Note:Rememberthelocationofthespacersoneach

forktoensurecorrectinstallation,andtomaintaina

leveldeck.

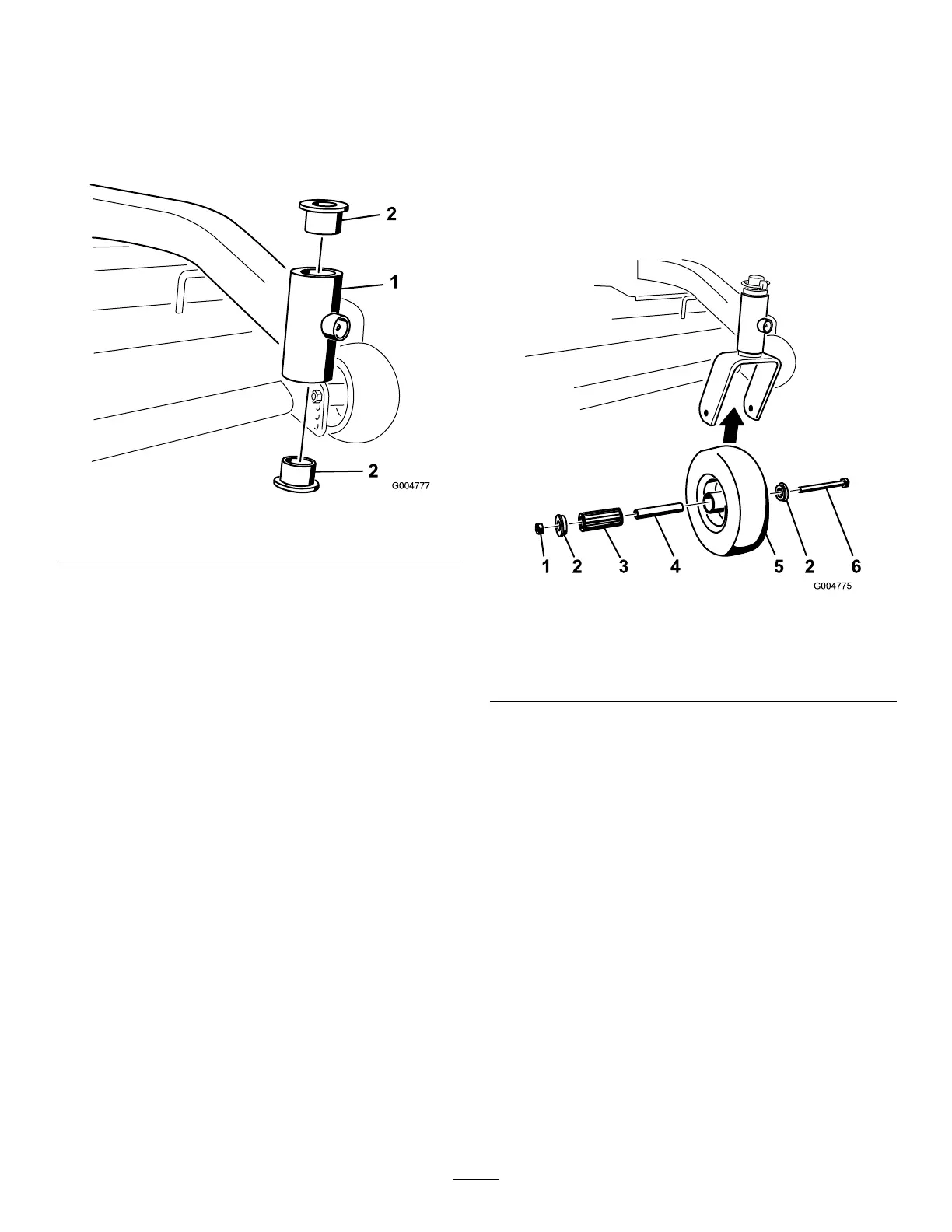

4.Insertapinpunchintothemountingtubeandcarefully

driveoutthebushings(Figure45).

5.Cleantheinsideofthemountingtube.

Figure45

1.Mountingtube2.Bushing

6.Greasetheinsideandoutsideofthenewbushings.

Note:Useahammerandatplatetocarefullydrive

thebushingsintothepivottubes.

7.Inspectthecaster-wheelforkforwear,andreplaceif

necessary(Figure44).

8.Slidethecaster-wheelforkthroughthebushingsinthe

mountingtube.

9.Replacethespacer(s)ontotheforkandsecurewiththe

retainingring(Figure44).

Important:Theinsidediameterofthebushings

maycollapseslightlywheninstalled.Ifthe

caster-wheelforkdoesnotslideintothenew

bushings,reambothbushingstoaninside

diameterof29mm(1.1inches).

10.Greasethettingonthecarrierframepivottubes

usingNo.2generalpurposelithiumbaseor

molybdenum-basegrease.

ServicingtheCasterWheel

andBearings

Thecasterwheelsrotateonarollerbearingsupportedbya

spannerbushing.Ifthebearingiskeptwelllubricated,wear

willbeminimal.Failuretokeepthebearingwelllubricated

willcauserapidwear.Awobblycasterwheelusuallyindicates

awornbearing.

