B1 User Manual

© 2022 All rights reserved, Unitree Robotics 10

[1] Coprocessor Interface (Type-C)

[2] Main Processor Interface (Type-C)

The back cover of B1 also provides two interfaces, namely the main processor Type-C interface and the coprocessor

Type-C interface. The PC can be directly connected to the B1 core controller through these two interfaces. The main

processor interface and coprocessor interface are used for:

Firmware upgrade.

Real-time broadcast of hardware status information.

Troubleshooting. When B1 fails, users can check the status of B1 through these two interfaces and conduct

preliminary fault analysis and diagnosis.

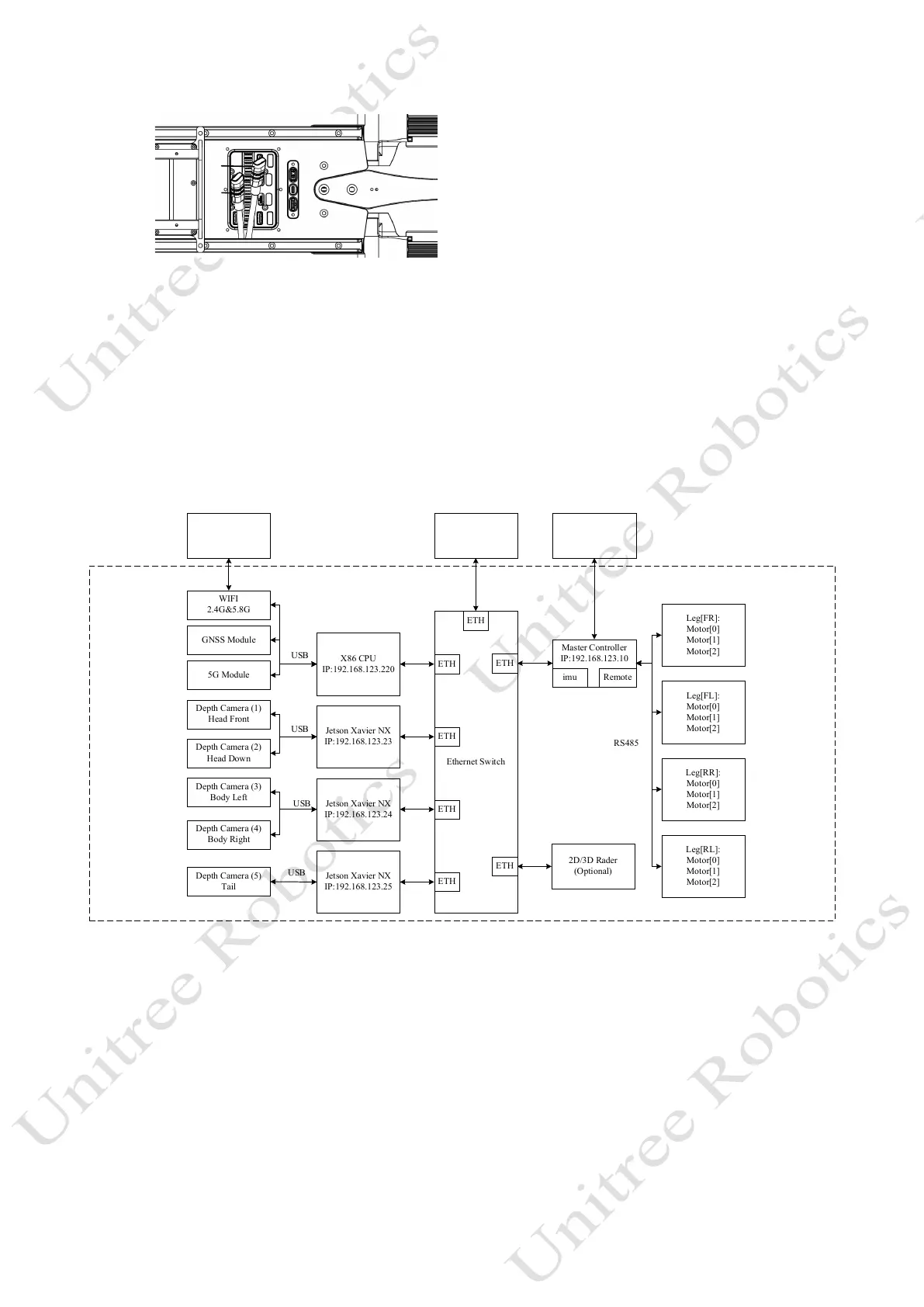

Network architecture: The operating system of Mini PC is a real-time Linux (Ubuntu) operating system. The

system architecture diagram is shown in the figure:

X86 CPU

IP:192.168.123.220

Ethernet Switch

Jetson Xavier NX

IP:192.168.123.23

Jetson Xavier NX

IP:192.168.123.24

Jetson Xavier NX

IP:192.168.123.25

Master Controller

IP:192.168.123.10

Leg[FR]:

Motor[0]

Motor[1]

Motor[2]

Leg[FL]:

Motor[0]

Motor[1]

Motor[2]

Leg[RR]:

Motor[0]

Motor[1]

Motor[2]

Leg[RL]:

Motor[0]

Motor[1]

Motor[2]

Depth Camera (1)

Head Front

Depth Camera (2)

Head Down

Depth Camera (3)

Body Left

Depth Camera (4)

Body Right

Depth Camera (5)

Tail

imu Remote

WIFI

2.4G&5.8G

GNSS Module

5G Module

ETH

ETH

ETH

ETH

ETH

2D/3D Rader

(Optional)

ETH

USB

USB

USB

USB

RS485

Users' PC

IP:192.168.123.XX

X

ETH

Users' phone APP

IP:192.168.12.XXX

Remote

1) The user's PC can directly connect the robot's built-in movement controller, perception controller and underlying

controller with Ethernet.

2) The users’ PC can communicate with the underlying controller of the robot and the robot self-loading controller

freely, which facilitate real-time transmission of visual perception data to each other.

3) The self-loading sensors of the robot are fully open and available for secondary development.

4) Develop low-level control: All motors and sensors of the robot can be read and controlled in real time, which is

convenient for directly using open-source robot algorithms

5) Develop high-level control: Users can directly send high-level movement commands to the robots, such as front,

back, left and right.

Loading...

Loading...