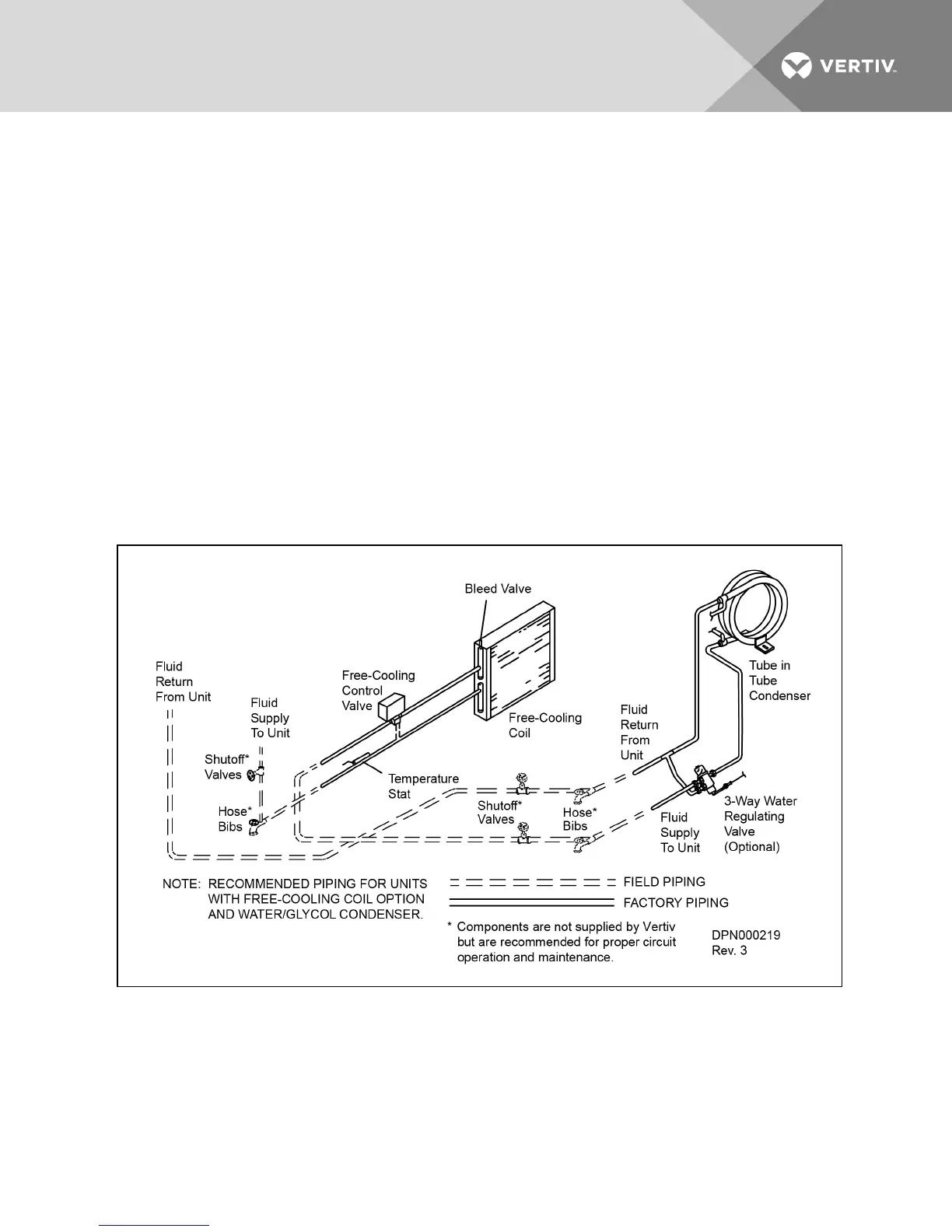

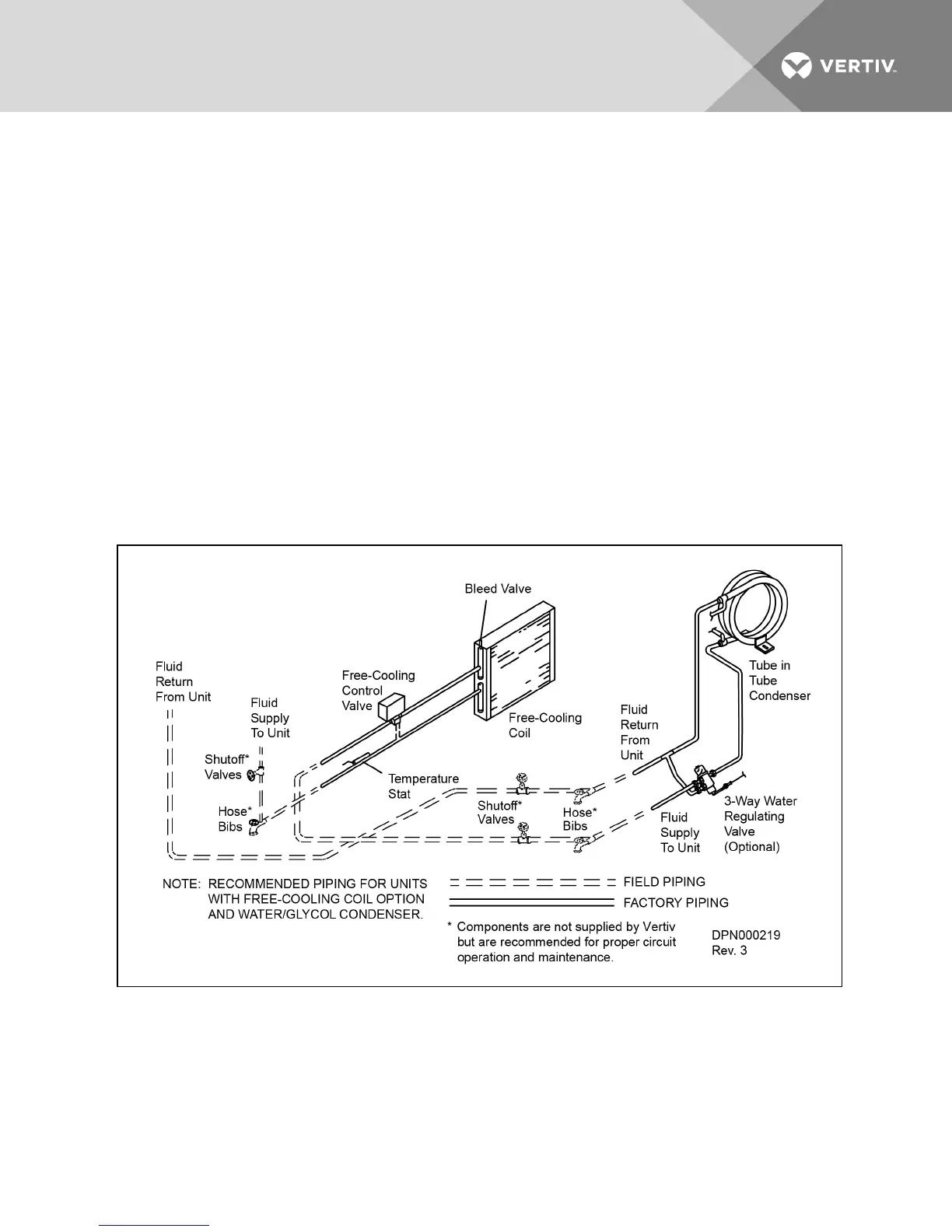

7.8 Optional Equipment Piping

7.8.1 Free-Cooling Coil

The free-cooling coil is a secondary coil located downstream of the DX coil. The free-coiling coil does not

operate at the same time as the DX coil. A temperature sensor is factory-mounted to the free-cooling

piping. If the water temperature is less than the set temperature (usually 45°F [7.2°C]), the 3-way valve

opens to allow chilled water flow to the free-cooling coil and the compressor is locked off. If the water

temperature is above the set temperature, the 3-way valve closes (bypasses) and enables the compressor.

To keep deposits from building up in the free-cooling coil, an adjustable timer is factory-set to flush every

400 minutes.

NOTE: If the free-cooling coil is piped to an open water tower, a CU/NI (copper-nickel) type coil must

be ordered to prevent corrosion of the copper tubes; or a heat exchanger must separate the tower

water from the free-cooling loop.

On water-cooled systems, the free-cooling coil outlet can be field piped to the condensing unit inlet,

provided a 3-way regulating valve has been installed within the water/glycol condensing unit (see Figure

7.17 below).

Figure 7.17 Optional free-cooling coil (3-way valve) on water/glycol units

7.8.2 Hot Water Reheat Coil

Building hot water can be piped to a factory-installed hot water reheat coil, located downstream of the

cooling coil. A factory-installed solenoid valve opens upon a call for reheat.

Vertiv | Liebert Mini-Mate2—5 ton User Manual| 52

Loading...

Loading...