4.2. Controller I/O

Description You can use the I/O inside the Control Box for a wide range of equipment including

pneumatic relays, PLCs and emergency stop buttons.

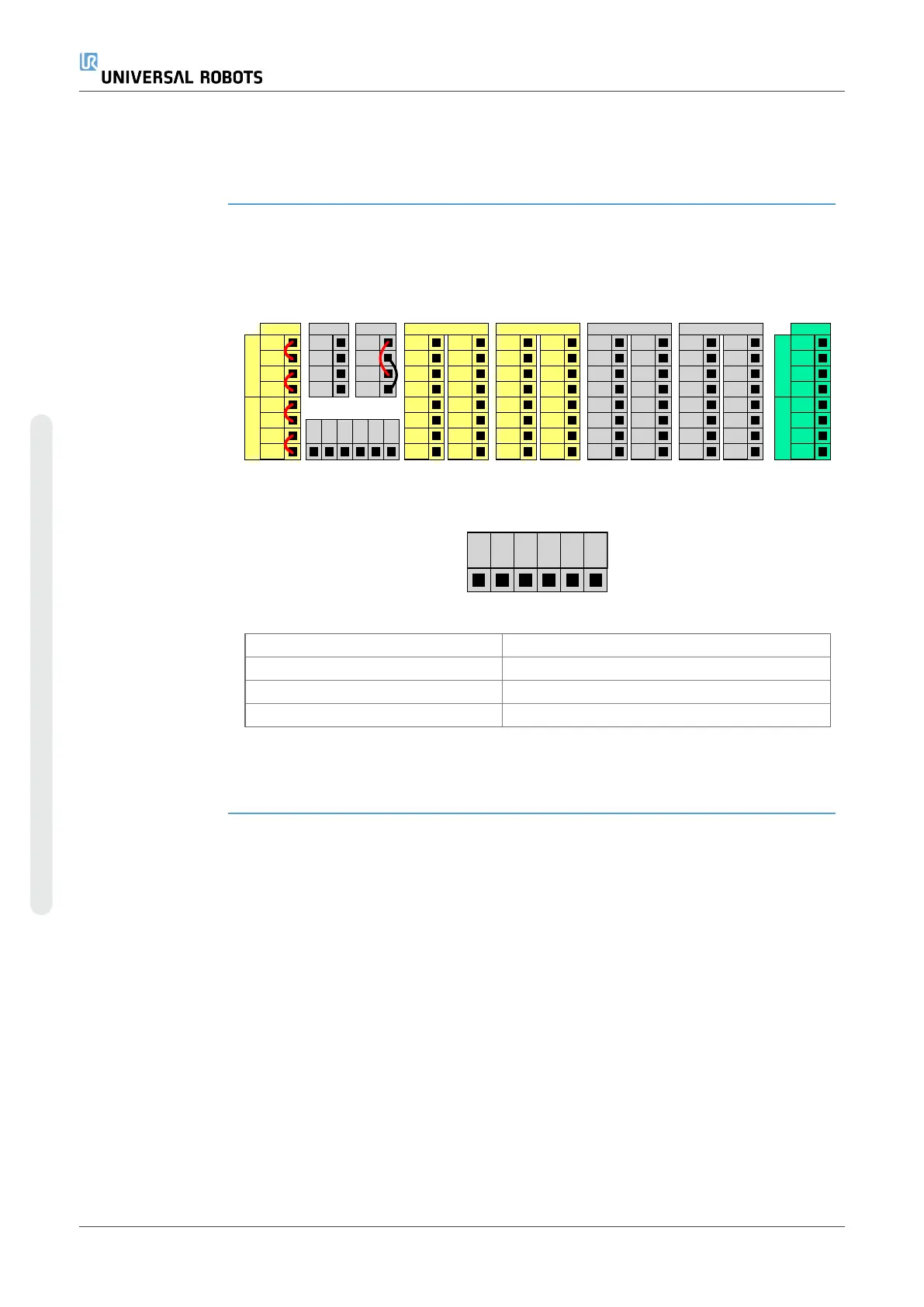

The illustration below shows the layout of electrical interface groups inside the Control

Box.

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safet y

ON

OF F

12V

Remote

24V

0V

P W R

GND

P ow er

24V

CI1

24V

CI2

24V

CI3

24V

CI0

Con figur ab le Inpu ts

24V

CI5

24V

CI6

24V

CI7

24V

CI4

0V

CO1

0V

CO2

0V

CO3

0V

CO0

Con figur ab le Outp ut s

0V

CO5

0V

CO6

0V

CO7

0V

CO4

24V

DI1

24V

DI2

24V

DI3

24V

DI0

Digital Inpu ts

24V

DI5

24V

DI6

24V

DI7

24V

DI4

0V

DO1

0V

DO2

0V

DO3

0V

DO0

Digital Outpu ts

0V

DO5

0V

DO6

0V

DO7

0V

DO4

AG

AI1

AG

AO0

AG

AO1

AG

AI0

Analog

Analog Outp uts

Analog Inp uts

Safeg uar d St op

Emerg en cy S top

GND

0V

24V

DI8

DI9

DI10

DI11

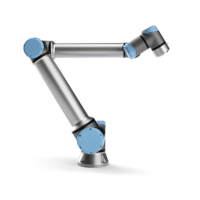

You can use the horizontal Digital Inputs block (DI8-DI11), illustrated below, for

quadrature encoding Conveyor Tracking (see Common specifications for all digital

I/Oon the facing page) for these types of input.

The meaning of the color schemes listed below must be observed and maintained.

Yellow with red text Dedicated safety signals

Yellow with black text Configurable for safety

Gray with black text General purpose digital I/O

Green with black text General purpose analog I/O

In the GUI, you can set up configurable I/O as either safety-related I/O or general

purpose I/O (see partPart II PolyScope Manual).

UR10e 48 User Manual

4. Electrical Interface

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...