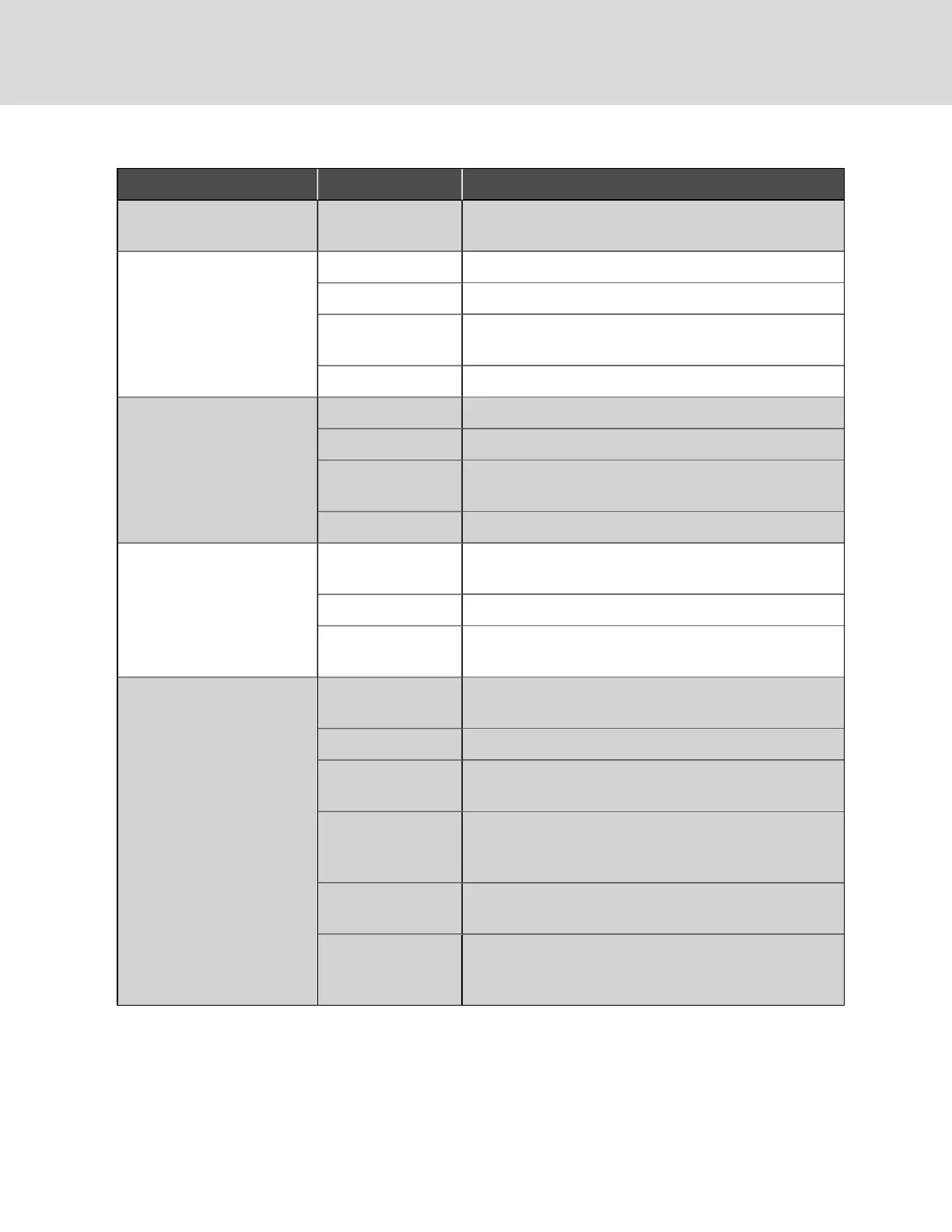

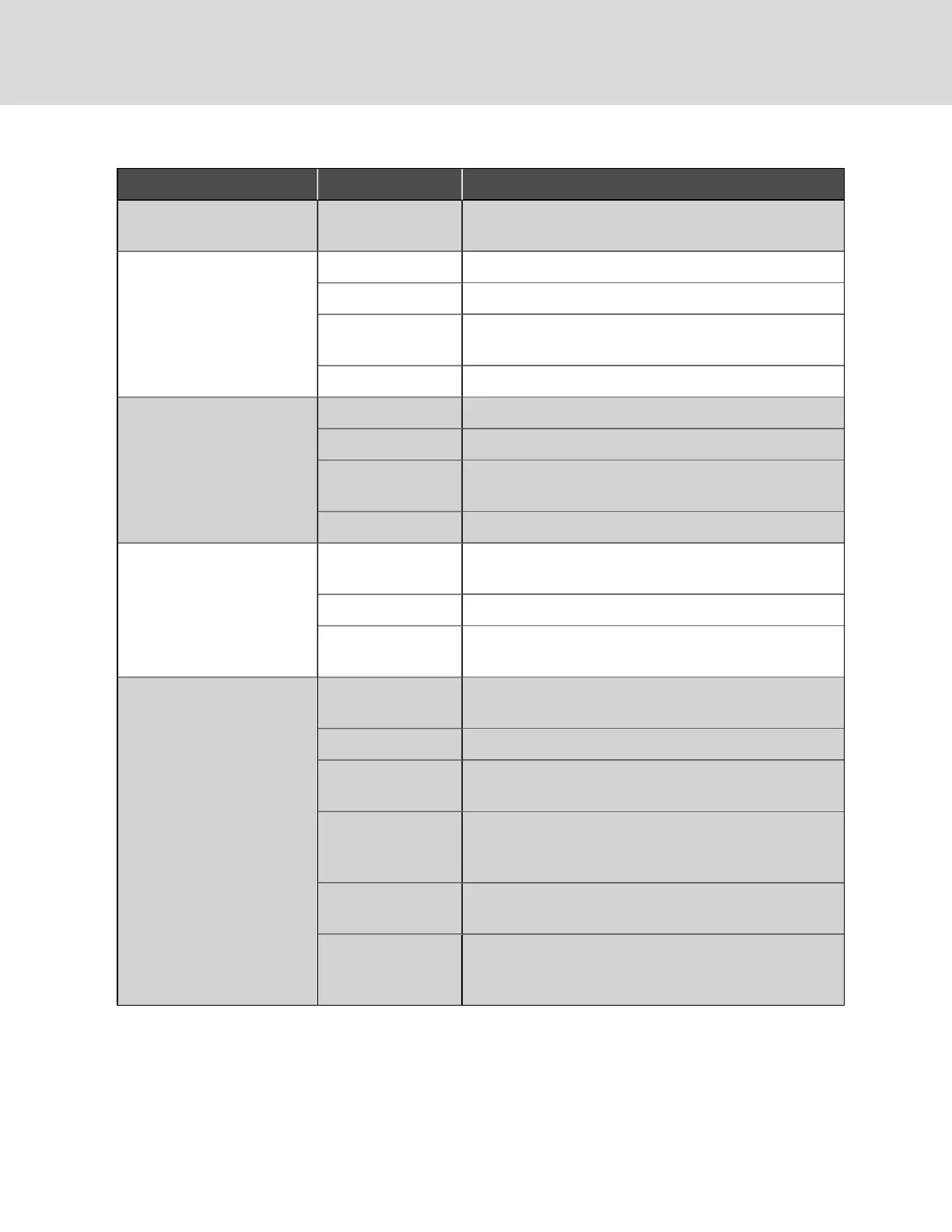

Symptom Possible Cause Check Or Remedy

Excessive leakage around the

pump shaft while operating

Worn seal or packing Replace seal or packing.

Pump performance poor

Worn impeller or seal Replace with new impeller or seal.

Suction lift too high Relocate pump closer to supply.

Motor not up to

speed; low voltage

Larger lead wires may be required. Check for proper line

voltage,±10%.

Worn bearings Replace pump.

Pump has noisy operation

Worn motor bearings Replace pump.

Low discharge head Throttle discharge -- improve conditions

Debris lodged in

impeller

Remove cover and clean out.

Cavitating pumps Adjust system pressures.

Pump discharge pressure too

high

Throttling valve

improperly set

Reset valve to proper differential pressure.

Valve closed in circuit Open all valves downstream of unit.

Strainer clogged or

dirty

Remove strainer plug and clean.

Pump will not operate or no

coolant flow

No power to pump

motor

See Unit will not operate on the previous page in this table.

Low coolant level Check coolant level.

Tubes plugged in

cooling coil

Flush coil with reputable cleaner.

Valve closed

downstream of

cooling unit

Open all valves.

Strainer clogged or

dirty

Remove strainer plug and clean.

Pump cavitating

(erratic gauge

operation)

Possibility of air in lines. Bleed all components. Check surge

tank to pump inlet connection. Check for piping restrictions.

Table 8.1 Troubleshooting Symptoms and Checks (continued)

Vertiv | Liebert® Drycooler Installer/User Guide

52

Loading...

Loading...