Revision C – January 2023

CDS2000 Page | 27

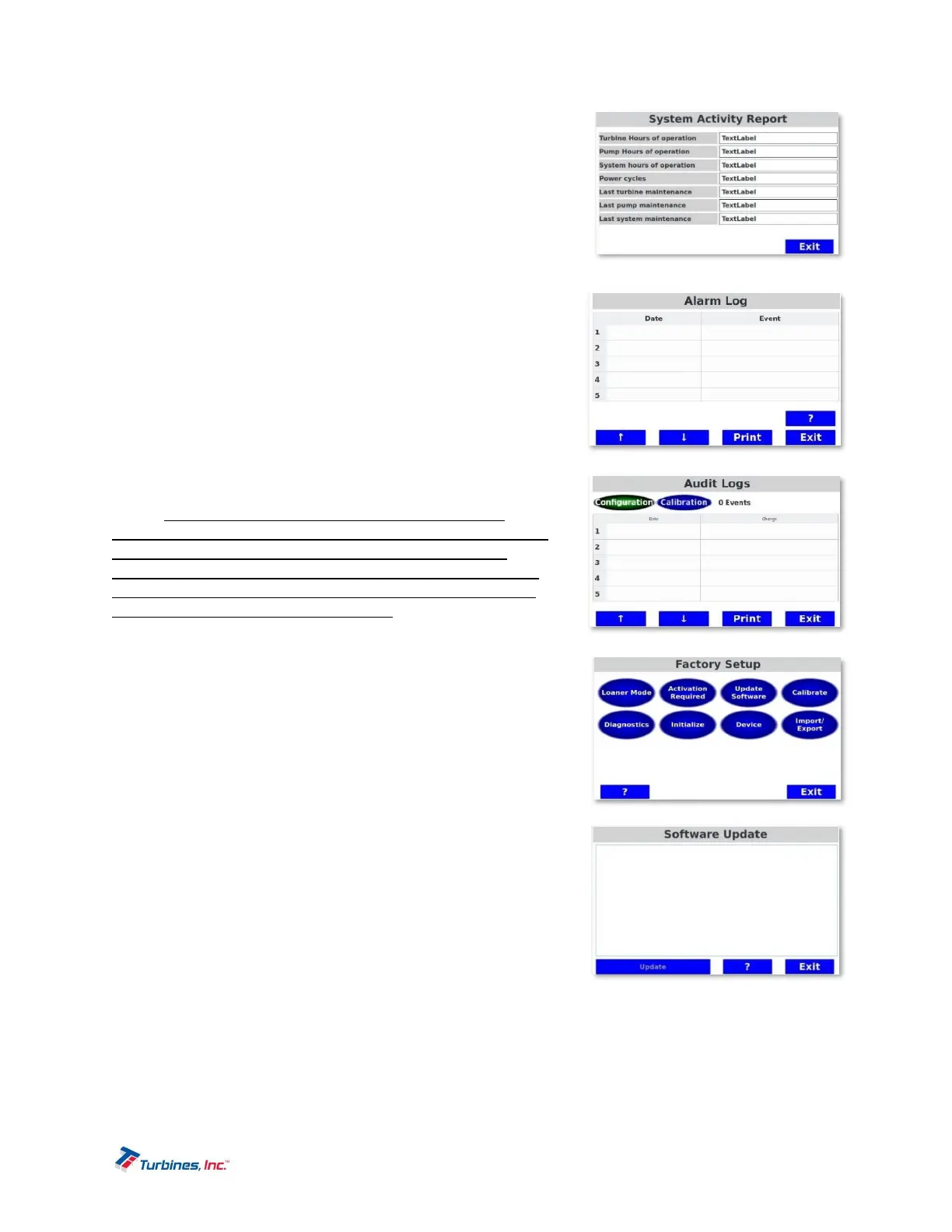

SystemActivity

These values are continuously updated by the system and can be

viewed in this menu.

Turbine Hours of Operation

Pump Hours of Operation

System Hours of Operation

Power cycles

Last turbine maintenance

Last system maintenance

ViewAlarmLog

Records all alarms that occur within the system. Alarms are

recorded in the order of occurrence beginning with the most

recent.

ViewAuditLogs

The Audit Trail contains a log of both the configuration and

calibration events that have occurred within the system. Events

are recorded in the order of occurrence beginning with the most

recent. Please note: the audit trail can be accessed while

powering on the unit via the following process: While the unit is

powering ON, a red screen is visible followed by a screen

displaying the Turbines Inc. logo. With either screen showing,

depress and hold BOTH middle softkeys for approximately 15

seconds until the Audit Trail logs appear.

