2.Removeonebushing,thenpullthespannerbushing

androllerbearingoutofthewheelhub(Figure61).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheelhub

(Figure61).

4.Inspecttherollerbearing,bushings,spannerbushing

andinsideofthewheelhubforwear.Replaceany

defectiveorwornparts(Figure61).

5.Toassemble,placeonebushingintothewheelhub.

Greasetherollerbearingandspannerbushingandslide

themintothewheelhub.Placethesecondbushing

intothewheelhub(Figure61).

6.Installthecasterwheelintothecasterforkandsecure

withthewheelboltandlocknut.Tightenthelocknut

untilthespannerbushingbottomsagainsttheinsideof

thecasterforks(

Figure61).

7.Greasethettingonthecasterwheel.

AdjustingtheElectricClutch

ServiceInterval:Every100hours—Checktheelectric

clutch.

Theclutchisadjustabletoensureproperengagementand

properbraking.

1.Inserta0.015–0.021inch(0.381-0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

Thegapneedstobeatleast.015inches(0.381mm)

andnotmorethan.021inches(0.533mm).

2.Ifadjustmentisneeded,usea.015inch(0.381mm)

feelergaugetoseteachofthethreeadjustmentslot

positions.Tightenthelocknutsuntilthereisslight

bindingonthefeelergaugebutitcanbemovedeasily

withintheairgap(

Figure62).

3.Repeatthisfortheremainingslots.

4.Checkeachslotagainandmakeslightadjustmentsuntil

thefeelergaugebetweentherotorandarmaturewith

veryslightcontactbetweenthem.

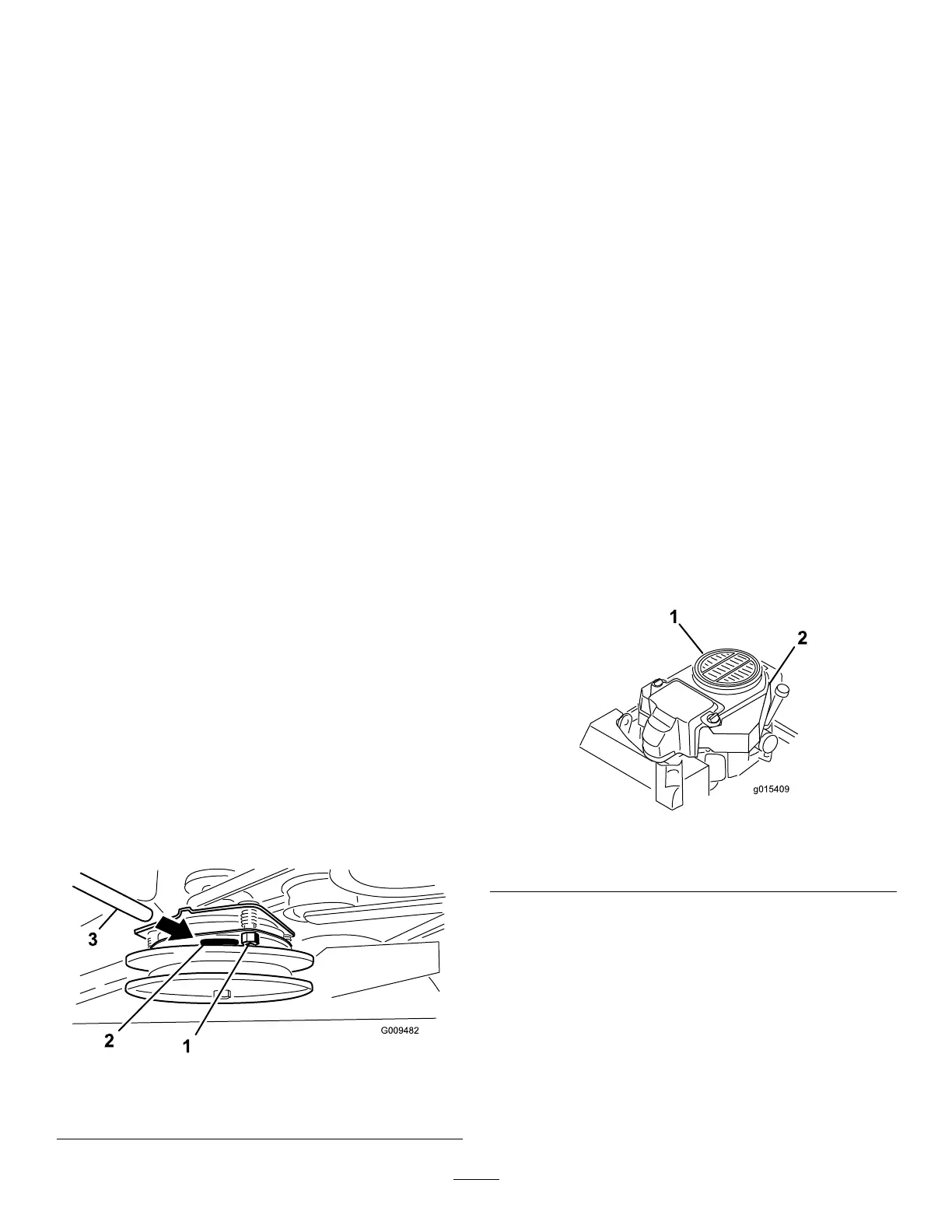

Figure62

1.Adjustingnut3.Feelergauge

2.Slot

CoolingSystem

Maintenance

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirtorother

debrisfromthecylinderandcylinderheadcoolingns,air

intakescreenonywheelend,andcarburetor-governor

leversandlinkage.Thiswillhelpinsureadequatecooling

andcorrectenginespeedandwillreducethepossibilityof

overheatingandmechanicaldamagetotheengine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours—Checkandcleanengine

