2.Withthebucketinstalledandangleddownward,

loweritintothegroundsothatthefrontofthe

tractionunitliftsoffthegroundafewcentimeters

(inches).

Note:Ifyoudonothaveabucket,raise

themachineandsupportitusingjackstands

ratedfortheweightofthemachine;referto

Specications(page18).

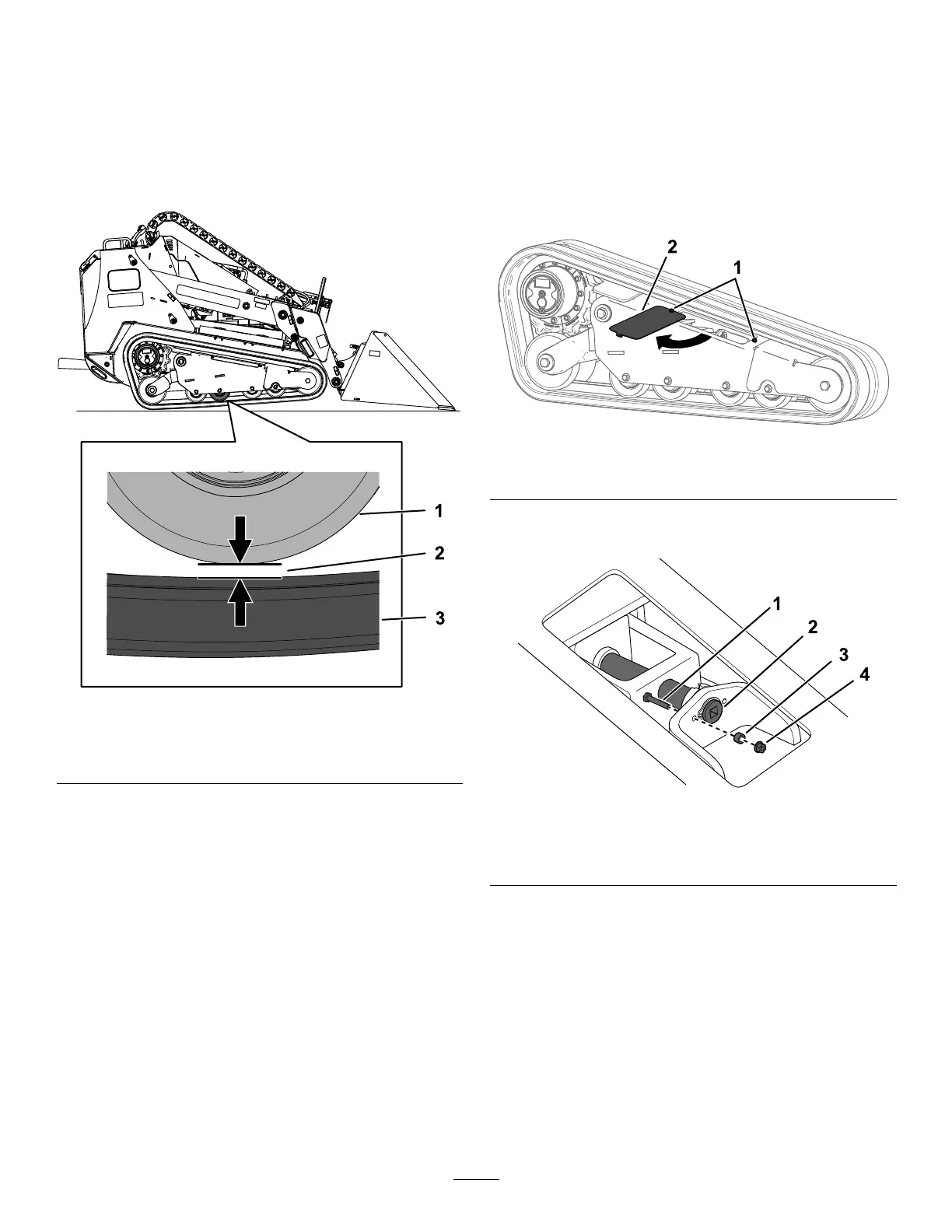

g263492

Figure68

1.Roadwheel3.Track

2.Gapis20mm(0.8inch).

3.Shutofftheengineandremovethekey.

4.Verifythatthegapbetweenthe2ndroadwheel

fromtherearandthetrackis20mm(0.8inch)

asshowninFigure68.Ifadjustmentisneeded,

proceedtoAdjustingtheTrackT ension(page

44)

AdjustingtheTrackTension

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Placea15x15cm(6x6inch)blockunderthe

rearframeofthemachine,directlybehindthe

trackbeingtensioned.

3.Withthebucketinstalledandangleddownward,

loweritintothegroundsothatthefrontofthe

tractionunitliftsoffthegroundafewcentimeters

(inches)andthemachinetipsbackontothe

blockuntilthetrackiscompletelyofftheground.

