A. PREPARATION OF THE SITE

- The machine must be posed on a horizontal level.

- It is necessary to leave a free space of 5 cm all around the machine and not to block

the pulling of air placed on the top of the machine.

- Allow a power supply corresponding to the power of the machine, a water supply and

a drain of “worn water” (waste outlet).

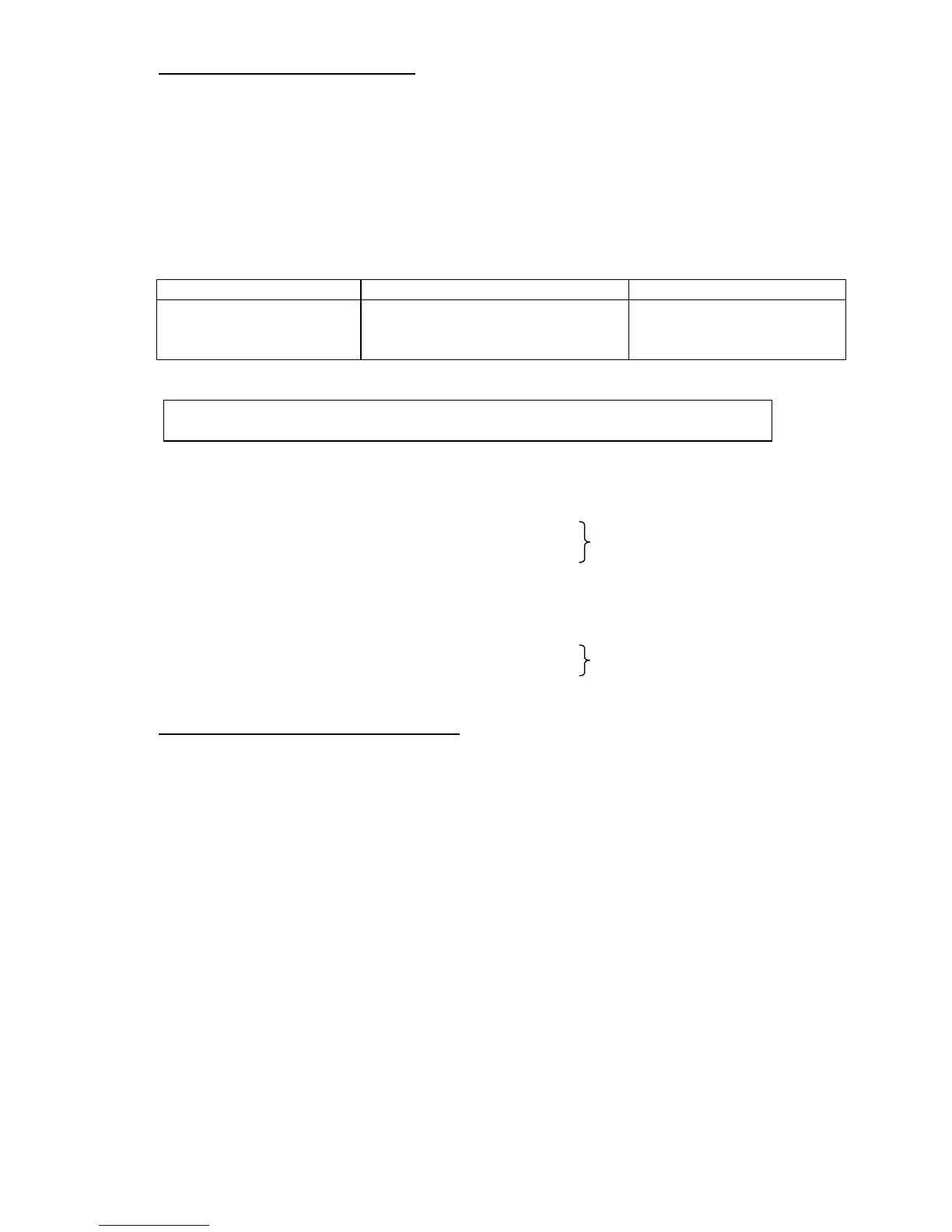

1. Power supply

Power to be installed according to the type of machine

Tension DUO SOLO

200 V mono 6 kW - 30 A 4.2 kW - 21.3 A

230 V mono - 400 V tri + N 8 kW - 35 A - 18 A 5.6 kW - 24.5 A - 8.2 A

240 V mono - 415 V tri + N 8.7 kW - 36 A - 12 A 6.1 kW - 25.5 A - 8.6 A

Allow a disconnecting switch and a plug near the machine

Ö EARTH CONNECTION IS MANDATORY

2. Water supply

- Pressure : 0 - 10 bar.

- Fitting: 3/8 gas female (male on the machine). Provided with the machine

- Pipe : internal diameter 8 mm minimum.

- Allow a stop valve.

3. Drain

- Fitting : 3/4 gas female (male on the machine). Provided with the machine

- Pipe : internal diameter 12 mm minimum.

B. PREPARATION OF THE MACHINE

The machine is delivered in a box and is screwed on a wooden pallet

1. Unpacking of the machine

- Cut the hooping with a shears

- Open the case and leave the box containing the accessories

- Unscrew the nuts fixing the machine at the pallet by inclining the case slightly

- Separate the cardboard from the pallet

- Pull off the machine of the pallet and put it on wood wedges.

- Pull off the screws and washers of transport

2. Installation of the machine

Position the machine on its final area, and put it level using the rubber discs if necessary.

B-1

Loading...

Loading...