Revision C – January 2023

CDS2000 Page | 7

Optional pump control and protection based on pump discharge or differential pressure.

Built-in self-test system of diagnostics.

Comprehensive internal warning and error reporting system.

Pump and turbine maintenance timers.

Non-resettable “Grand” totalizer.

RS-232, USB and Bluetooth communications are available.

Level 3 Audit trail for all sealable meteorological parameters.

Password protected configuration and calibration parameters.

Overview

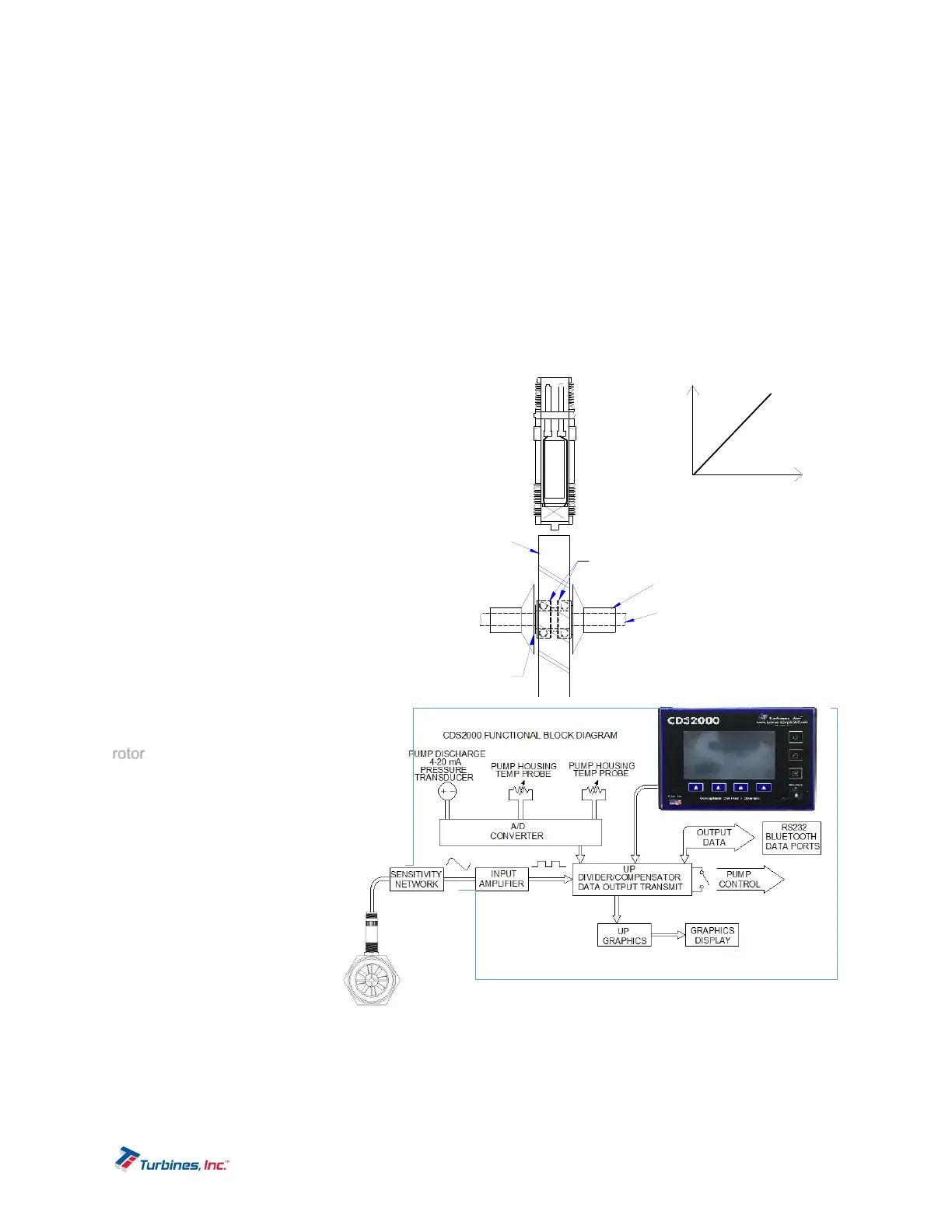

When introduced to flow the turbine flowmeter generates an AC sinewave signal within the pickup coil

located directly above the turbine’s rotor. The signal of the pickup coil is amplified, divided, corrected, and

displayed by the CDS2000. The displayed total

is corrected for temperature by sensing the

resistance of the RTD temperature probe.

Delivery information, consisting of 17 selectable

parameters, is transmitted via Bluetooth or

RS232 communications depending on which

data collection device or printer is selected.

Historical delivery data in internally captured

and can be offloaded via a built-in USB

interface. This unique integrated system

provides the end user a configurable, compact

total delivery system.

