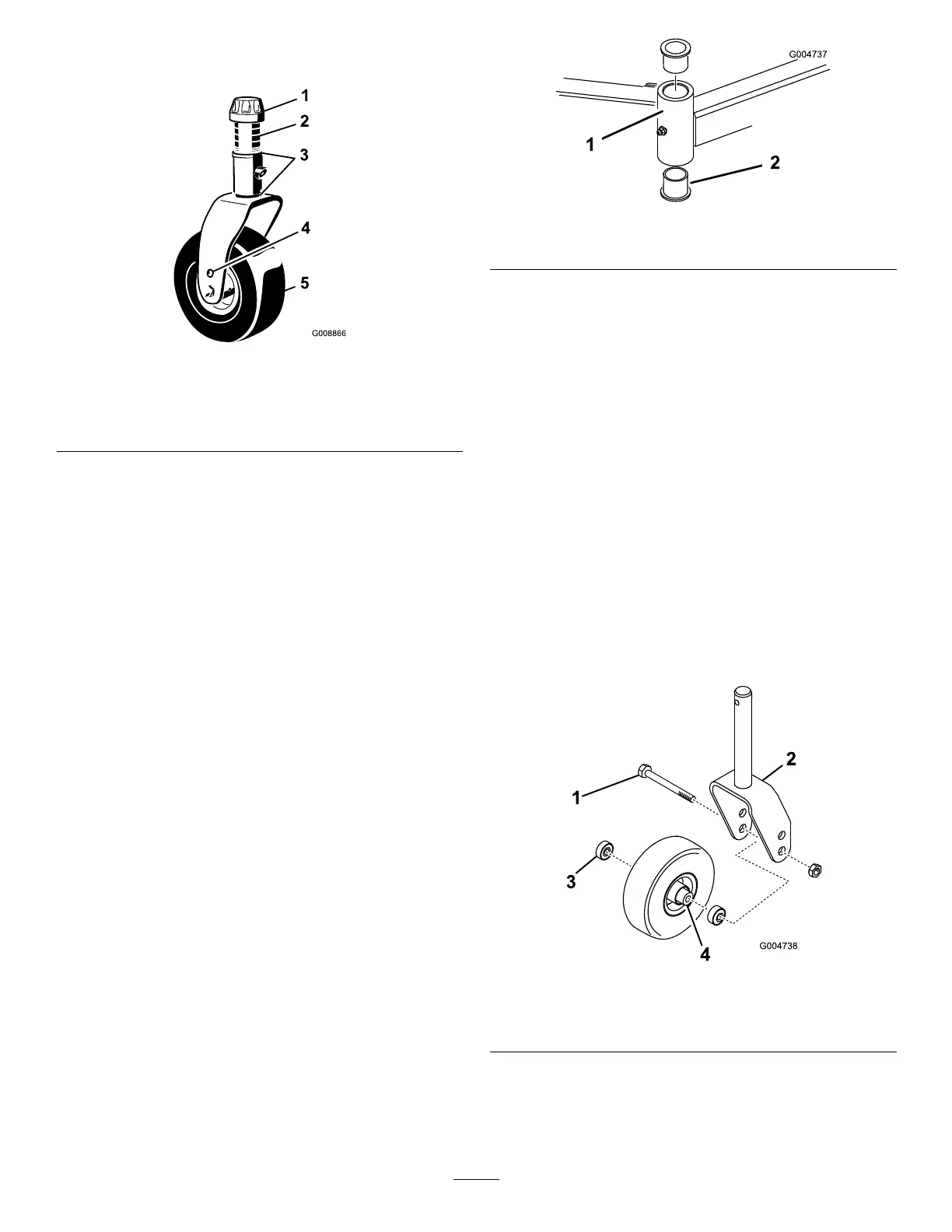

Repositiontheshims,asrequired,toraiseorlowerthe

castorwheeluntilthecuttingunithasthecorrectpitch.

Figure79

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Shims

2.Installthetensioningcap.

