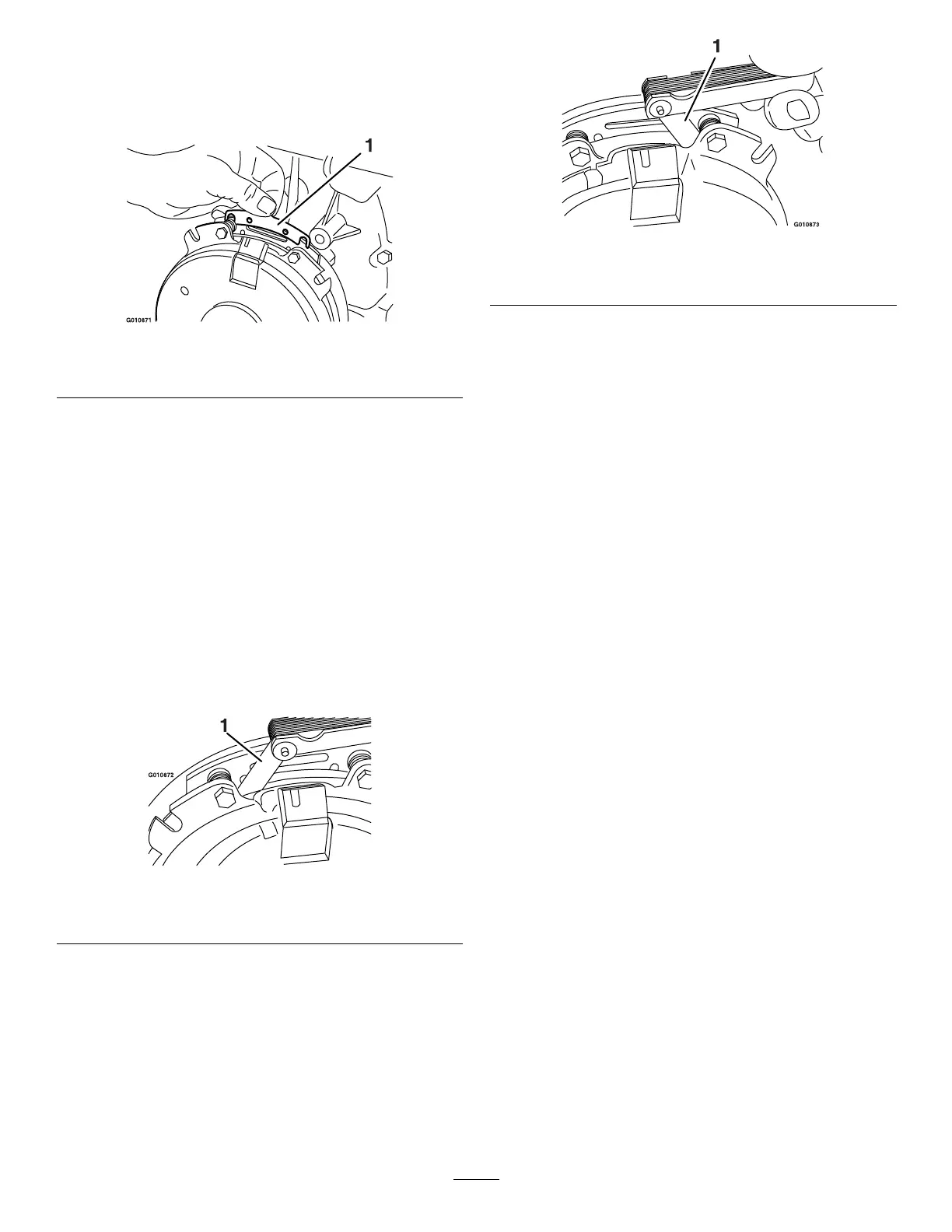

B. Using needle-nose pliers, or by hand, hold

the tab and remove the shim ( Figure 90 ).

Note: Do not discard the shim until the

clutch is functioning properly .

g010871

Figure 90

1. Shim

C. Using a pneumatic line, blow out any debris

from under the brake pole and around the

brake spacers.

D. T orque each bolt (M6 x 1) to 12.3 to 13.7

N∙m (9.5 to 10.5 ft-lb).