Note:Ifyoudonothaveabucket,raise

themachineandsupportitusingjackstands

ratedfortheweightofthemachine;referto

Specications(page18).

4.Shutofftheengineandremovethekey.

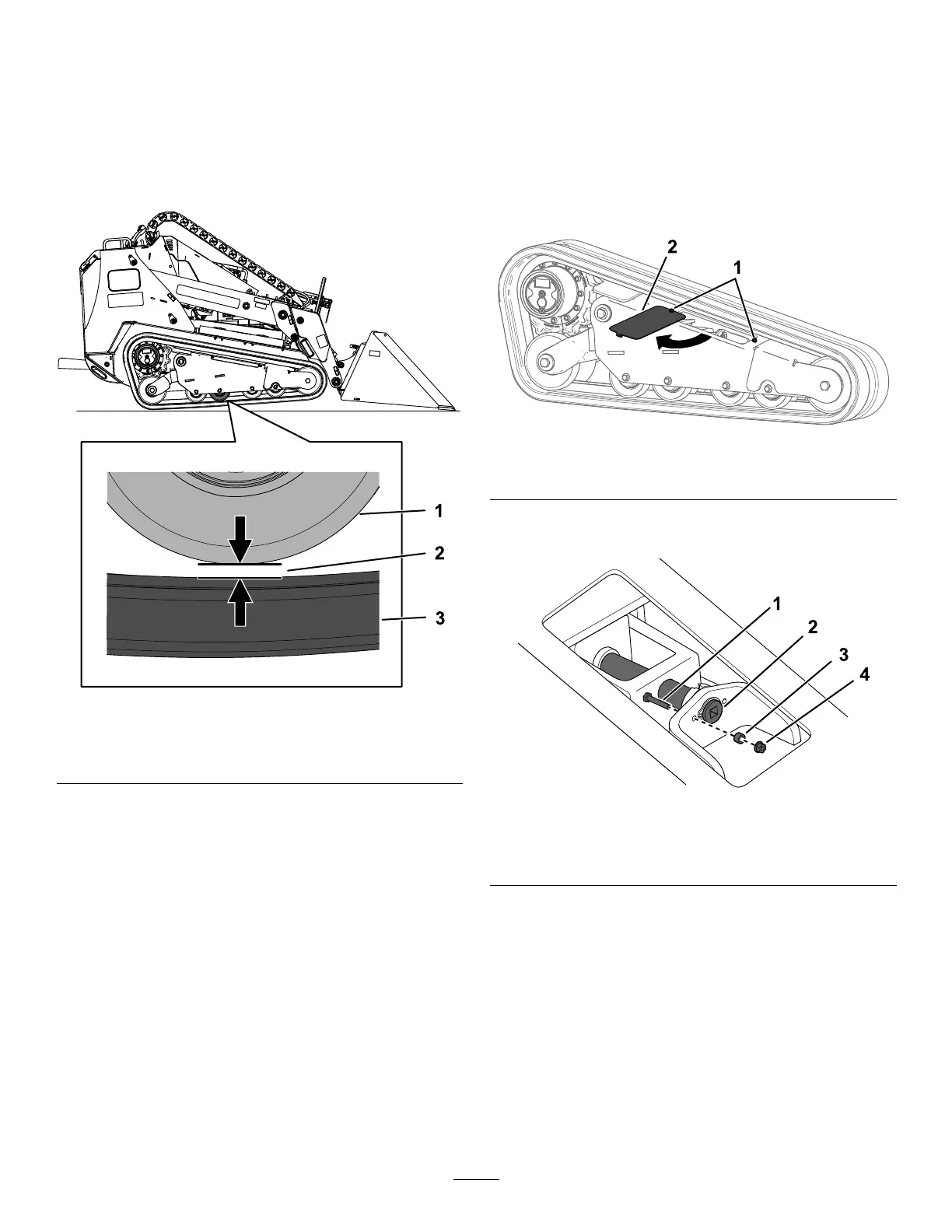

5.Loosenthe2boltsandrotatetheaccesscover

open(Figure69).

g262055

Figure69

1.Bolt2.Accesscover

6.Removethelockingbolt,spacer,andnut(Figure

70).

g262056

Figure70

1.Lockingbolt

3.Spacer

2.Tensioningscrew4.Nut

7.Usinga1/2inchdriveratchet,turnthetensioning

screwuntilthegapbetweentheroadwheeland

trackis20mm(0.79inch)asshowninFigure

68.

Note:Turningthescrewcounter-clockwise

tightensthetrack;turningthescrewclockwise

loosensthetrack.

8.Alignthenotchinthetensionscrewtothe

nearestlocking-boltholeandsecurethescrew

withthelockingbolt,spacer,andnut(Figure70.

9.Repeattheprocedurefortheothertrackif

needed.

44

Loading...

Loading...