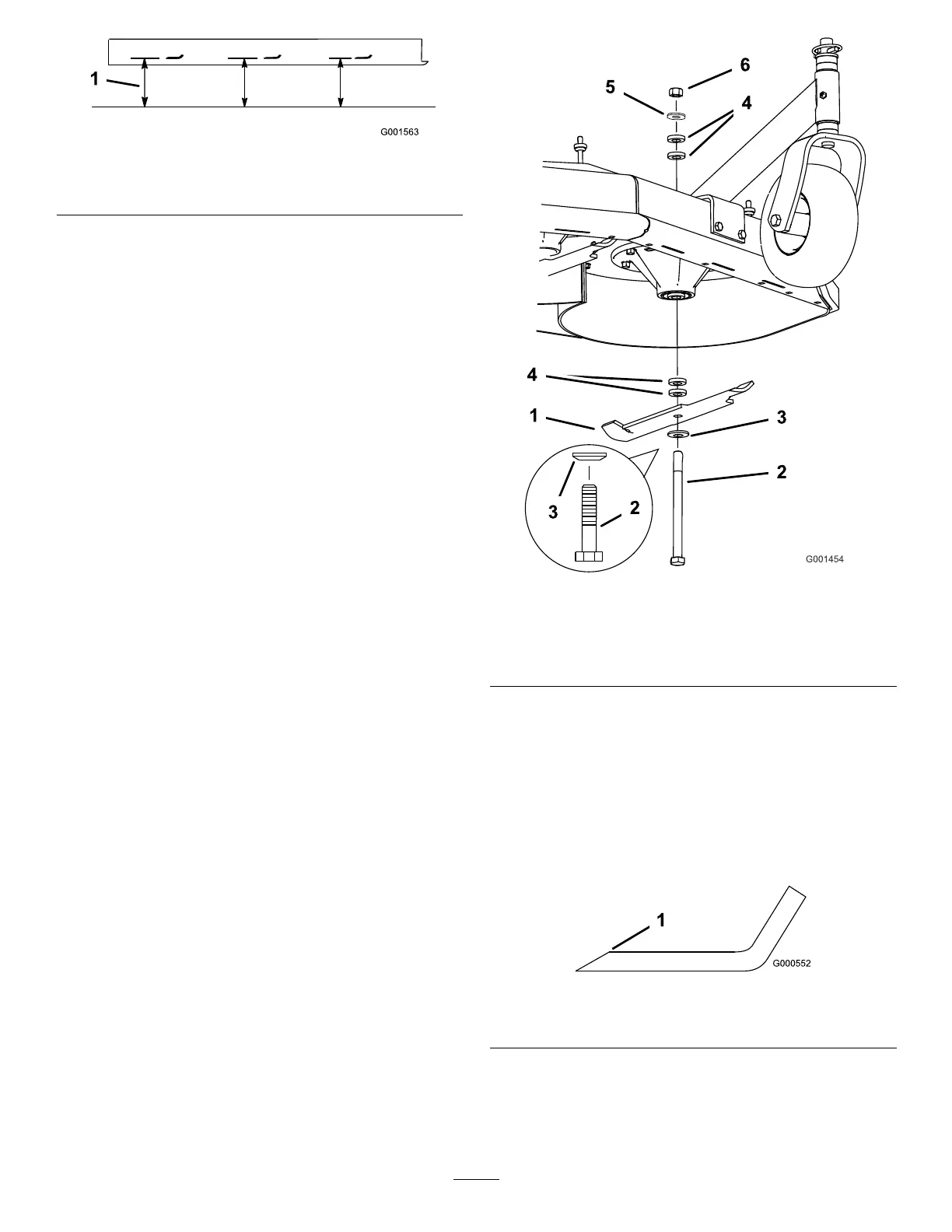

g001563

Figure50

1.Measurefromthecuttingedgetoalevelsurface.

3.Rotatetheoppositeendsofthebladesforward.

4.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep1.

Note:Thedifferencebetweenthedimensions

obtainedinsteps1and2mustnotexceed3mm

(1/8inch).Ifthisdimensionexceeds3mm(1/8

inch),thebladeisbentandmustbereplaced;

refertoRemovingtheBlades(page41)and

InstallingtheBlades(page42).

