Humidifier Water Supply Line

Units supplied with the optional humidifier package have a 1/4 in. (6.4 mm) copper compression fitting

connection for water inlet. Supply pressure range is 10 psig to 150 psig. Required flow rate is 1gpm

(3.8lpm). A shut-off valve should be installed in this line to isolate the humidifier for maintenance.

NOTE: Do NOT route humidifier supply line in front of filter box access panel.

Chilled Water Piping—On chilled water units install manual service shut-off valves at the supply and

return lines of each unit. These shut-off valves are used for routine service or emergency isolation of the

unit.

Chilled water supply and return lines must be insulated. Insulating them will prevent condensation of the

water supply and return lines to the unit.

The minimum recommended water temperature is 42°F (5.5°C). Connection sizes are 1-1/8" (28.6mm) OD

copper.

Water/Glycol Piping—Water- and glycol-cooled systems require coolant loop connections as specified in

the condensing unit installation instructions.

Refrigerant R-407C Piping—All split systems require two refrigerant lines (an insulated copper suction

line and a copper liquid line) between the evaporator and the condensing unit.

WARNING! Risk of explosive discharge of high pressure refrigerant. Can cause serious injury.

Relieve refrigerant system pressure before working with piping/connections.

Two possible methods exist for installing the copper suction and liquid lines.

• Close coupling the units together using the quick connects. (See Figure 7.8 on page39).

• Using an optional sweat adapter kit and hard piping between the two units.

All refrigeration piping should be installed with high temperature brazed joints. Prevailing good

refrigeration practices should be employed for piping supports, leak testing, evacuation, dehydration and

charging of the refrigeration circuits. The refrigeration piping should be isolated from the building by the

use of vibration isolating supports. To prevent tube damage when sealing openings in walls and to reduce

vibration transmission, use a soft flexible material to pack around the tubes.

When installing remote condensing units above the evaporator, the suction gas line should be trapped at

the evaporator. This trap will retain refrigerant oil in the off cycle. When the unit starts, oil in the trap is

carried up the vertical riser and returns to the compressor.

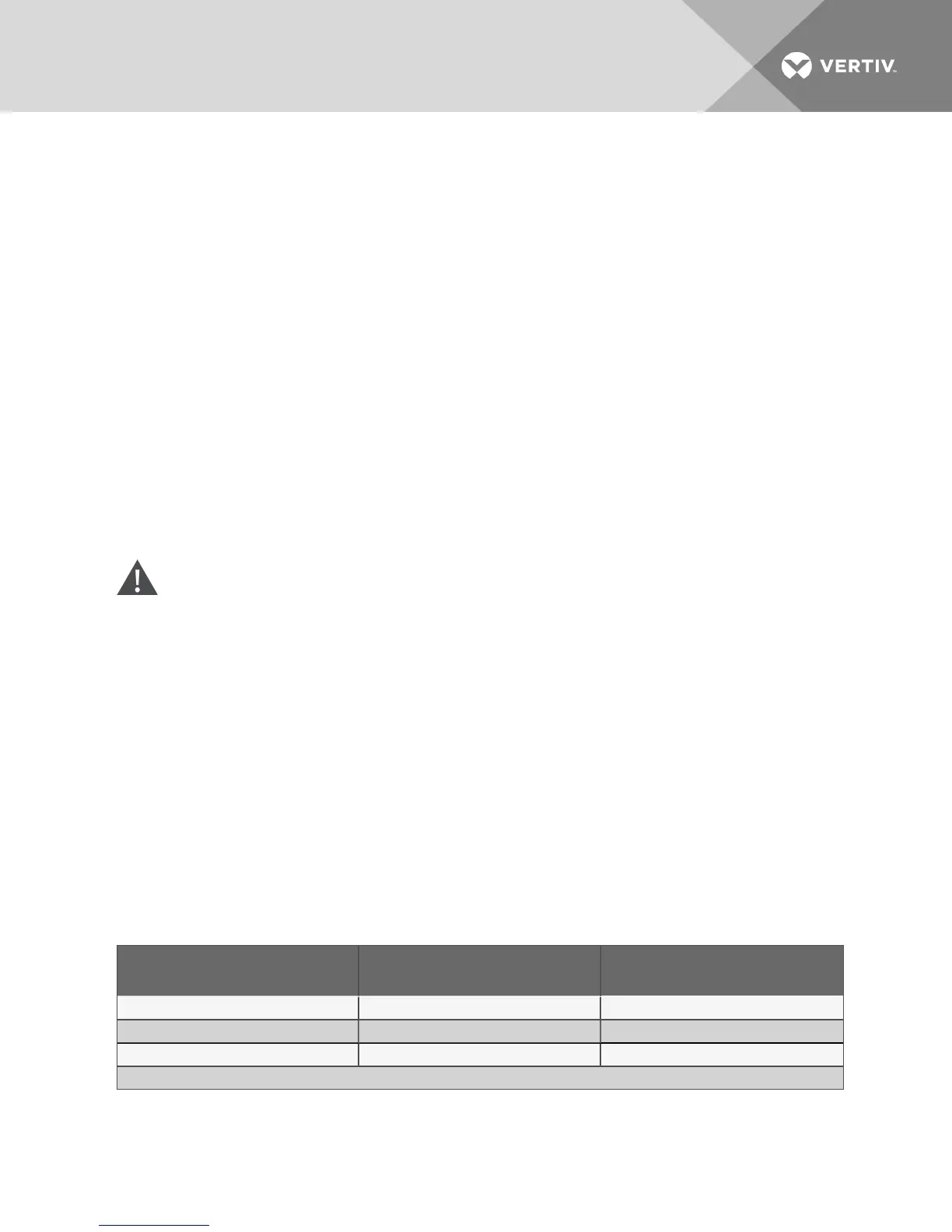

Equivalent Pipe

Length, ft (m)

Liquid Suction

50 (15) 1/2" 1-1/8"

100 (30.5) 5/8" 1-1/8"

150 (45.7) 5/8" 1-3/8"

Suction line and liquid line sizing based on < 3 psi pressure drop in each and suction line refrigerant velocities >1000FPM (5.1m/s) for proper oil return.

Table 7.6 Recommended refrigerant line sizes

Vertiv | Liebert Mini-Mate2—5 ton User Manual| 31

Loading...

Loading...