S

S

t

t

a

a

t

t

T

T

e

e

s

s

t

t

Erratic readings or readings that seem to fluctuate may indicate

a problem with the gauge. In the event the readings are

“suspect” the Stat Test may be executed to validate the normal

operation of the gauge.

A Stat Test consists of twenty 1-minute counts. Although other

count times are available (4, 8 and 16 minutes) they are not

recommended, since the temperature correction process is not

utilized during a stat test. Long count times (causing the stat test

to run overnight) could result in the gauge undergoing

temperature changes. It is very important that the ambient

temperature remain the same during the stat test. The longer

count times, however, can be used to check long-term gauge

operation.

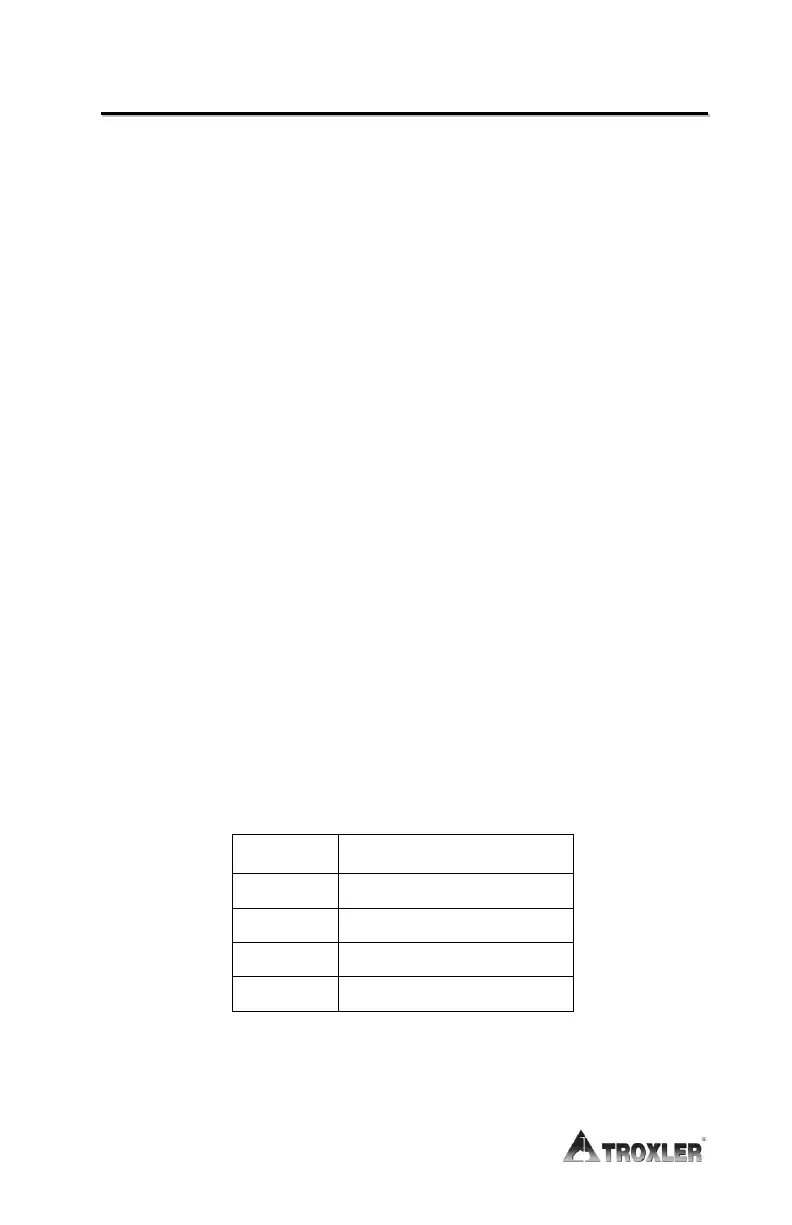

After the 20 counts, the gauge calculates the standard deviation.

This standard deviation is compared to a theoretical standard

deviation value. Ideally this ratio should be one. However, the

3241 prescale (or divide) for one minute counts is 4. This results

in an ideal ratio of (0.5). The acceptable limits for the ratio are

from (0.35) to (0.71). The gauge is considered to be unstable if

the ratio is outside these limits. The table below gives the limits

for other count times.

Ratio Table

Table 2. Range of Standard Deviation Ratios

Loading...

Loading...