Revision C – January 2023

CDS2000 Page | 20

The Power Always On function in essence renders the power button irrelevant as the system will

power on as soon as input power is supplied, and the power button will not turn the unit off.

The Intermittent Temp Tolerance function is a programmable timer that specifies a time period

during which a temperature fault is allowed to exist without disabling the delivery pump.

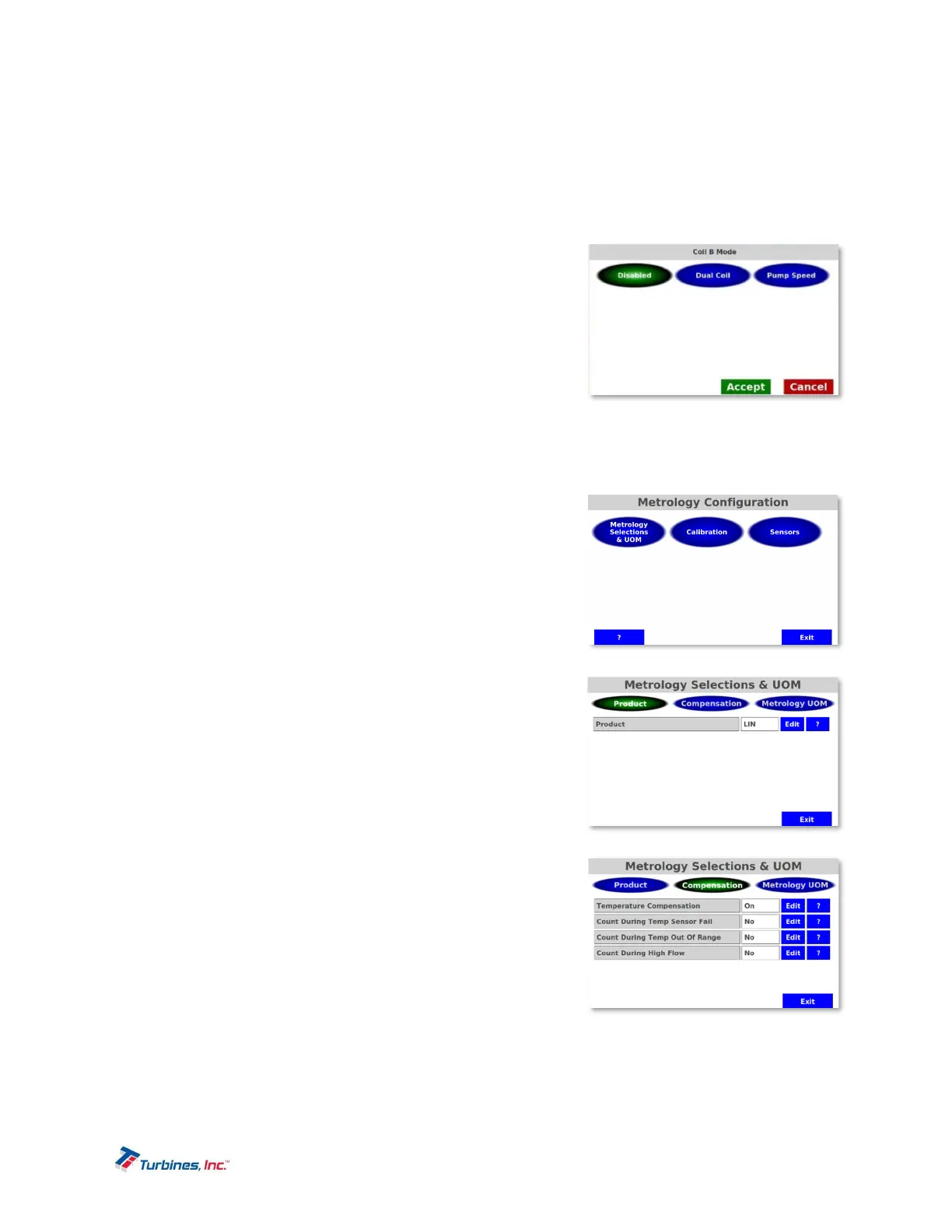

The Coil B Mode function allows selecting the function of the 2

nd

coil input.

o Selecting Disabled will turn off the 2

nd

coil input.

o Selecting Dual Coil engages additional signal

processing logic to capture input data from two

sources and logic is activated to detect reverse

flow along with missing or extra pulses.

o Selecting Pump Speed will use the 2

nd

coil input

to display pump speed. It is assumed sensing is

provided by a 24-tooth direct driven gear and non-

amplified magnetic pickup, similar to what is used

with the flowmeter.

The Printer Checking function enables handshaking between the printer and the CDS2000.

Depending upon the printer, the CDS2000 detects if the printer is online, out of paper and

enabled for delivery.

