10. Troubleshooting

10.1. Troubleshooting procedures

Valmet TS requires no scheduled maintenance. This

chapter contains instructions for possible fault situ-

ations. The device has self-diagnostics that monitors

certain internal measurements and gives an error

message if any of these is outside the allowed range.

Self-diagnostics is able to detect clear faults that are

usually caused by the sensor electronics.

Incorrect measurement results may also be caused

by antenna leaks, contamination, defective antenna

cables, or some process variable that is disturbing the

measurement. These problems may not always be

detected by the self-diagnostics system.

Sometimes the current output signal from the TCU

is incorrect. The actual measurement may work cor-

rectly but the signal sent to the mill system is wrong.

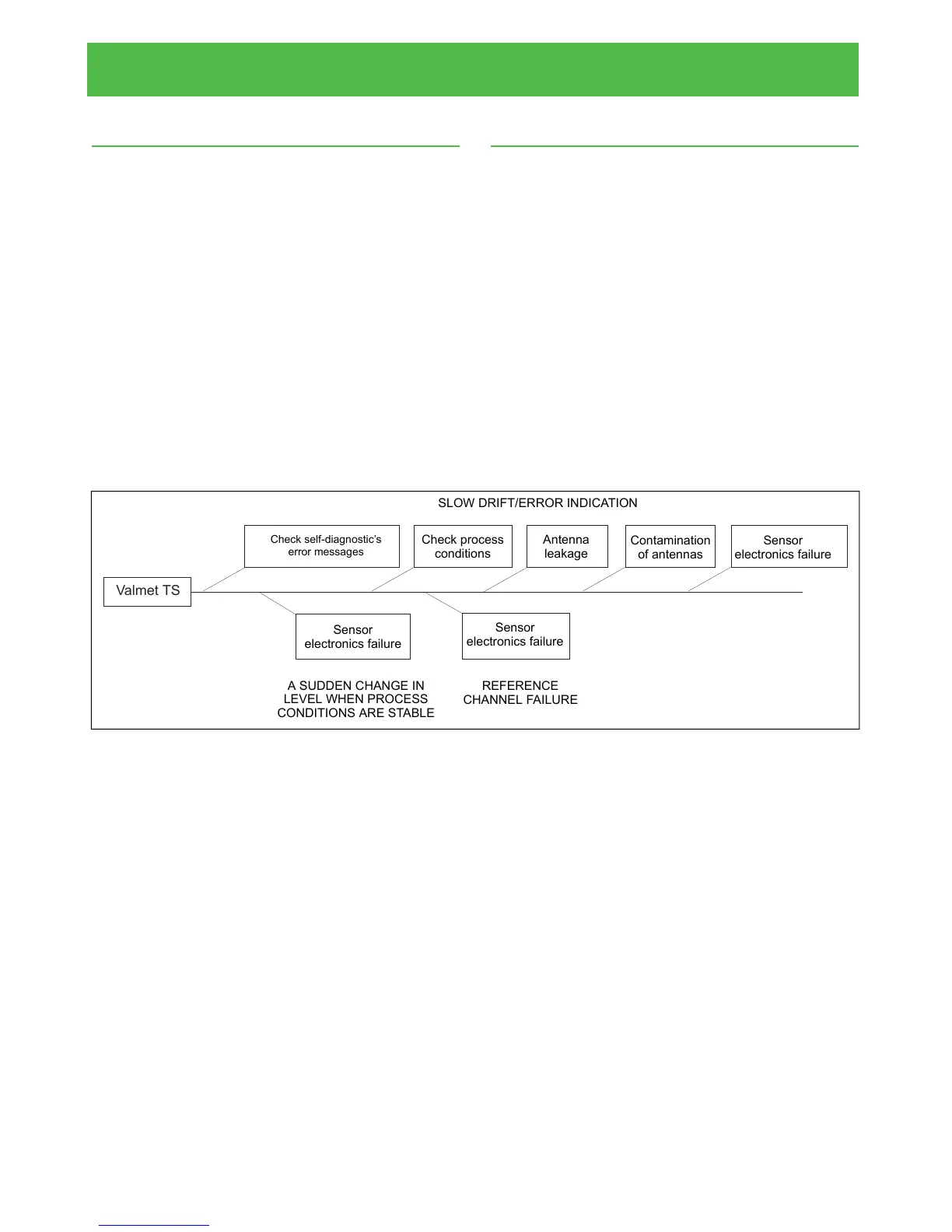

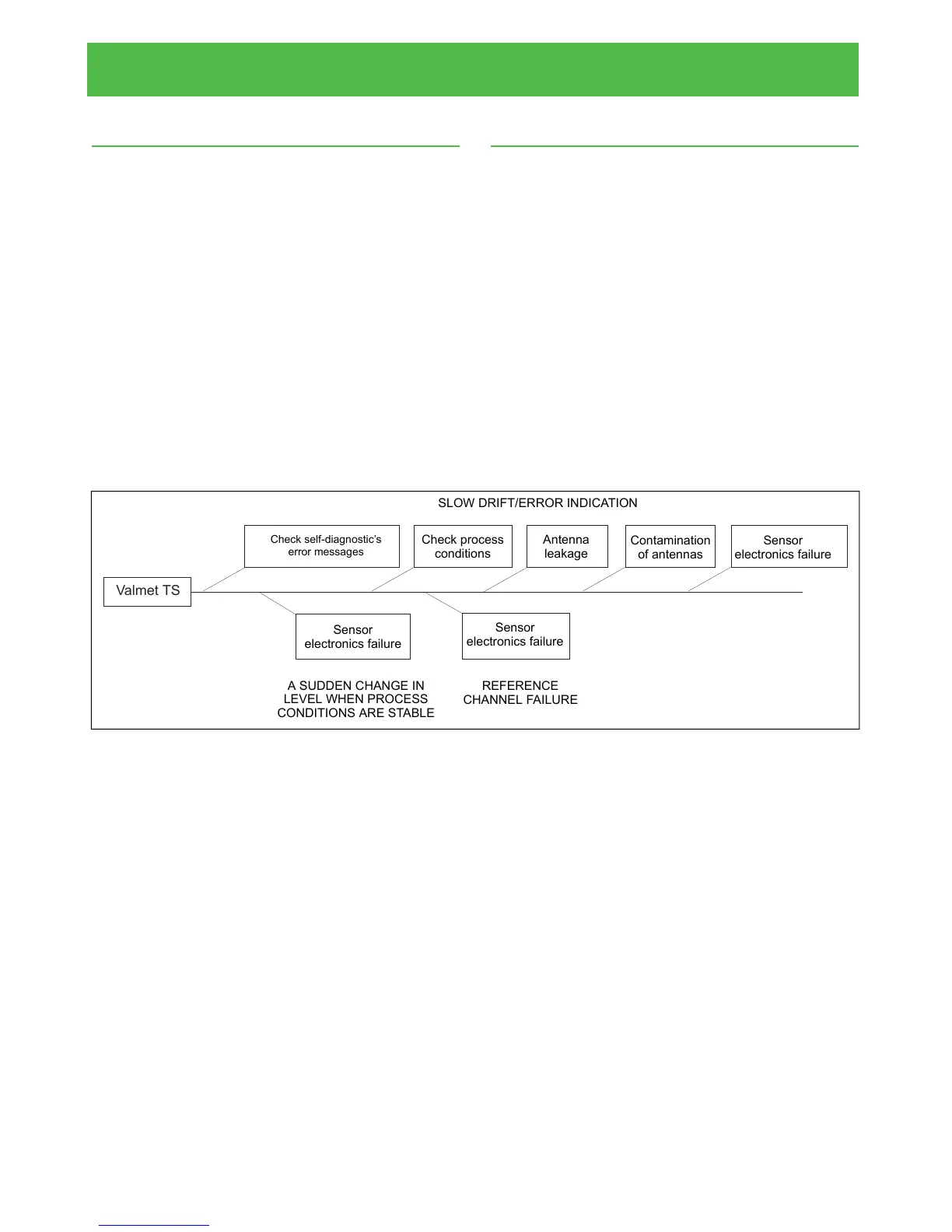

Fig. 1 shows a troubleshooting diagram for different

problem situations.

10.2. Effect of process conditions on measurement

• Air

If the measured sludge contains air, this shows up in

the measurement as a too high total solids content

value. The air may be present in bubbles of different

sizes. Small air bubbles dissolve in water at an approx-

imately 1.5 bar (22 psi) pressure, but large bubbles

may cause problems even at higher pressures. At worst

the error may be up to several % points of total solids.

Air is also a disturbing factor in the process, therefore

the formation of air bubbles should be prevented.

Loading...

Loading...