TheoryofOperation

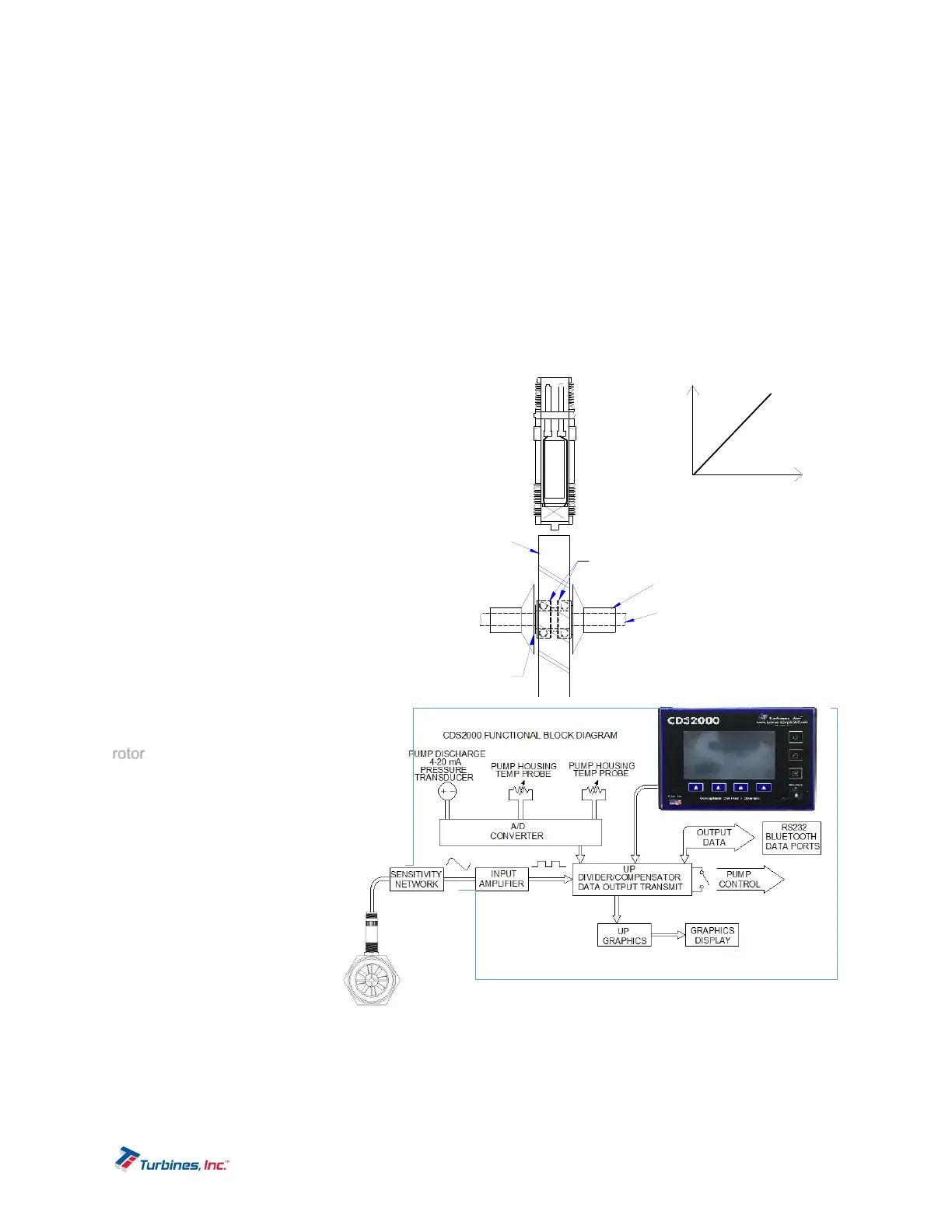

The TI turbine flowmeter is a velocity

measurement device that measures fluid

velocity and volume with one moving

component, the rotor. The

momentum of the flowing

fluid engages the low mass

rotor

resulting in the rotor

rotating at an angular

velocity that is proportional

to the fluid velocity. The

rotor’s rotation generates an

AC sinewave signal in the

pickup coil. TI turbine

flowmeters are linear

devices therefore the signal

output frequency is

proportional to the flowrate

within the designed flow

range. Another benefit of a

linear turbine meter is its K-

factor, the number of pulses

generated per unit volume (gallons, pounds etc.) is consistent over the entire flow range. The total

number of pulses generated is directly related to the total volume. The displayed total in the desired

engineering unit is acquired by dividing the total pulses by the K-factor. Because product density is

influenced by fluid temperature, volumetric flow meters require temperature to be measured and

SIGNAL AMPLITUDE

Q

0

MAX

FL OW

MI N

5000

mV pp

Bearings

Cone

Plat form

Ro t o

Sha ft

Co n e

Faraday - voltage induced from interruption of a magnetic

fie ld by p as s ag e o f a fe r r ou s ob jec t thr ou gh t he

fie ld is pr op or tio nal to v el oc ity of th e pas s in g objec t.

Loading...

Loading...