RT-SVD03G-EN 91

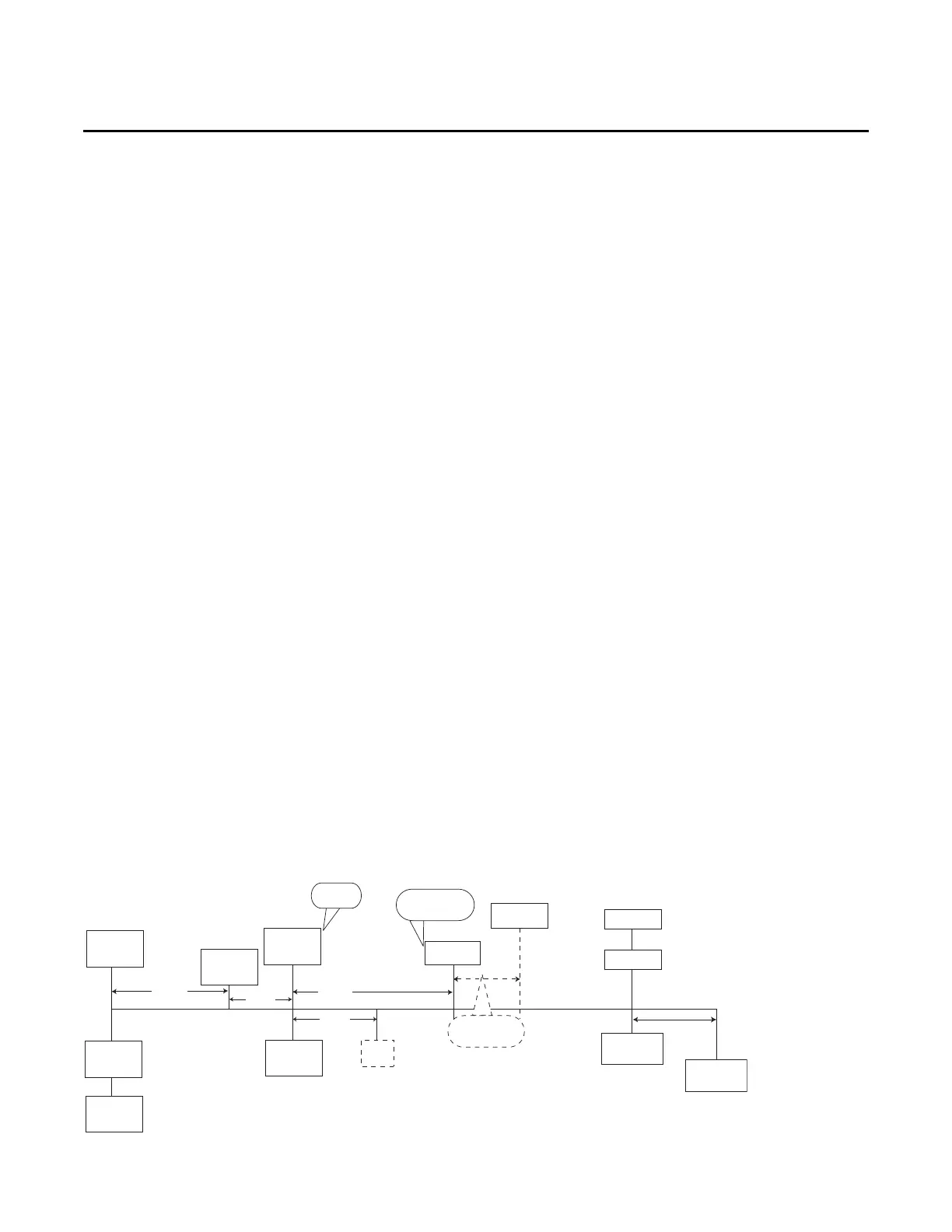

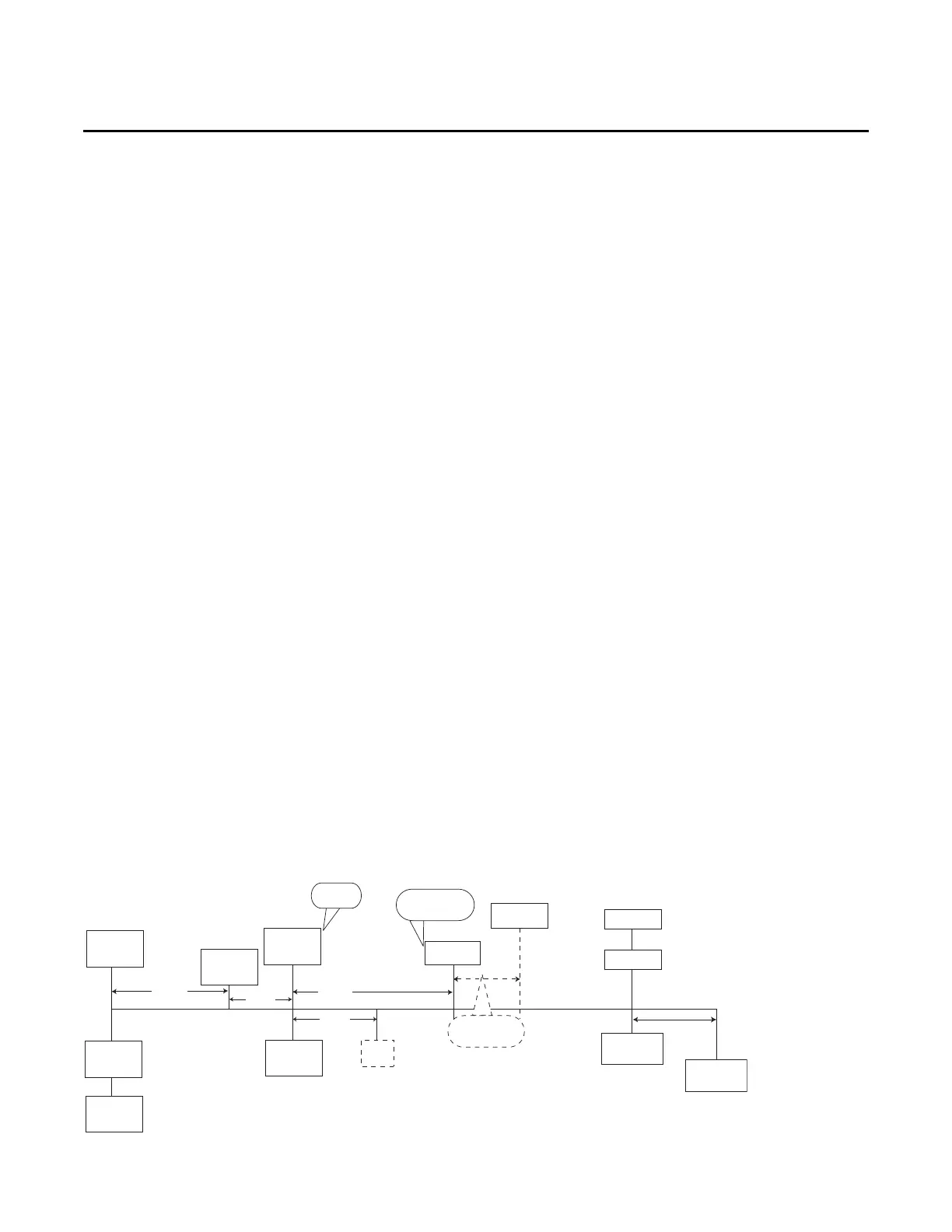

ReliaTel Hot Surface Ignition Control (12.5 - 50 Ton 1 Stage, 2 Stage, and Modulating Gas Heat)

Sequence of Operations (1 and 2 heat units)

The 12½ through 50 ton packaged units use a drum and tube heat exchanger with a negative

pressure gas valve and hot surface ignition. This design is the same as was used with the UCP micro

controls, but the control circuitry for ignitions has changed to take advantage of ReliaTel MODBUS

communications.

When the system switch is set to the "Heat" position and the zone temperature falls below the

heating setpoint, a heat cycle is initiated when the RTRM communicates ignition information to the

ignition module (IGN).

The IGN runs a self-check (including verification that the gas valve is de-energize). IGN checks the

high-limit switches (TC01 & TCO2) for normally closed contacts. With 115 vac supplied to the

ignition module (IGN), the hot surface ignitor probe (IP) is preheated for approximately 45 seconds.

The gas valve (GV) is energized for approximately 7 seconds for trial ignition to ignite the burner.

Once the burner is ignited, the hot surface ignition probe (IP) is de-energized by the ignition module

and then functions as the flame sensor. The unit initially fires on high heat, but after approximately

60 seconds, if no additional heating is required, the ignition module will drop back to low heat.

When the fan selection switch is set to the "AUTO" position, the RTRM energizes the indoor fan relay

(F) approximately 45 seconds after initiating the heating cycle to start the indoor fan motor (IDM).

If the burner fails to ignite, the ignition module will attempt two more ignition cycles before locking

out. The green LED will indicate a lockout by two fast flashes. An ignition lockout can be reset by:

