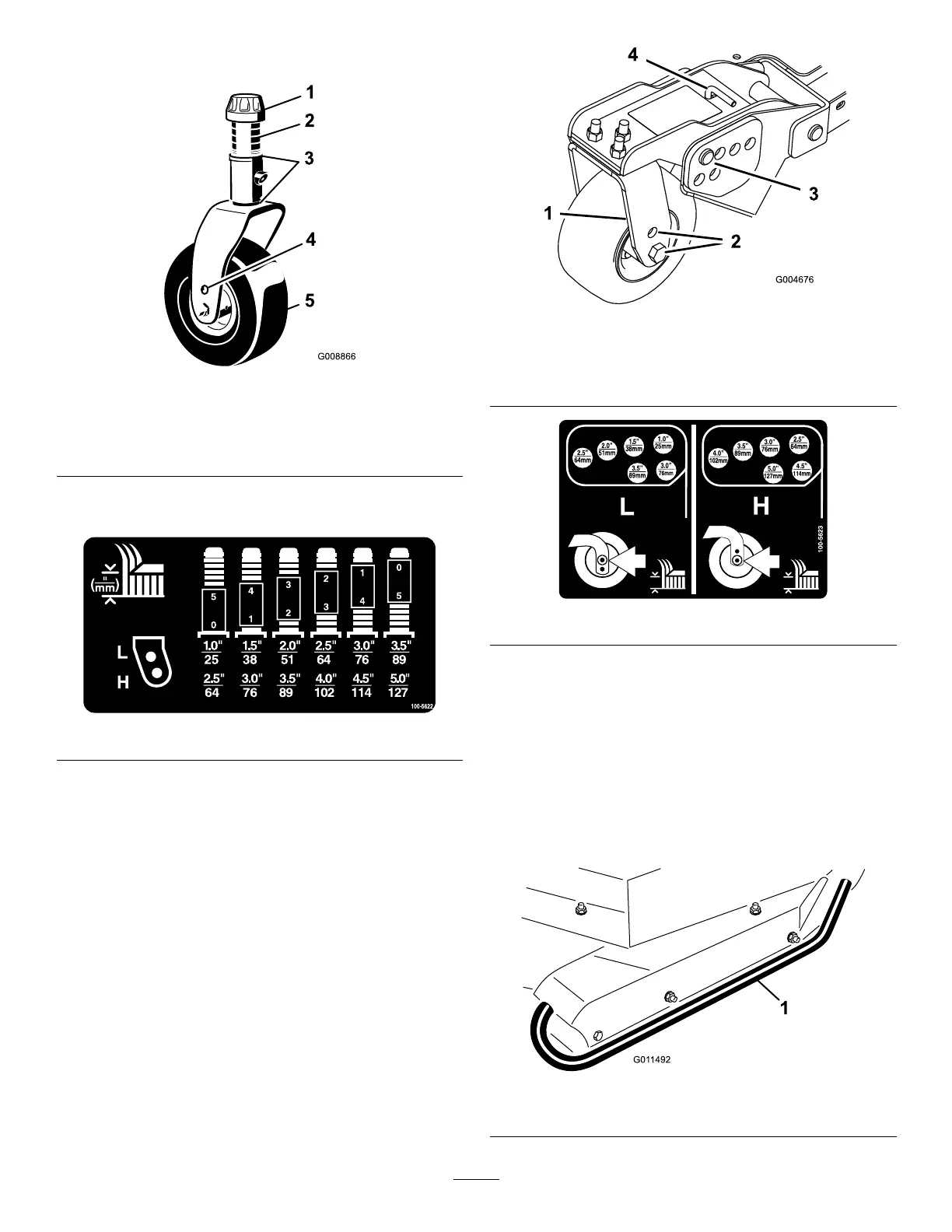

Figure20

1.T ensioningcap4.T opaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

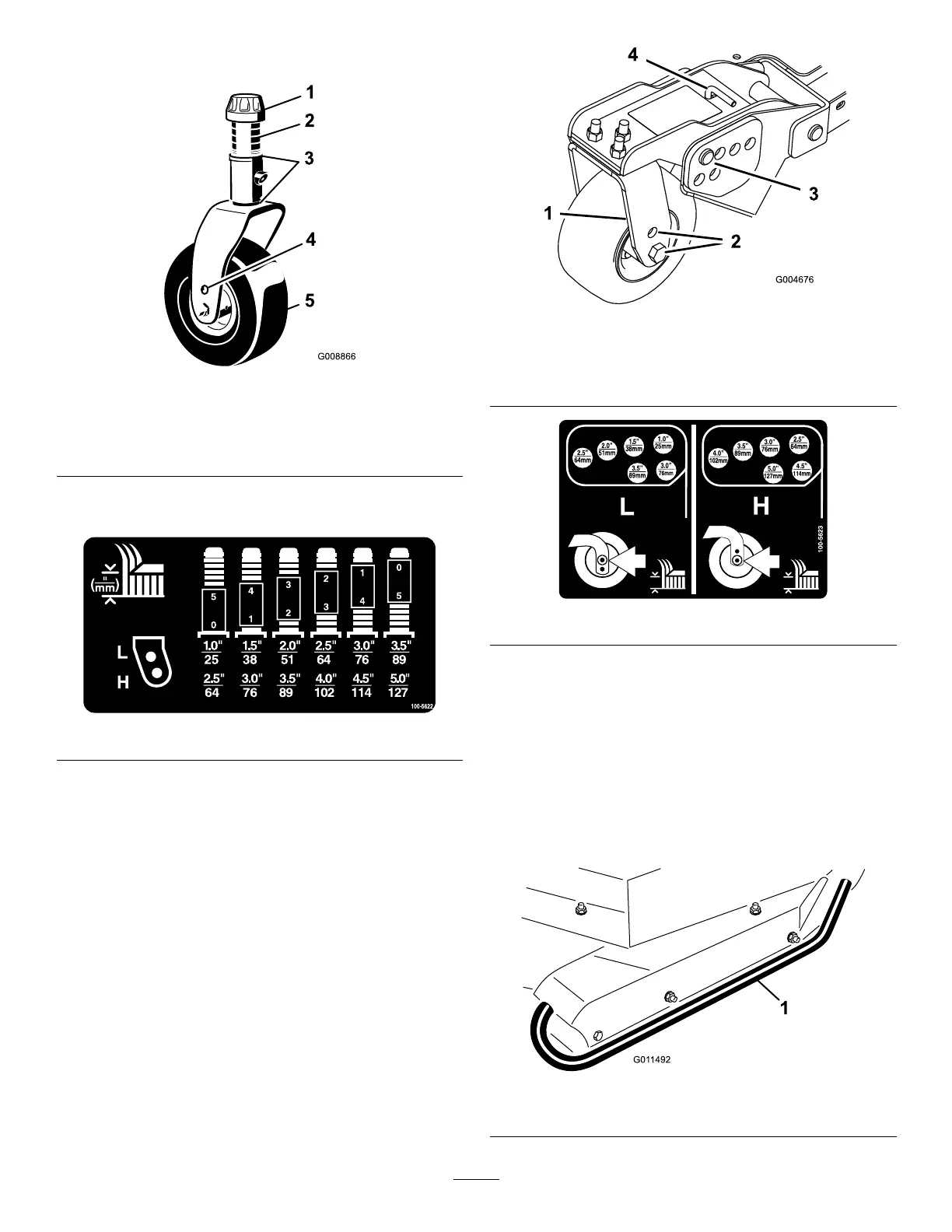

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

Figure21

3.Pushthecastorspindlethroughthecastorarm.Install

theshims(asoriginallyinstalled)andtheremaining

spacersontothespindleshaft.Installthetensioning

captosecuretheassembly.

4.Removethehairpincotterandclevispinsfromthe

castorpivotarms(Figure22).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure22and

Figure23).

6.Inserttheclevispinsandinstallthehairpincotters.

7.Rotatetensionrodcounterclockwise(ngertight)to

puttensiononadjustment.

Figure22

1.Castorpivotarm3.Clevispinandhairpin

cotter

2.Axlemountingholes4.T ensionrod

Figure23

AdjustingtheSkids

Theskidsshouldbemountedinthelowerpositionwhen

operatinginheightofcutsgreaterthan2-1/2inches(64mm)

andinthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(Figure24).

Figure24

1.Skid

24

Loading...

Loading...