ServicingtheCastorArm

Bushings

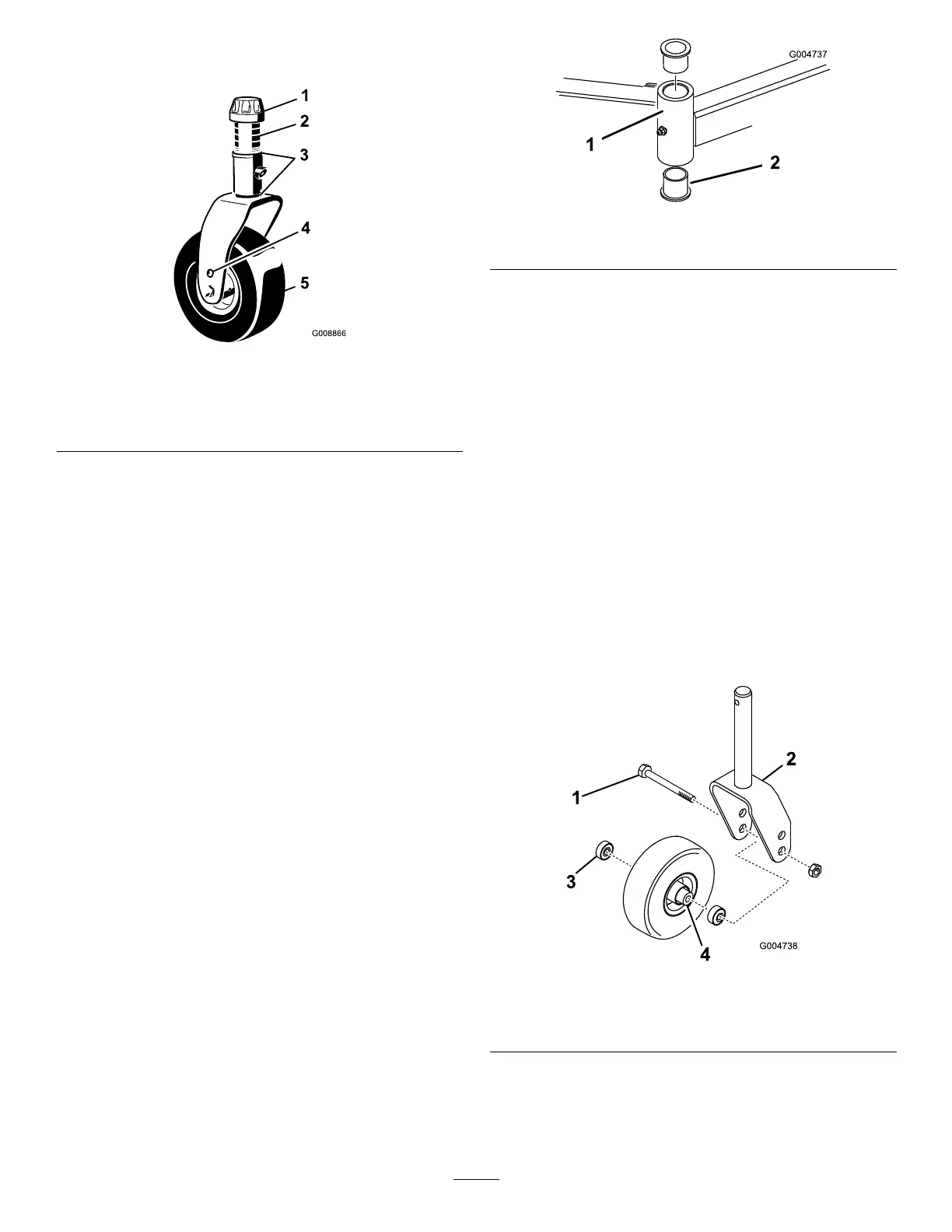

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(Figure80).Alsodrivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

Figure80

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitifit

isdamaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

ServiceInterval:Every800hours

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure81)

orthecastorpivotarm(Figure82).Graspthecastor

wheelandslidetheboltoutoftheforkorpivotarm.

Figure81

1.Castorbolt

3.Bearing

2.Castorfork

4.Bearingspacer

54

Loading...

Loading...