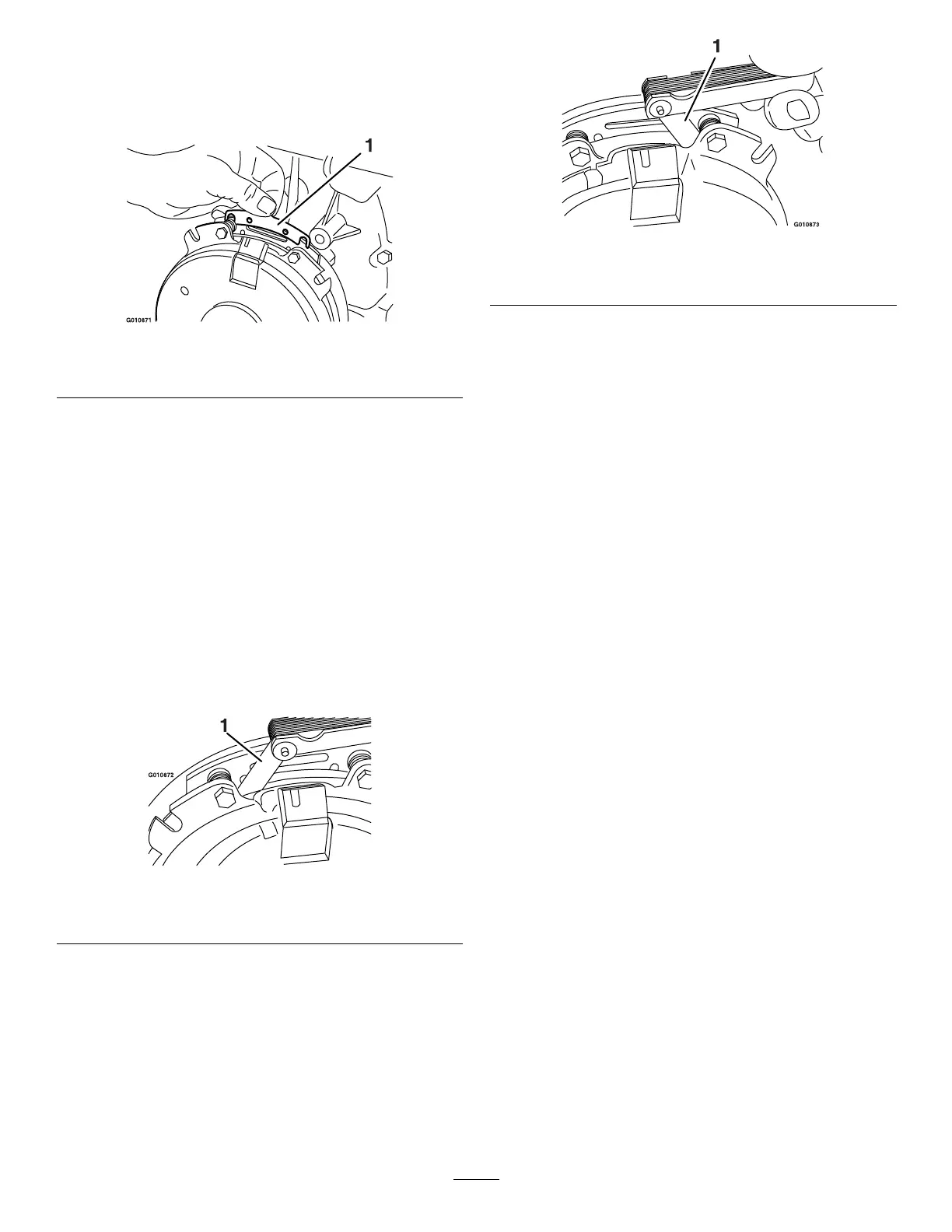

E. Using a 0.25 mm (0.01 inch) thick feeler

gauge, verify that a gap is present between

the rotor and the armature face on both

sides of the brake pole as shown in Figure

91 and Figure 92 .

Note: Due to the way the rotor and the

armature faces wear (peaks and valleys) it

is sometimes dif cult to measure the gap

accurately .

g010872

Figure 91

1. Feeler gauge

g010873

Figure 92

1. Feeler gauge

• If the gap is less than 0.25 mm (0.01

inch), then install the shim.

• If the gap is suf cient, proceed to the

safety check in step F .

F . Perform the following safety check:

i. Sit on the seat and start the engine.

ii. Make sure that the blades do not

engage with the blade-control switch

(PT O) in the O FF position, and that

the clutch is disengaged.

If the clutch does not disengage,

install the shim again.

iii. Engage and disengage the

blade-control switch (PT O) 10

consecutive times to ensure that the

clutch is functioning properly .

64

Loading...

Loading...