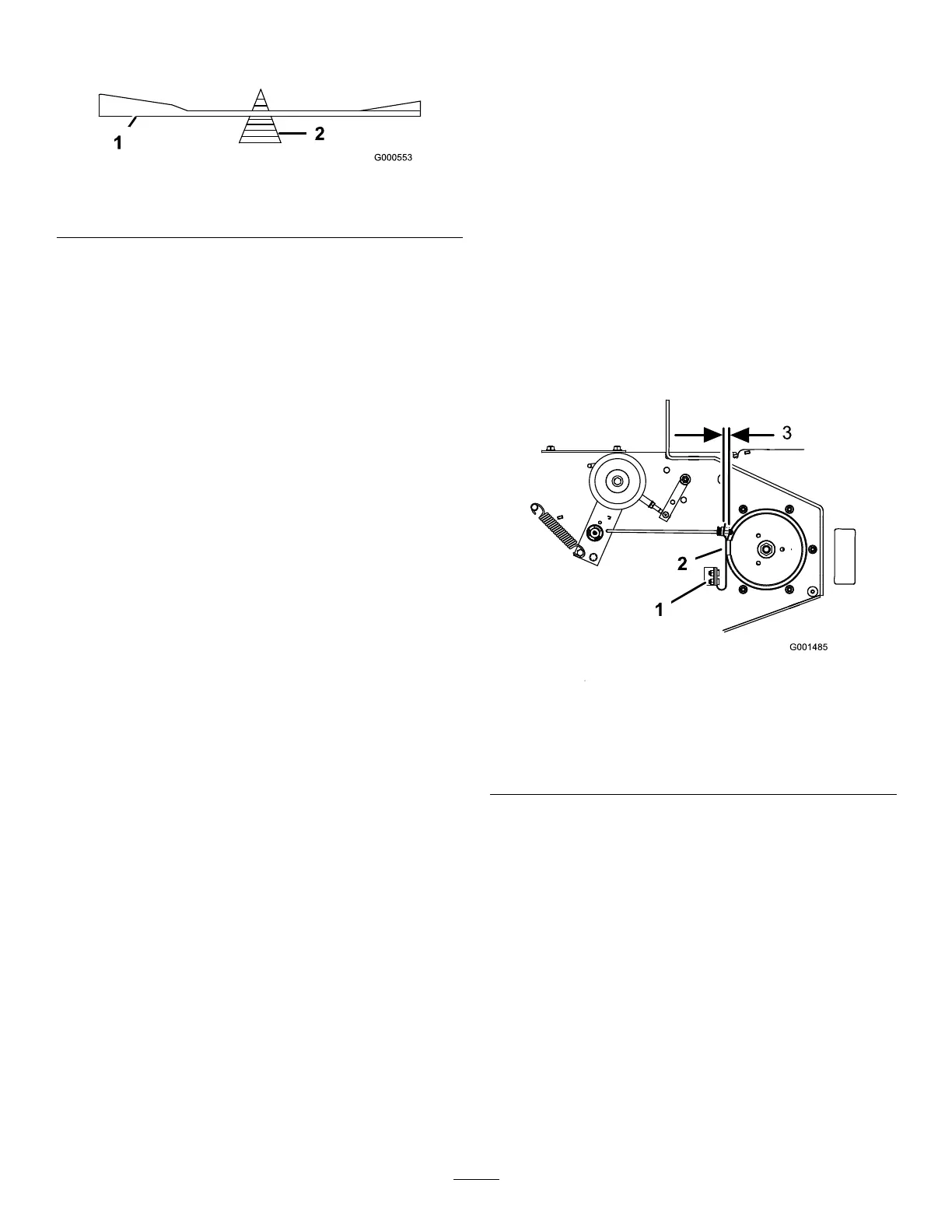

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure52).

g000553

Figure53

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeis

balanced.

InstallingtheBlades

1.Installthecurvedwasherandthentheblade

ontothebolt.Selectthepropernumberof

spacer(s)fortheheightofcut,andslidethebolt

intothespindle(Figure51).

Important:Thecurvedpartoftheblade

mustpointupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installtheremainingspacer(s)andsecurethem

withathinwasherandanut(Figure51).

3.Torquethebladeboltto101to108N∙m(75to

80ft-lb).

