Installation, Operating & Maintenance Instructions

Series 650 DN 100-250 (I.D. 4“ - 10”), CC-Link

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel +41 81 771 61 61 Fax +41 81 771 48 30 CH@vatvalve.com www.vatvalve.com

280672EB

2010-12-15

77/94

5.1 Maintenance procedures

Keep fingers out of the valve during maintenance work.

Use cleanroom gloves during maintenance work.

Two preventive maintenance procedures are defined for this valve. These are:

• Replacement of isolation seals (gate and body seal of sealing ring) and valve cleaning

• Replacement of actuator and actuator shaft seals

Required frequency of cleaning and replacement of seals is depending on process conditions.

A critical factor influencing the maintenance period is the lifetime of the vacuum grease, being limited under

increased temperature. In this case grease will separate to PTFE and oil. The oil may flow and contaminate

the valve parts.

VAT can give the following recommendations for preventive maintenance:

unheated *)

heated ≤ 80°C *)

heated > 80°C *)

isolation seals (gate and body seal of sealing ring)

200’000 cycles 6 months but

max. 200’000 cycles

3 months but

max. 200’000 cycles

actuator shaft seals

1’000’000 cycles 6 months 3 months

*) This figures are reference values for clean conditions under various temperatures. These values do not include any

impact of the process. Therefore preventive maintenance schedule has finally to be checked for the actual process

conditions.

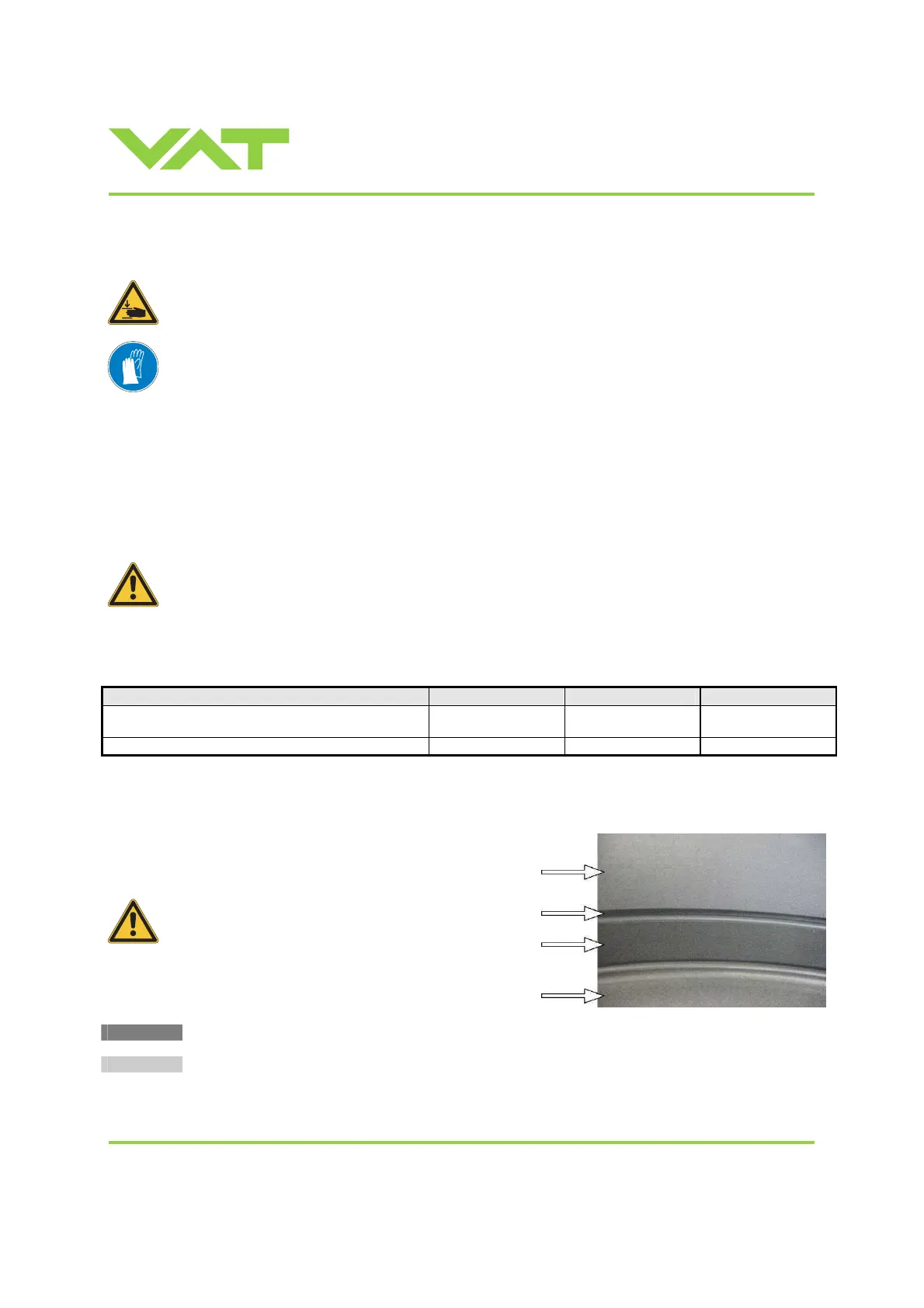

Prevent gap between body and sealing

ring from air gun cleaning. Otherwise

vacuum grease may be distributed and

contaminate the valve.

valve body

gap

sealing ring

pendulum plate

Replacement of isolation seals (gate and body seal of sealing ring) and valve cleaning

Replacement of actuator and actuator shaft seals

Loading...

Loading...