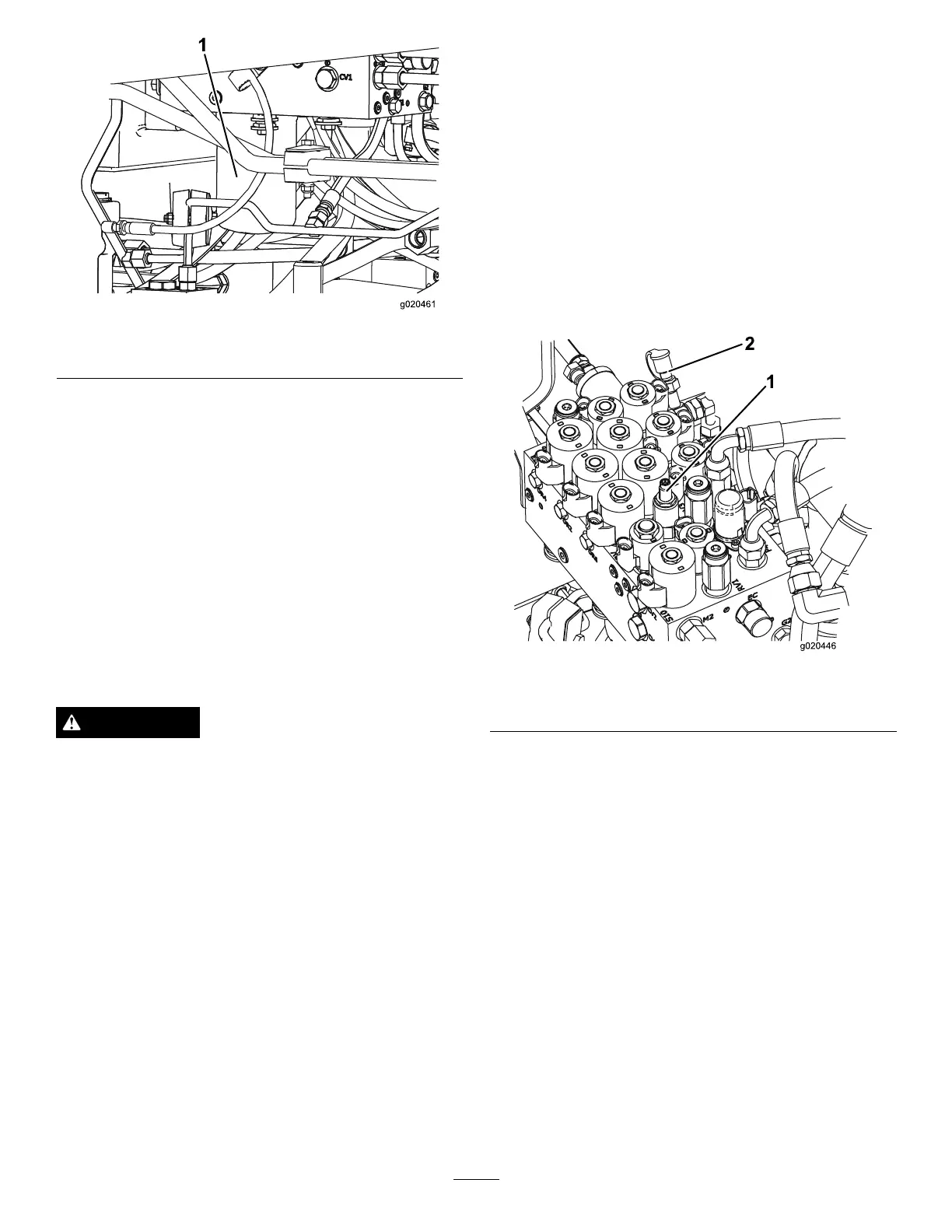

Figure75

1.Hydrauliclter

6.Oncethereservoirislled,starttheengineandletit

runatlowidleforapproximatelytwominutes.Activate

steeringandraise/lowercuttingunitsseveraltimesto

purgeairfromthesystem.Stoptheengineandcheck

forleaks.

