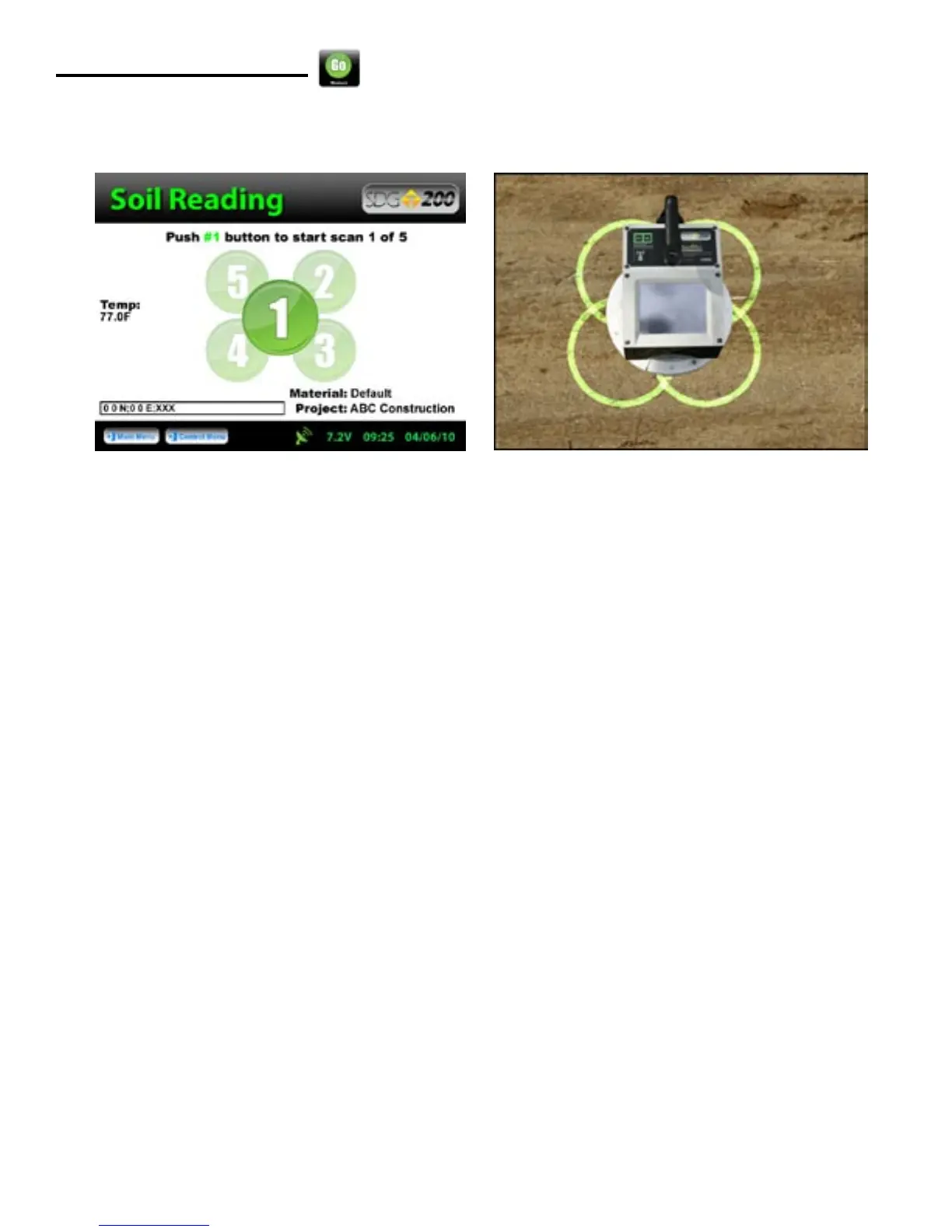

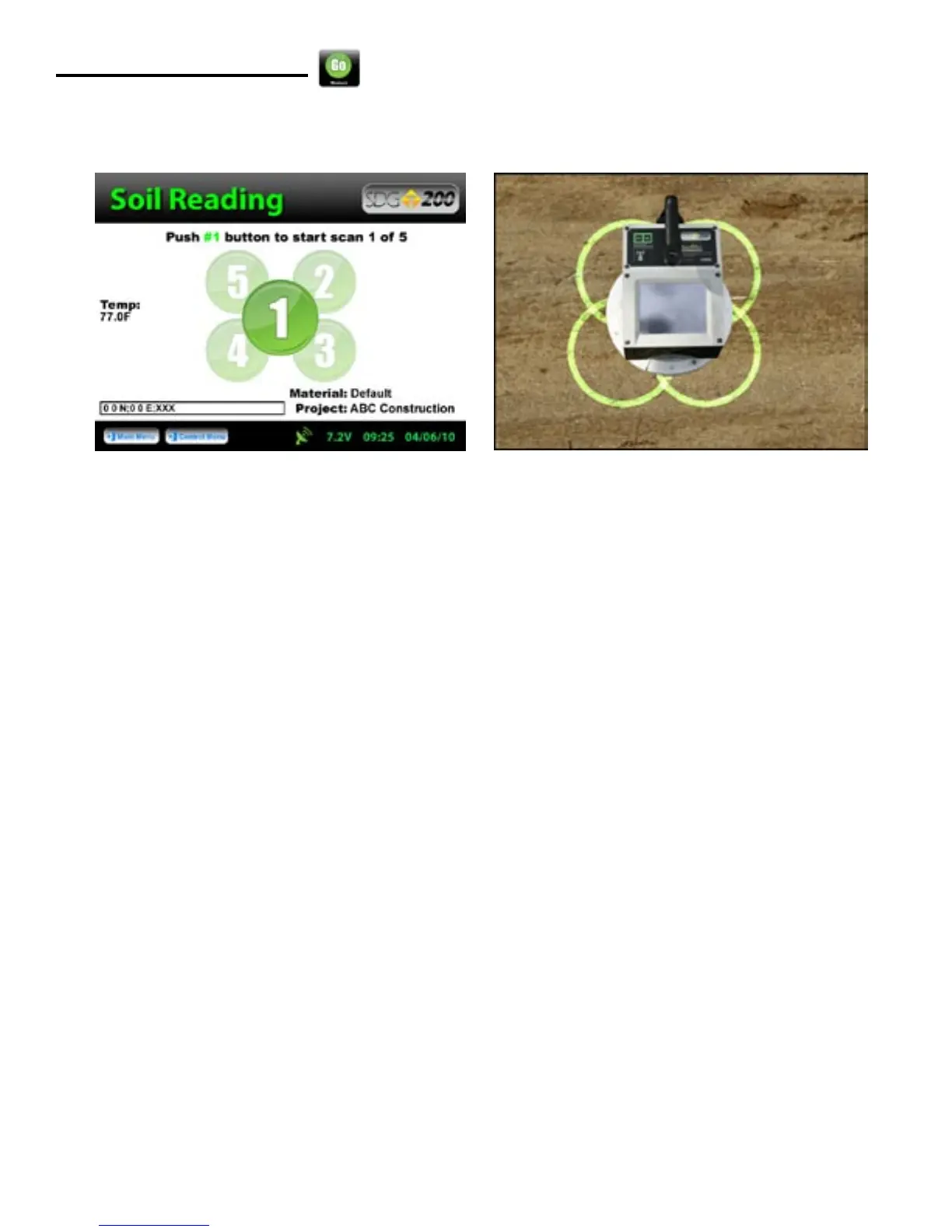

A complete test consists of five individual measurements taken in a “cloverleaf” pattern at the test location.

Each of the five measurements takes about 10 seconds. The SDG 200 is placed in position 1 for the first

measurement and moved clockwise around position 1 as indicated in the illustration above. Upon completion

of each reading, the SDG 200 will prompt the operator to move to the next location.

While the SDG 200 unit stands off from the soil, surface condition is still important. It is necessary for the soil

surface to be free from any loose and disturbed material, stones, large air pockets or ‘divots’ and other debris.

It is also important that the soil surface be smooth. If it is not, smooth out the surface or move the unit to a

location where the surface is smoother. The SDG 200 should not rock side-to-side when placed in a location to

take a measurement; if it does, move to a new location or remove the obstacle that is causing the rocking being

careful to not measure on top of any ‘divot’ left by removal of the object.

Large metal objects should not be within three feet of the gauge or underneath the soil while taking

measurements. Measurements within ten feet of buried power lines should be avoided. When possible,

measurements taken with an SDG 200 near an edge or vertical obstruction should be taken at least three inches

from that edge.

When placing the SDG 200 at a location for a measurement, do not push down on the unit to ‘seat’ the

unit in place. Set the unit down on the surface and check to see if it rocks side-to-side.

Do not touch the SDG while it is taking a measurement.

Part 2: Running a Test

Measurement Pattern

Surface Preparation

24

Loading...

Loading...