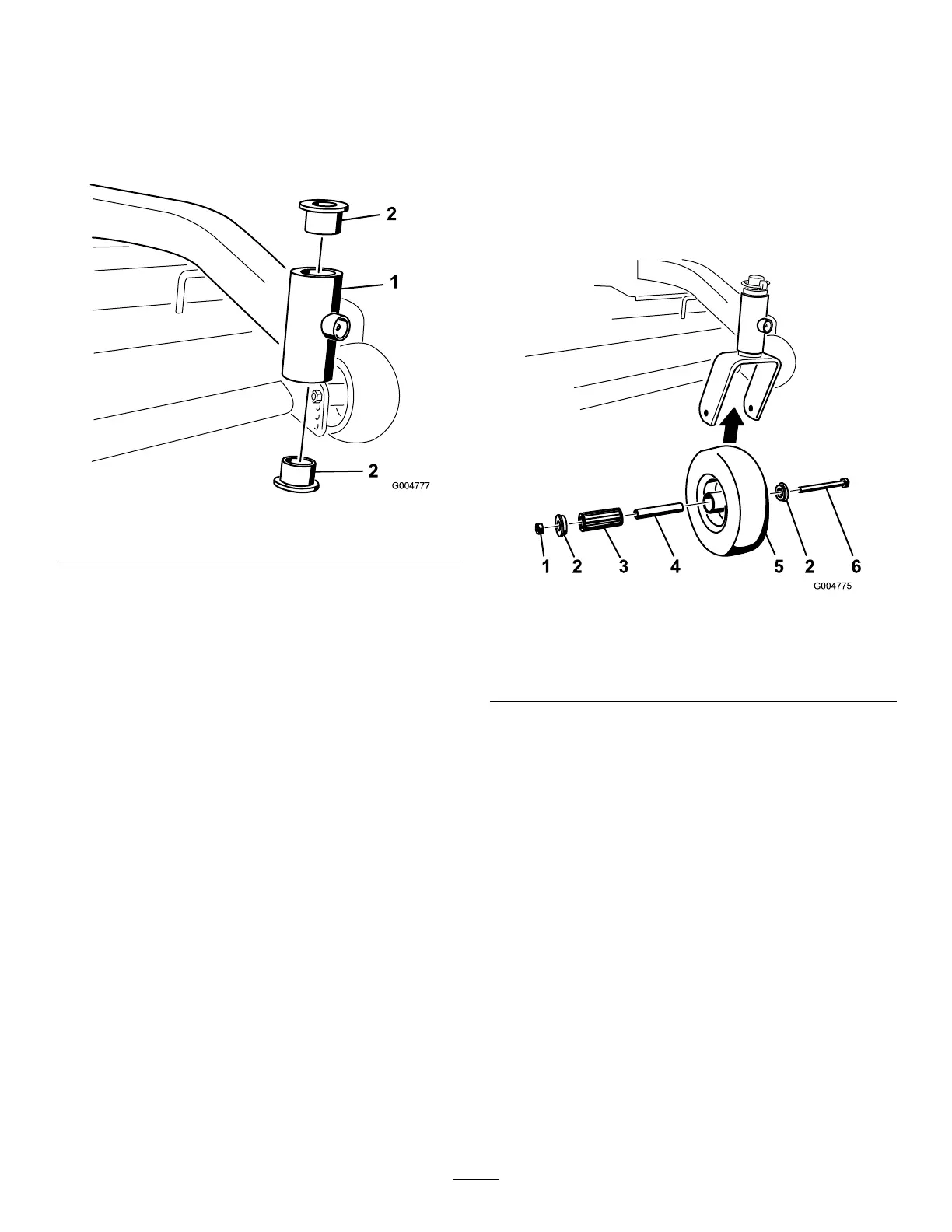

1.Removethelocknutandwheelboltholdingthecaster

wheeltothecasterfork(Figure46).

Figure46

1.Locknut

4.Spannerbushing

2.Wheelbolt5.Rollerbearing

3.Bushing

2.Removeonebushing,thenpullthespannerbushing

andtherollerbearingoutofthewheelhub(Figure46).

3.Removetheotherbushingfromthewheelhuband

cleananygreaseanddirtfromthewheelhub(Figure

46).

4.Inspecttherollerbearing,bushings,spannerbushing

andtheinsideofthewheelhubforwear.Replaceany

defectiveorwornparts(Figure46).

5.Toassemble,placeonebushingintothewheelhub.

6.Greasetherollerbearingandspannerbushingandslide

themintothewheelhub.

7.Placethesecondbushingintothewheelhub(Figure

46).

8.Installthecasterwheelintothecasterfork,andsecure

withthewheelboltandlocknut.

9.Tightenthelocknutuntilthespannerbushingbottoms

againsttheinsideofthecasterforks(Figure46).

10.Greasethettingonthecasterwheel.

35

Loading...

Loading...