AdjustingtheBladeBrake

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

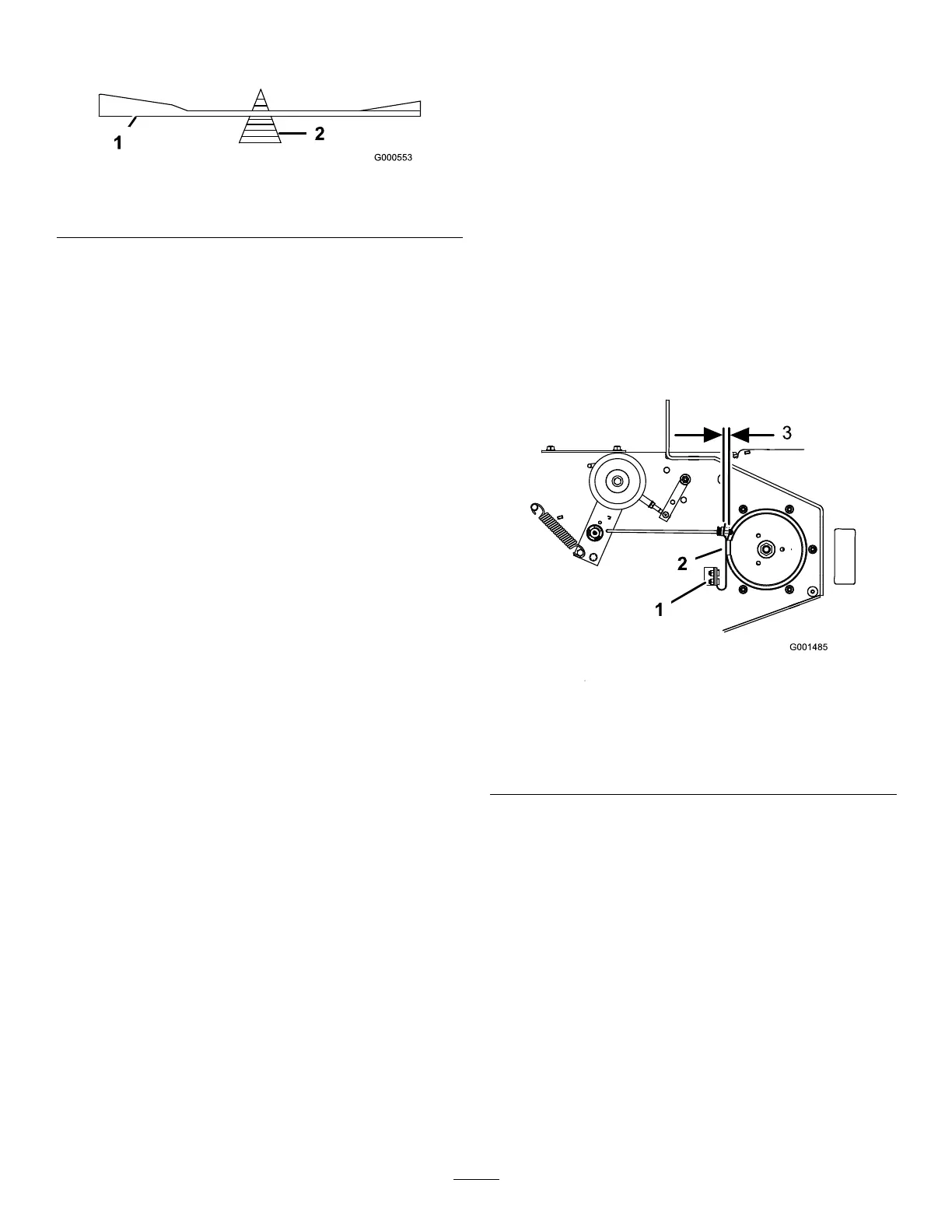

3.Ifnecessary,adjustthespring-mountingboltsso

thattheblade-brakepadrubsagainstbothsides

ofthepulleygroove(Figure54).

4.Adjustthenutattheendofthebladebrakerod

untilthereis3mmto5mm(1/8to3/16inch)

betweenthenutandspacer(Figure54).

5.Engagetheblades.

Note:Ensurethattheblade-brakepadno

longercontactsthepulleygroove.

g001485

Figure54

1.Spring-mountingbolts3.3mmto5mm(1/8to

3/16inch)

2.Blade-brakepad

42

Loading...

Loading...