NOTE: Installation and service of this equipment should be done only by properly-trained and qualified personnel who

are specially-trained in the installation of air-conditioning equipment.

The electrical connections are described in the submittal documents included in the Submittal Drawings Contents on

page65.

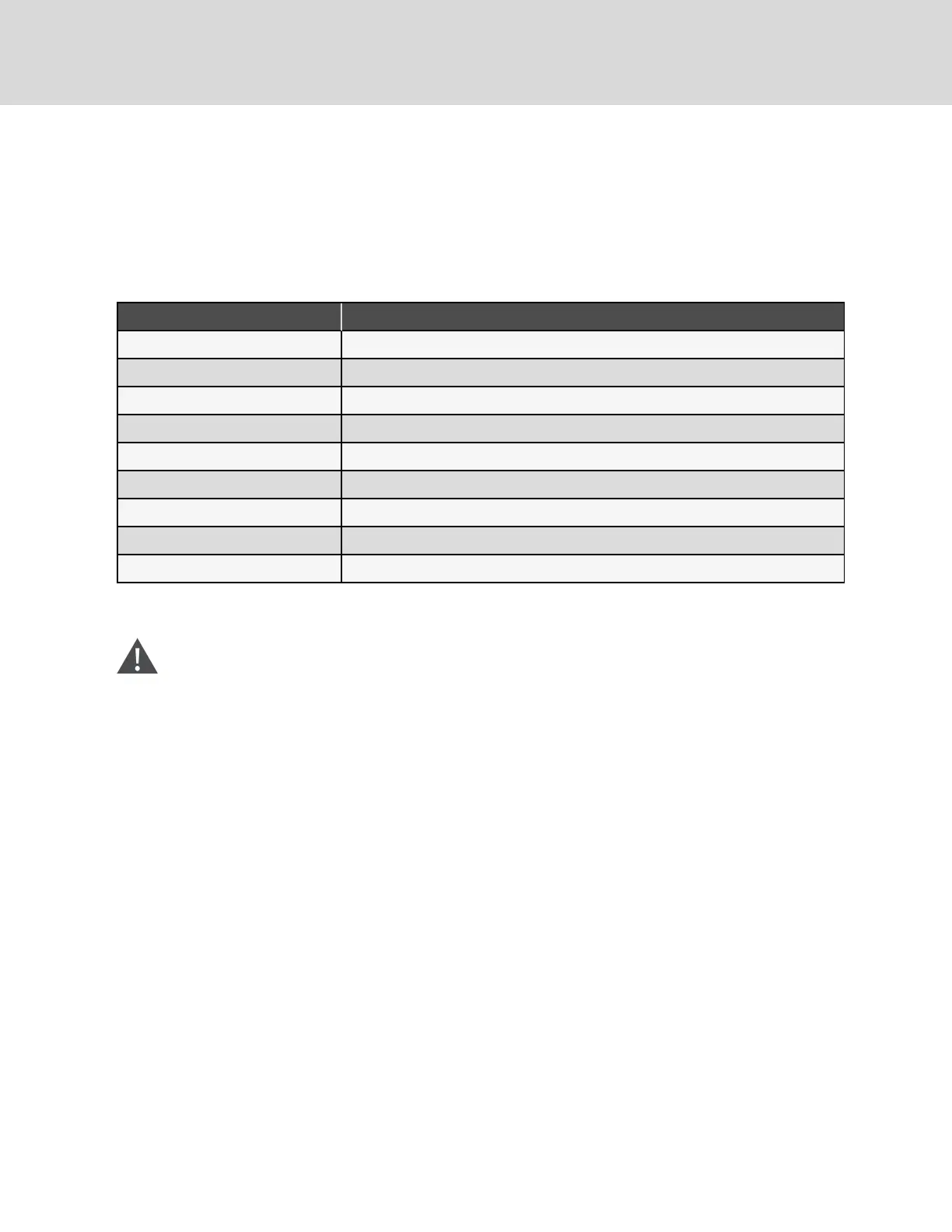

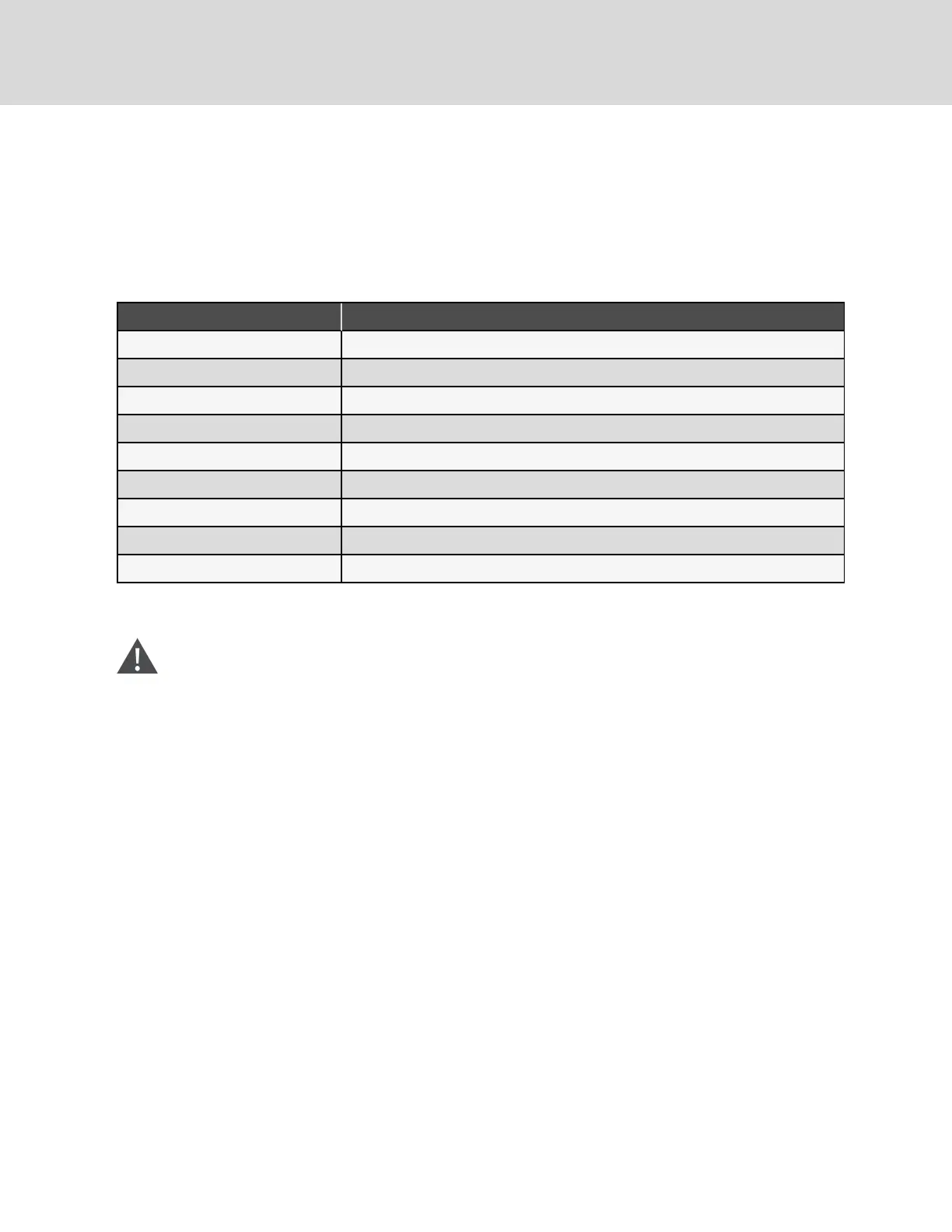

The following table lists the relevant documents by number and title.

Document Number Title

DPN000277 Electrical field connections, 1 fan DSF/DDF drycooler with pump control

DPN000276 Electrical field connections, 1, 2, 3 and 4 fan DSO/DDO drycooler with pump control

DPN000703 Electrical field connections, 6 and 8 fan DSO/DDO drycooler with pump control

DPN000702 Electrical field connections, 6 and 8 fan DDNC drycooler without pump control

DPN000704 Electrical field connections, 6 and 8 fan DDNL/DDNT drycooler without pump control

DPN000282 Electrical field connections, Fluid-temperature control drycooler, Quiet-Line

DPN000722 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with no control

DPN000723 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with DSO/DDO pump control

DPN000724 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with DDNL and DDNT pump control

Table 6.1 Electrical Field Connection Drawings

6.1 Line Voltage Wiring

WARNING! Risk of electrical fire and short circuit. Can cause property damage, injury or death. Select and

install the line side electrical supply wire and overcurrent protection device(s) according to the specifications

on the unit nameplate(s), per the instructions in this manual and according to the applicable national, state