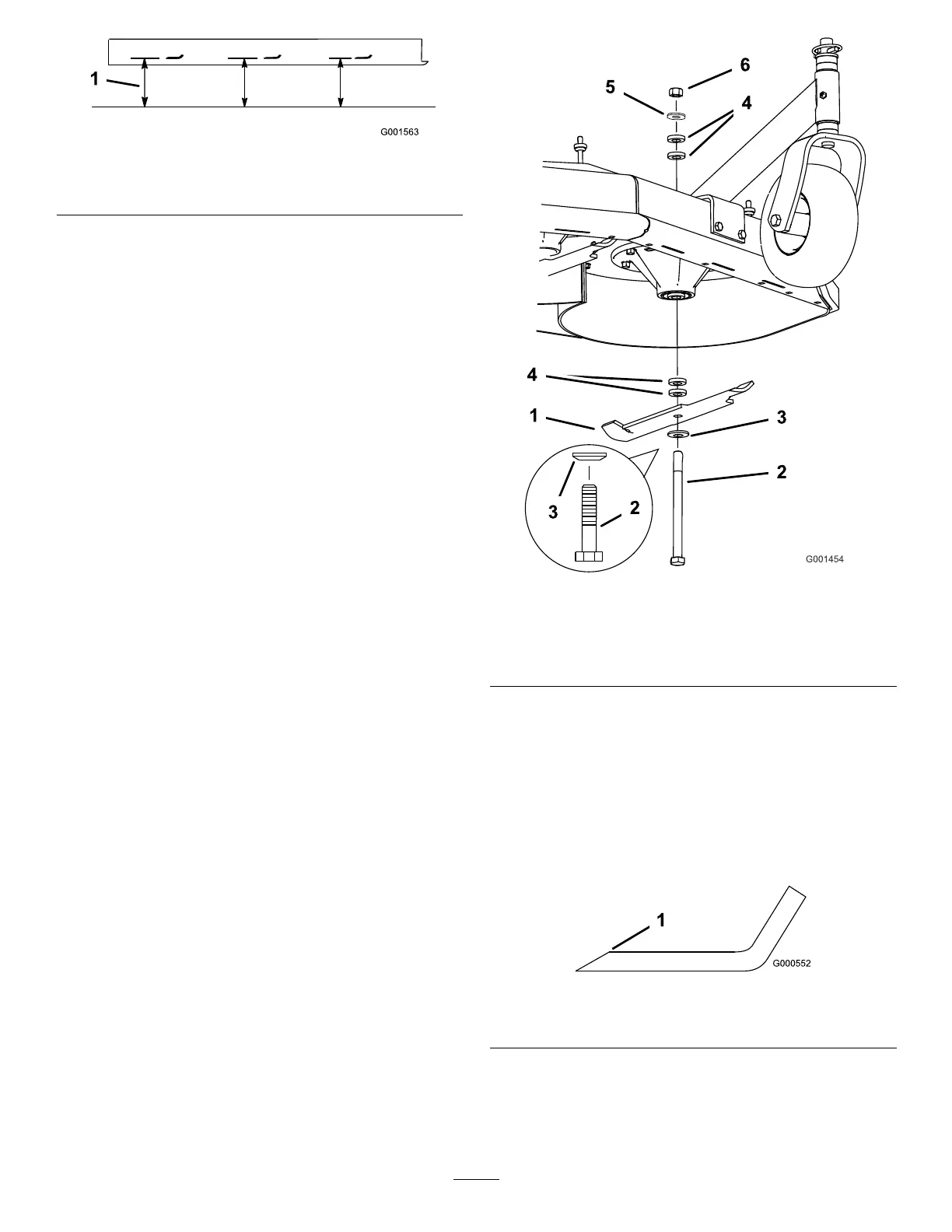

RemovingtheBlades

Replacethebladesifyouhitasolidobjectorifthe

bladesareoutofbalanceorbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

1.Holdthebladeboltwithawrench.

2.Removethenut,bladebolt,curvedwasher,

blade,spacers,andthinwasherfromthespindle

(Figure51).

g001454

Figure51

1.Blade

4.Spacer

2.Bladebolt5.Thinwasher

3.Curvedwasher

6.Nut

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure52).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

g000552

Figure52

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure53).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalancedandcanbeused.

41

Loading...

Loading...