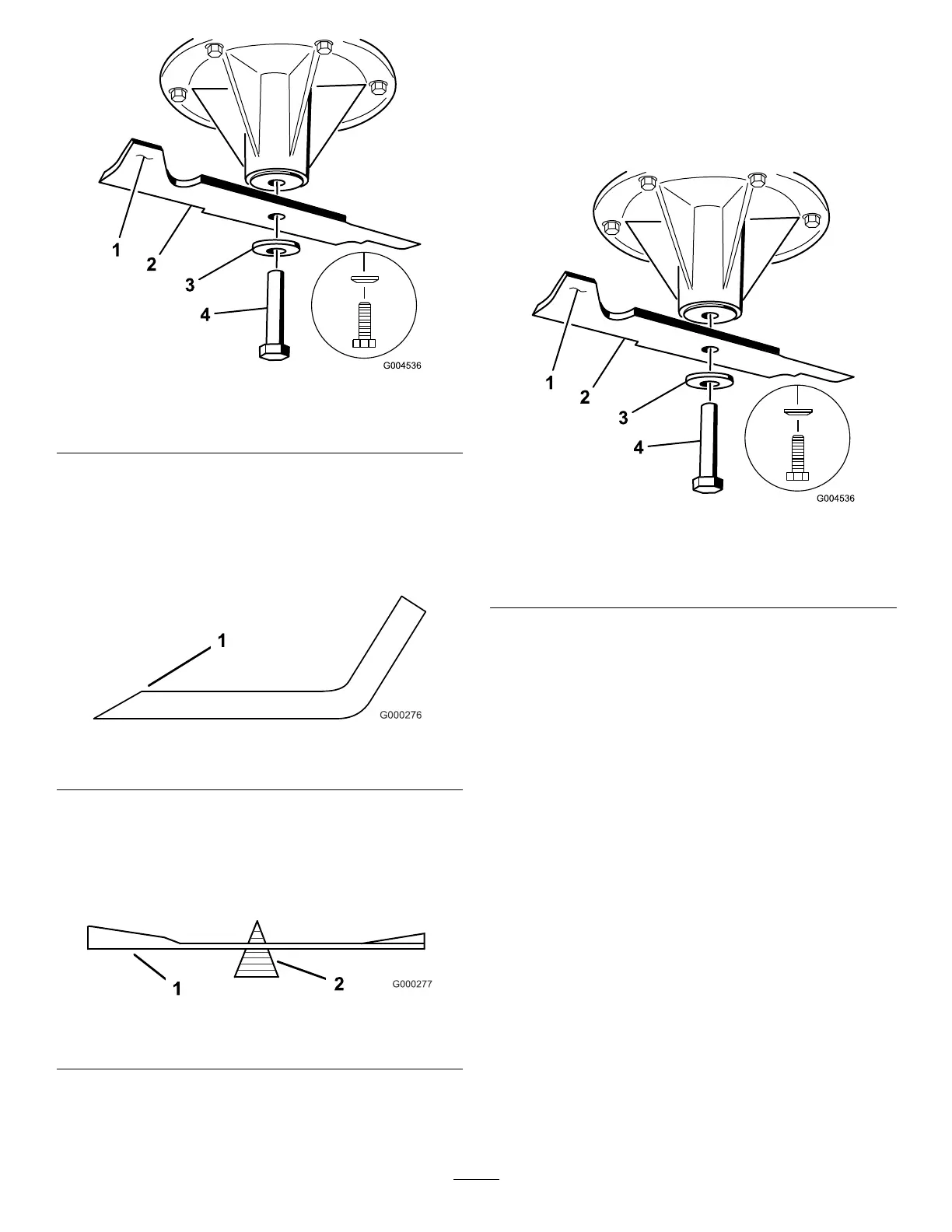

Figure82

1.SailAreaofBlade3.Curvedwasher

2.Blade4.BladeBolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure83).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

Figure83

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure84).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure82).Repeatthisprocedure

untilthebladeisbalanced.