CheckingtheHydraulicLines

andHoses

ServiceInterval:Every2years

Inspectthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,weather

deterioration,andchemicaldeterioration.Makeallnecessary

repairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

AdjustingtheCounterbalance

Pressure

Thecounterbalancetestport(Figure76)isusedtotest

thepressureinthecounterbalancecircuit.Recommended

counterbalancepressureis2241kPa(325psi).Toadjust

thecounterbalancepressure,loosenthelocknut,rotatethe

adjustingscrew(Figure76)clockwisetoincreasethepressure

orcounterclockwisetodecreasethepressureandtightenthe

locknut.Theenginemustberunning,thedeckloweredand

inoattocheckpressure.

Note:Thecastorwheelsofallthreecuttingunitsshould

remainonthegroundwhenadjustingthecounterbalanceand

withcounterbalanceapplied.

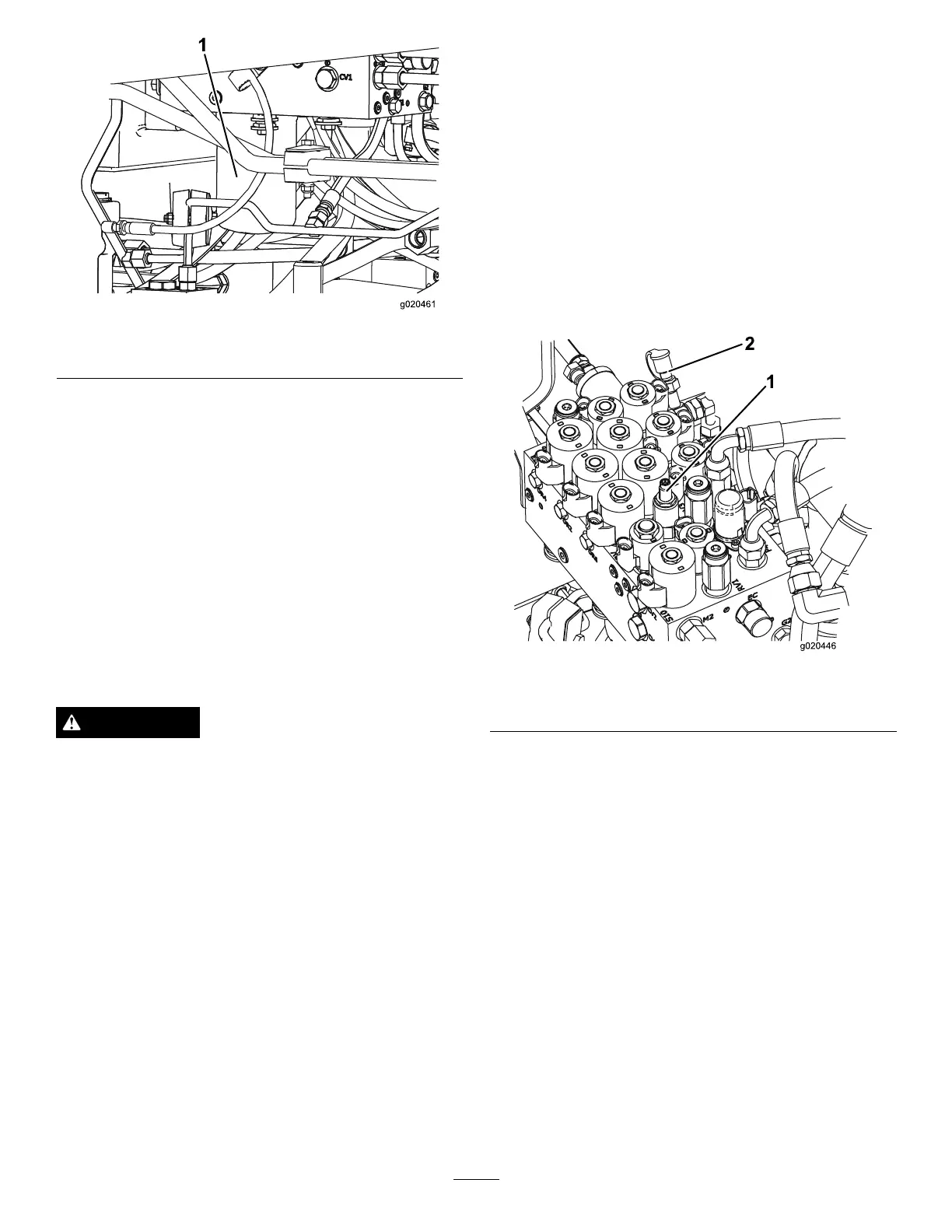

Figure76

1.Counterbalanceadjusting

screw

2.Counterbalancetestport

52

Loading...

Loading...