4. Opening for 3 seconds and closing the main power disconnect switch,

5. By switching the "Mode" switch on the zone sensor to "OFF" and then to the desired position, or

6. Allowing the ignition control module to reset automatically after one hour.

If the burner trips due to a high temperature limit, the unit will shut down and initiate a four flash

diagnostic. After the limit cools down and closes, the burner will again restart. There is no limit to

the number of high limit trips that can occur.

When the RTRM is communicating with the ignition module (IGN), the MODBUS voltage can be

measured at the 3J5 plug, pins 3 (negative) and 4 (positive). The voltage will be flashing at

approximately 10.7 to 9.6 vdc at a rate of once every three seconds. If the 3J5 plug is disconnected,

the measured voltage at pins 3 and 4 on the RTRM will be approximately 10.5 to 11.2 vdc and will

be flashing. Flame current measurements can also be made at two pins on the ignition module

labeled "FLAME CHECK" located at the bottom of the module. Flame current can be measured with

a DC voltmeter. One volt dc equals one microamp of flame current (1vdc = 1mA).

27.5 - 50 ton "high heat" units use two drum and tube heat exchangers. Two ignition controls work

in tandem to provide heat as required.

Figure 55. ReliaTel Hot Surface Ignition Control Sequence of Operation

1st Stage Call

for Heat

Ignitor

Starts Heating

Combustion

Fan On

60 sec.

Start Trial

for Ignition

1st Stage

Heat On

Start 45 sec

timing for

ID fan

ID fan

starts

Heater goes

to low fire

Heater goes

to 2nd stage

Heating Call

Terminates

Combustion

Fan Off

ID Fan

Continues to

Run for 60 sec.

Indoor

Fan

Shuts Off

If a Call for 2nd

Stage, Heater

Stays on High Fire

Fires on

High Heat

Time will vary

depending on call

for 2nd stage

45 sec.

7 sec.

45 sec.

1 min.

Loading...

Loading...