Figure84

1.Blade2.Balancer

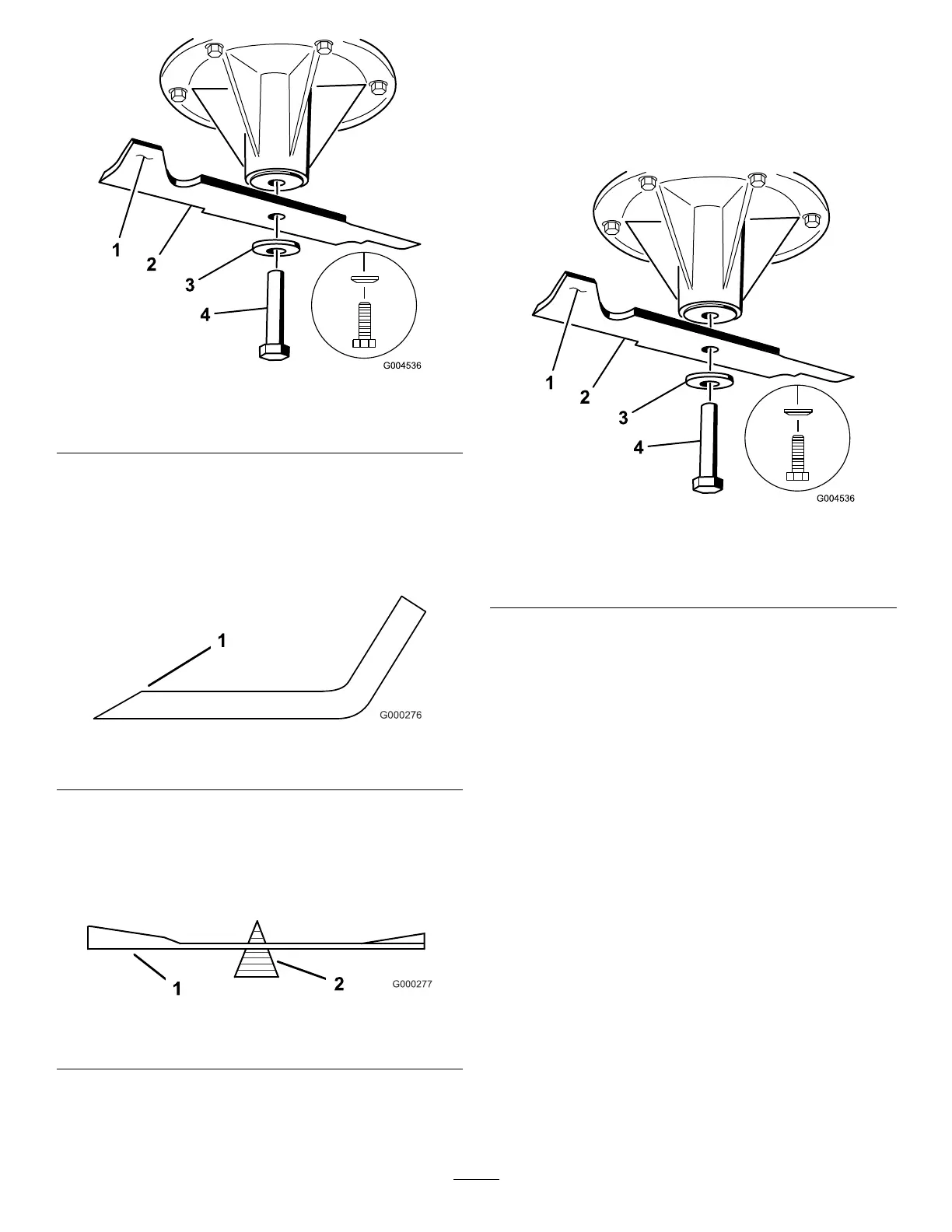

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure85).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladebolt.Thespringdisk

conemustbeinstalledtowardthebolthead(

Figure85).

Torquethebladeboltto85-110ft-lb(115-150N-m).

Figure85

1.SailAreaofBlade

4.BladeBolt

2.Blade

5.ConeT owardsBoltHead

3.SpringDisk

CorrectingtheMowerQuality

ofCut

Ifonedeckbladecutslowerthantheother,correctasfollows.

Note:Tireairpressureiscriticalintheseprocedures.Make

surethereartireshavecorrectpressure.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.Disconnectthesparkplugwire(s)fromthe

sparkplug(s).

3.Adjustthetirepressureinthereartiresto12-14psi

(83-97kPa).

4.Checkthatthebladesandspindleshaftsarenotbent.

RefertoCheckingforBentBlades.

5.Settheheight-of-cuttothe3inch(7.6cm)position.

RefertoAdjustingtheHeight-Of-CutinOperation.

6.Performthestepsinthefollowingproceduresinorder.

CheckingtheMowerDeckSide-to-Side

Height

1.Adjustthereartirepressure.

54

Loading...

Loading...