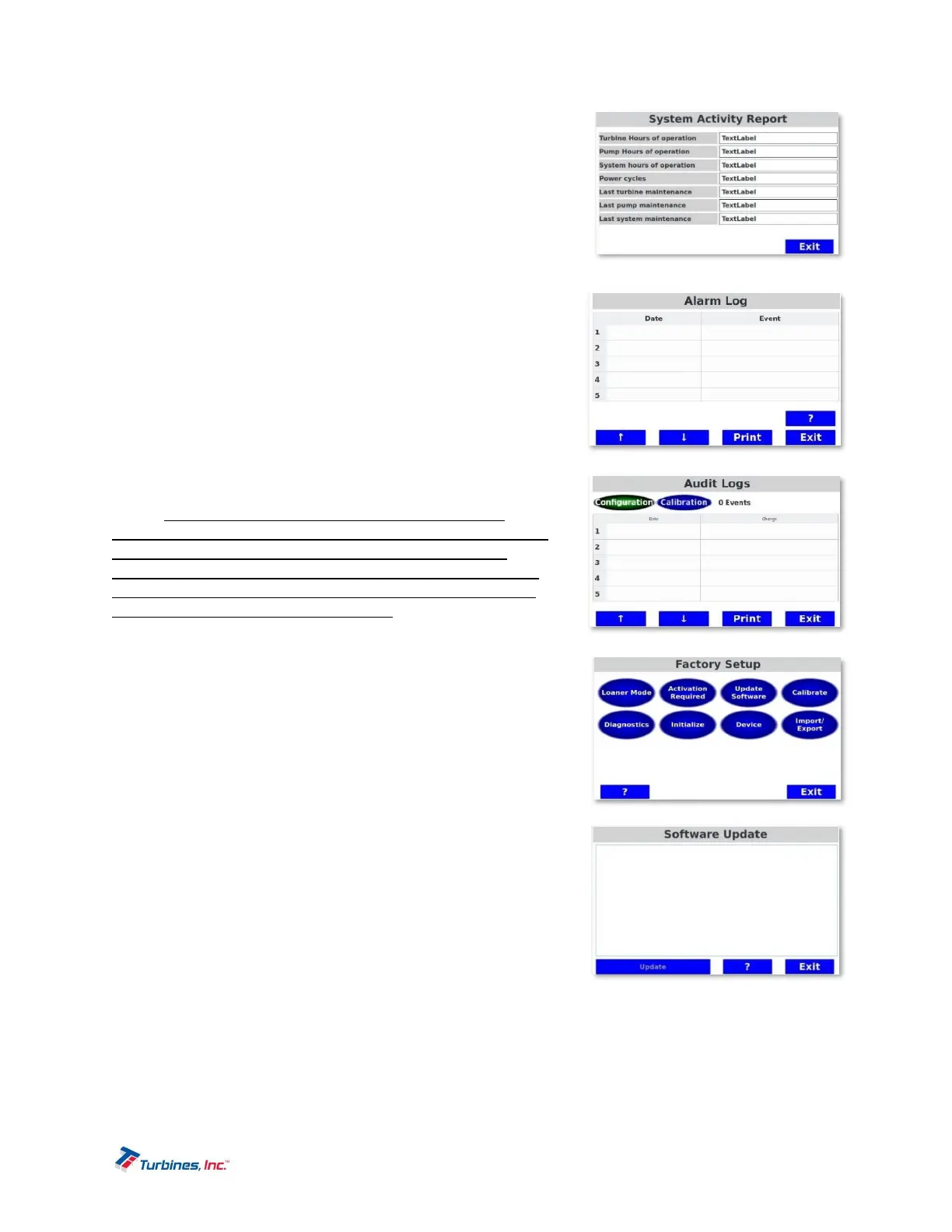

Factory(PrivilegedPasswordProtected)

The Factory settings are only available to factory personnel. The

function capabilities under Factory Setup include the following:

LoanerMode

Configurations are used to determine if the CDS2000 is to disable

itself after a certain period of time. A password entered in the field

is available to extend the loaner period.

ActivationRequired

Activation required is used to determine if the CDS2000 must be

activated before being used. This allows stocking the unit by the

customer without consuming the warranty period. Activating the

unit automatically inserts the date of activation into the date of

manufacture for warranty purposes. If activation is required, an

activation code must be acquired from the factory.

SoftwareUpdates

Software updates require a Privileged Password and should be conducted by authorized personnel.

CalibrationSettings

Temperature Calibration leads the technician though a calibration procedure that sets the zero

and gain of the temp circuits. 100,1K and 10K RTD inputs, silicon diode and 4-20mA temperature

sensors inputs can be calibrated. Each sensor being used needs to be calibrated.

Loading...

Loading...