UES AG · Breuershofstr. 48 · 47807 Krefeld · Germany

Tel.: 0049-2151-72950 · Fax: 0049-2151-729578 · info@ues-ag.net · www.ues-ag.net

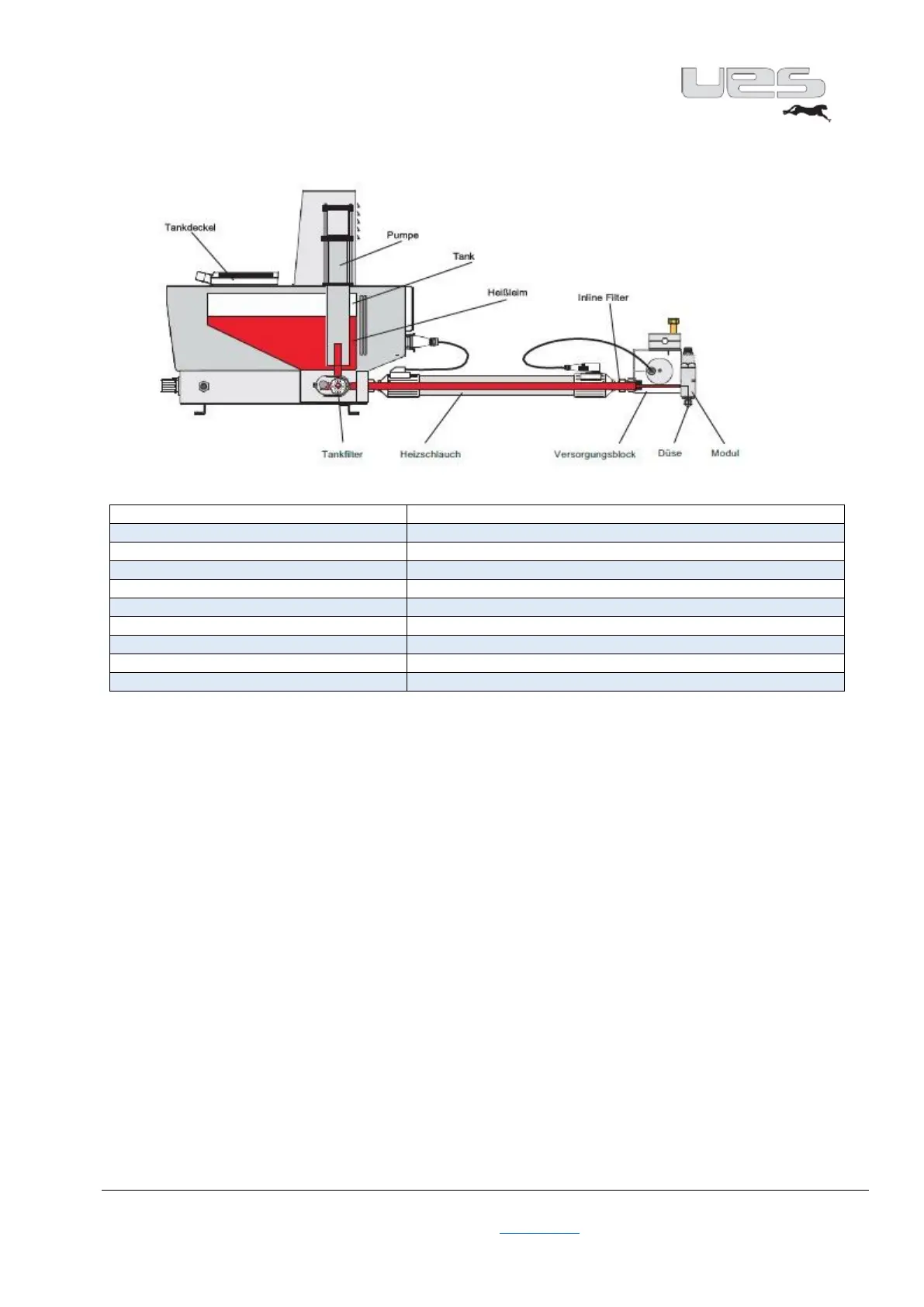

Example of a hot glue system

(Connecting parts are not supplied with the perfectMelt)

The fuel tank cap closes the tank. After filling, please use the fuel tank cap to close the tank of your

perfectMelt system.

The hot glue is melted in the tank. Your perfectMelt has two adjustable heating zones: the tank "t1" and

the manifold block "t2" (distribution block to connect the hot glue hoses).

The pump places the melted glue under pressure. UES-pumps have a translation ratio of 14:1. In other

words, at a set air pressure of 2 bar, there is a material pressure of 28 bar.

To prevent contamination in the hoses and application guns, the perfectMelt has a (tank) glue filter.

The hot glue hoses are connected to the glue dispenser. They are heated electrically and are connected

with the perfectMelt by a plug.

As an option, an in-line filter can be installed between the hose end and the gun.

The supply block is supplied with hot glue via the tube. It is also heated and is connected to the hose

electrically.

One or more modules are bolted onto the supply block. The modules open and close by air control (via a

solenoid valve).

For standard modules, screwable vents are necessary. Different nozzles are available for different

applications.

Loading...

Loading...