coolingnsandshrouds.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreenandfanhousing

(Figure63).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(Figure63).

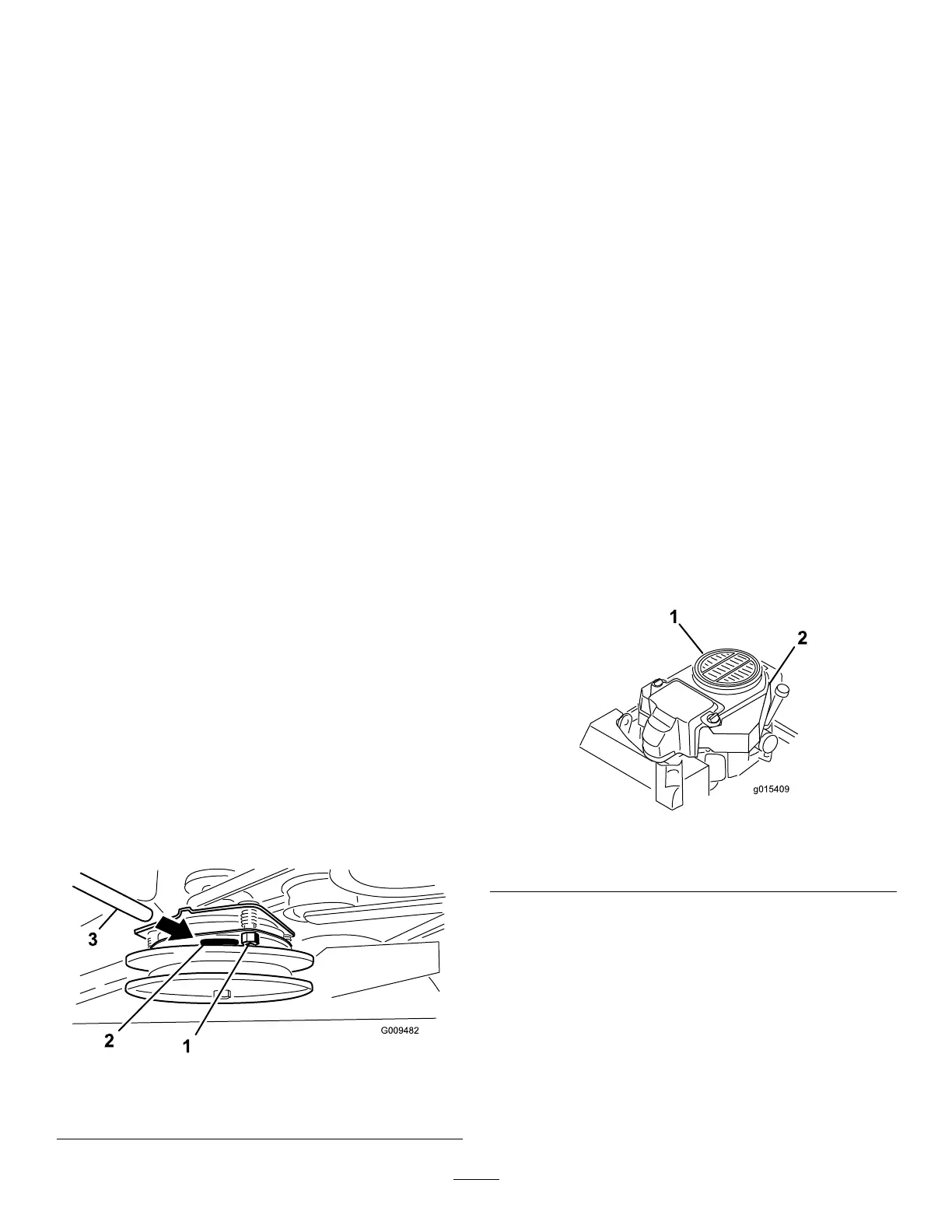

Figure63

1.Guardandengineair

intakescreen

2.Fanhousing

CleaningtheHydraulicOil

Cooler(52and60inchMower

ModelsOnly)

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirtorother

debrisfromthehydraulicoilcoolerandfan.Thiswillhelp

insureadequatecoolingandcorrectenginespeedandwill

reducethepossibilityofoverheatingandmechanicaldamage

totheengine.

42

Loading...

Loading...