EM-36

ENGINE MECHANICAL - Timinn Belt

EM302

EM301

,

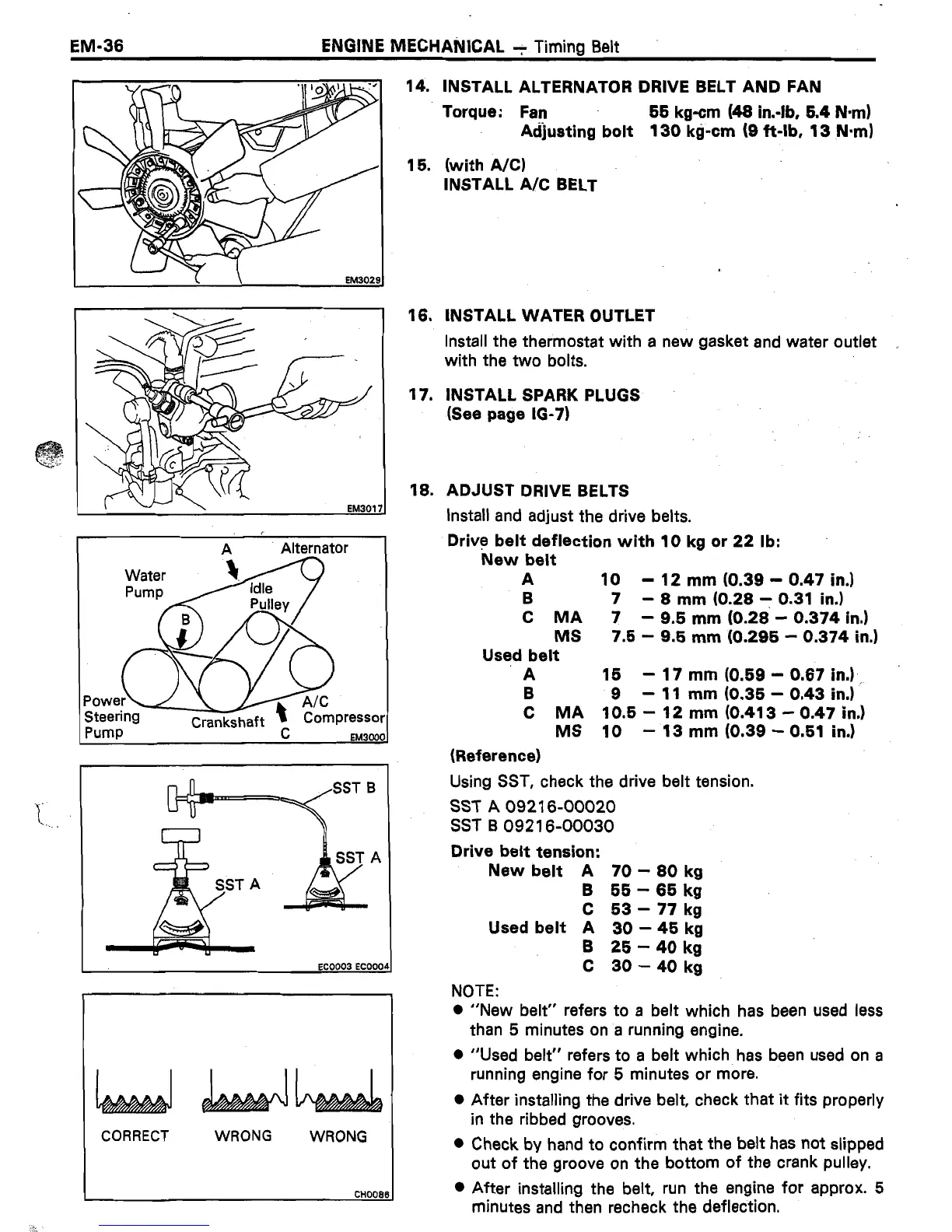

A

Alternator

1

EM3000

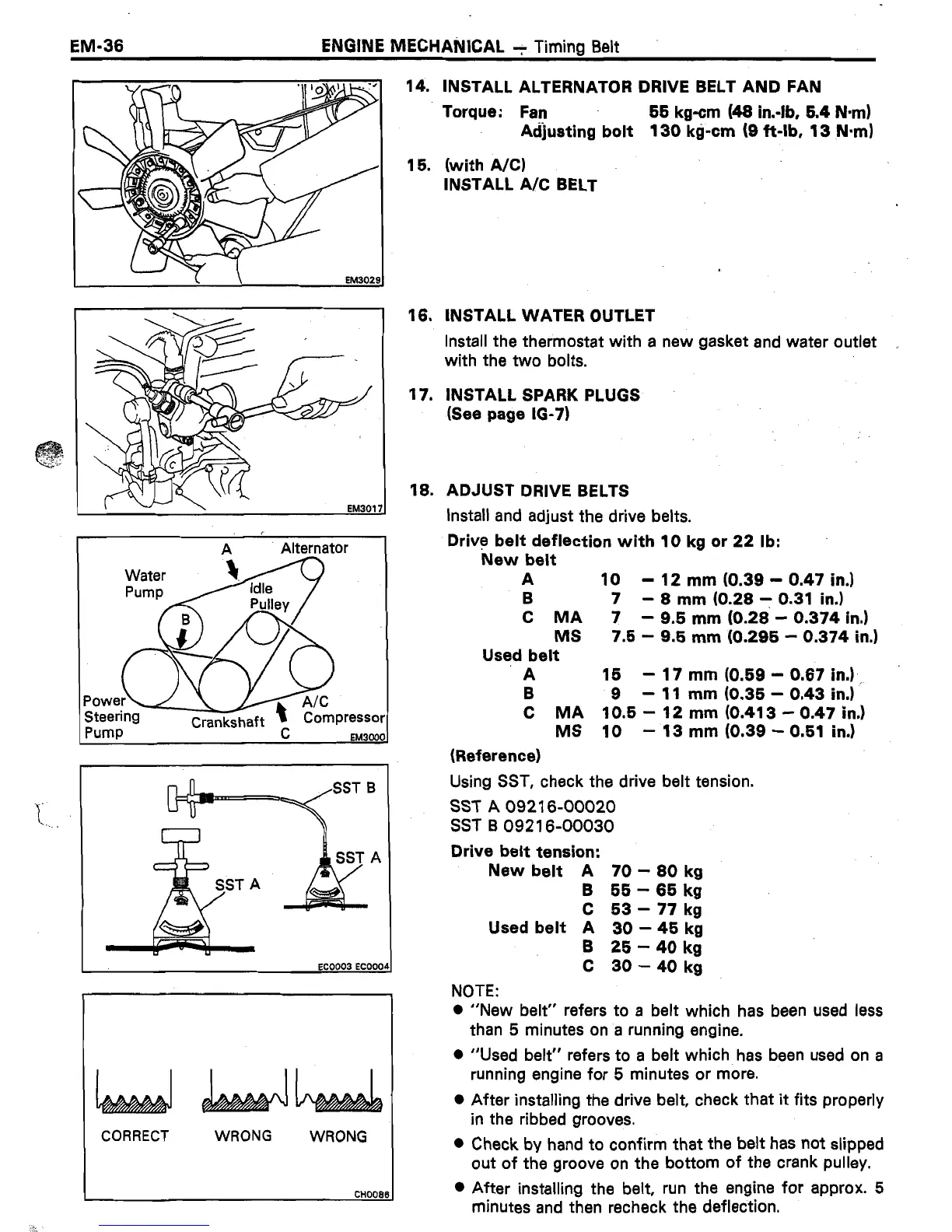

CORRECT WRONG

WRONG

14. INSTALL ALTERNATOR DRIVE BELT AND FAN

Torque: Fan 55 kg-cm (48 in.-lb, 6.4 N-m)

Adjusting bolt 130 kg-cm (9 ft-lb, 13 N*m)

15. (with A/C)

INSTALL A/C BELT

16. INSTALL WATER OUTLET

install the thermostat with a new gasket and water outlet

with the two bolts.

17. INSTALL SPARK PLUGS

(See page 10-7)

16. ADJUST DRIVE BELTS

Install and adjust the drive belts.

Drive belt deflection with 10 kg or 22 lb:

New belt

A 10 - 12 mm IO.39 - 0.47 in.)

B 7 - 8 mm (0.28 7 0.31 in.)

C MA 7 - 9.5 mm (0.28 - 0.374 in.)

MS 7.5 - 9.5 mm (0.296 - 0.374 in.1

Used belt

A 15 - 17 mm (0.59 - 0.67 in.1 ,

B 9 - 11 mm (0.35 - 0.43 in.)

C MA 10.5 - 12 mm (0.413 - 0.47 in.)

MS 10 - 13 mm (0.39 - 0.51 in.)

(Reference)

Using SST, check the drive belt tension.

SST A 09216-00020

SST B 09216-00030

Drive belt tension:

New belt A 70 - 80 kg

B 65 - 65 kg

C 53 - 77 kg

Used belt A 30 - 45 kg

B 25 - 40 kg

C 30 - 40 kg

NOTE:

0 “New belt” refers to a belt which has been used less

than 5 minutes on a running engine.

0 “Used belt” refers to a belt which has been used on a

running engine for 5 minutes or more.

0 After installing the drive belt, check that it fits properly

in the ribbed grooves.

l

Check by hand to confirm that the belt has not slipped

out of the groove on the bottom of the crank pulley.

l

After installing the belt, run the engine for approx. 5

minutes and then recheck the deflection.

Loading...

Loading...