and local code requirements. Use copper conductors only. Verify that all electrical connections are tight.

Unit-specific wiring diagrams are provided on each unit.

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.Prior to

connecting any equipment to a main or alternate power source (for example: back-up generator systems) for start-up,

commissioning, testing, or normal operation, ensure that these sources are correctly adjusted to the nameplate

voltage and frequency of all equipment to be connected. In general, power-source voltages should be stabilized and

regulated to within ±10% of the load nameplate nominal voltage. Also, ensure that no three-phase sources are single-

phased at any time.

Drycooler-rated voltage should be verified with available power supply before installation. Refer to the unit’s electrical

schematic and serial tag for specific electrical requirements.

Line voltage electrical service is required for all drycoolers at the location of the drycooler. If the drycooler contains pump

controls, the pump package voltage must match the drycooler voltage. See the unit's serial tag for specific electrical

requirements of the drycooler and any pump package. A unit disconnect is standard on all drycoolers. Site disconnect (s)

may also be required per local code to isolate the drycooler/pumps for maintenance. Route the supply power to the site

disconnect switch and then to the drycooler. Route the conduit through the hole provided in the cabinet. Connect earth

ground to lug provided near the terminal board. Refer to the appropriate drawing in the Submittal Drawings Contents on

page65.

Vertiv | Liebert® Drycooler Installer/User Guide

40

Loading...

Loading...