MetrologyConfiguration(UserPasswordProtected)

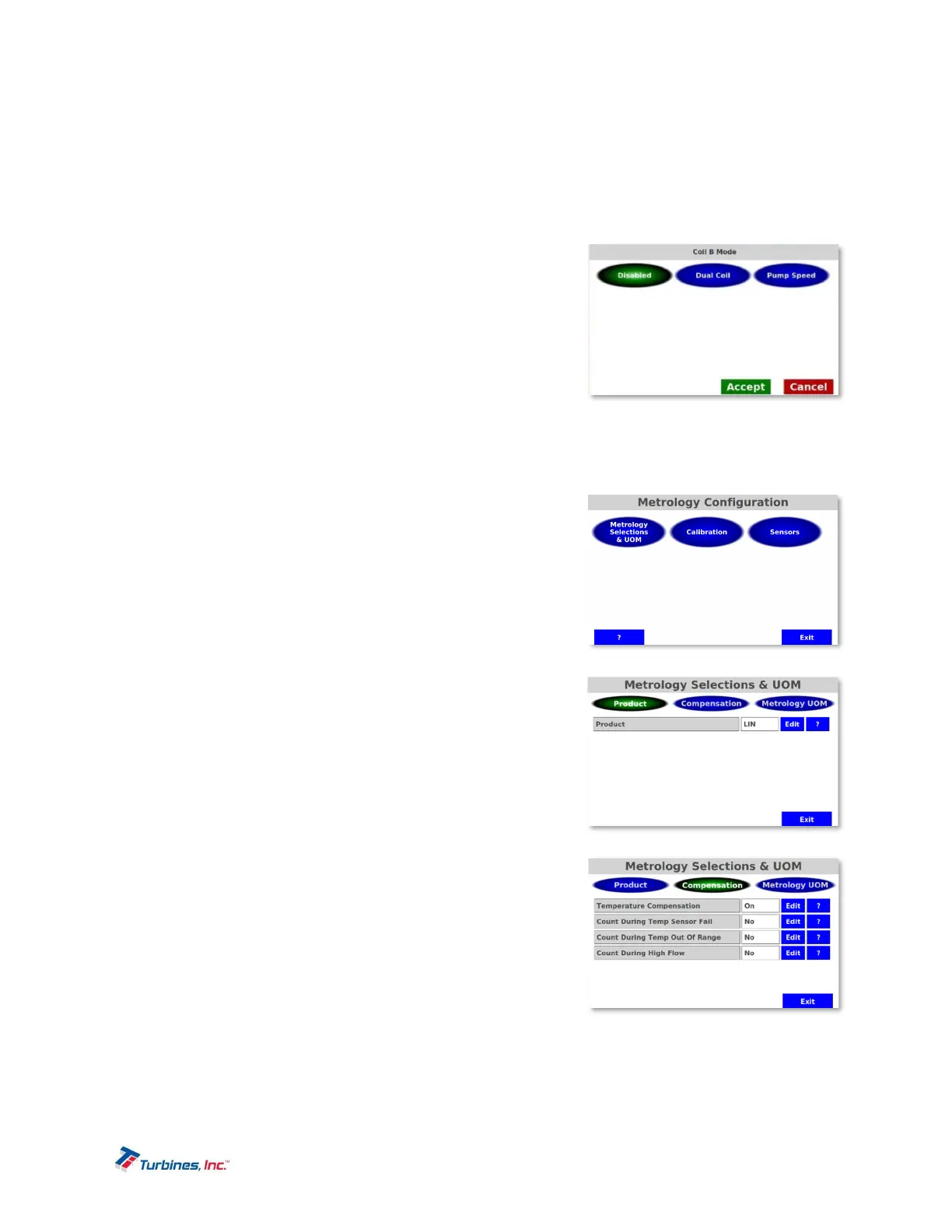

The Metrology Configuration menu provides the end user with the

option to adjust the “Metrology Selections & Units of Measure

(UOM)”, “Calibration”, or “Sensors” of the meter components

associated with the CDS2000.

MetrologyConfiguration–MetrologySelections

o The Product function selects the product to be

measured. Selection of the proper product is required

because the product selection contains configuration

information such as product density over temperature,

unit of measure equivalency information bar graph min

and max limits, etc. The standard products supported

are: LOX, LIN, LAR, LCO2, LN20, CCO2, MAPP, and

LPG. Additional products can be added. Consult the

factory for details.

o The Compensation function determines how temperature

information is utilized.

Temperature Compensation activates (ON) or

deactivates (OFF) the temperature compensator.

Simply stated, the compensator adds pulses to the

pulse total when the detected temperature is colder

than the product’s Normal Boiling Point (NBP) and

subtracts pulses when the product temperature is

warmer than NBP. The quantity of pulses added or

subtracted is determined by the temperature’s

departure from NBP.

Count During Temp Sensor Fail allows the programmer to select whether the system will

count during a RTD product sensor failure. Selecting “NO” disables the totalizer during a

temperature alarm and prevents registration of vapor. No counting or totalization will occur

during a product temp sensor failure when “NO” is programmed for Count During Temp

Sensor Fail. Selecting “YES” permits the totalizer to count at the product’s default warmest

Loading...

Loading...