6

Liebert

®

PDX, EconoPhase Version - UM - 265133 - 29.08.2019

1.8 - Description of Liebert

®

EconoPhase Operation

The Liebert

®

EconoPhase unit enables the Liebert

®

PDX system

to operate in any of three modes to control temperature, depending

on the outdoor temperature and the load.

• Compressor Mode

• Pump Mode

• Mixed Mode

When the outdoor temperature becomes low enough to provide

the required temperature dierence between the inside air and

the outside air, there is no need to compress the refrigerant to a

higher pressure/temperature. When the outdoor temperature is

low enough, the system switches from Compressor Mode to Pump

Mode or to Mixed Mode.

• Compressor Mode: All available compressors may be used

to maintain the control temperature. All the available Liebert

®

EconoPhase pumps are O. The control will typically run in

this mode when the load and temperatures are such that full

or partial Liebert

®

EconoPhase operation is not possible, or

because certain pumps have experienced alarms.

• Pump Mode: All of the available pumps may be used to

maintain the Control Temperature. All the compressors in the

system are O. The control will typically run in this mode when

load and temperatures permit.

• Mixed Mode: The pump in Circuit 1 is On and the compressor(s)

in Circuit 2 is On. Some systems may not have Mixed Mode

capability, depending on the manufacture date. Contact the

factory to inquire about a software upgrade.

1.8.1 EconoPhase Control

EconoPhase operation has three main controlled parameters:

• return or supply air temperature control

• refrigerant temperature

• pump pressure dierential (outlet pressure - inlet pressure)

Room Temperature

When the system is in Pump Mode, the room temperature is

controlled by modulating the pump speed with a variable frequency

drive. The load requirement will determine if one pump or two

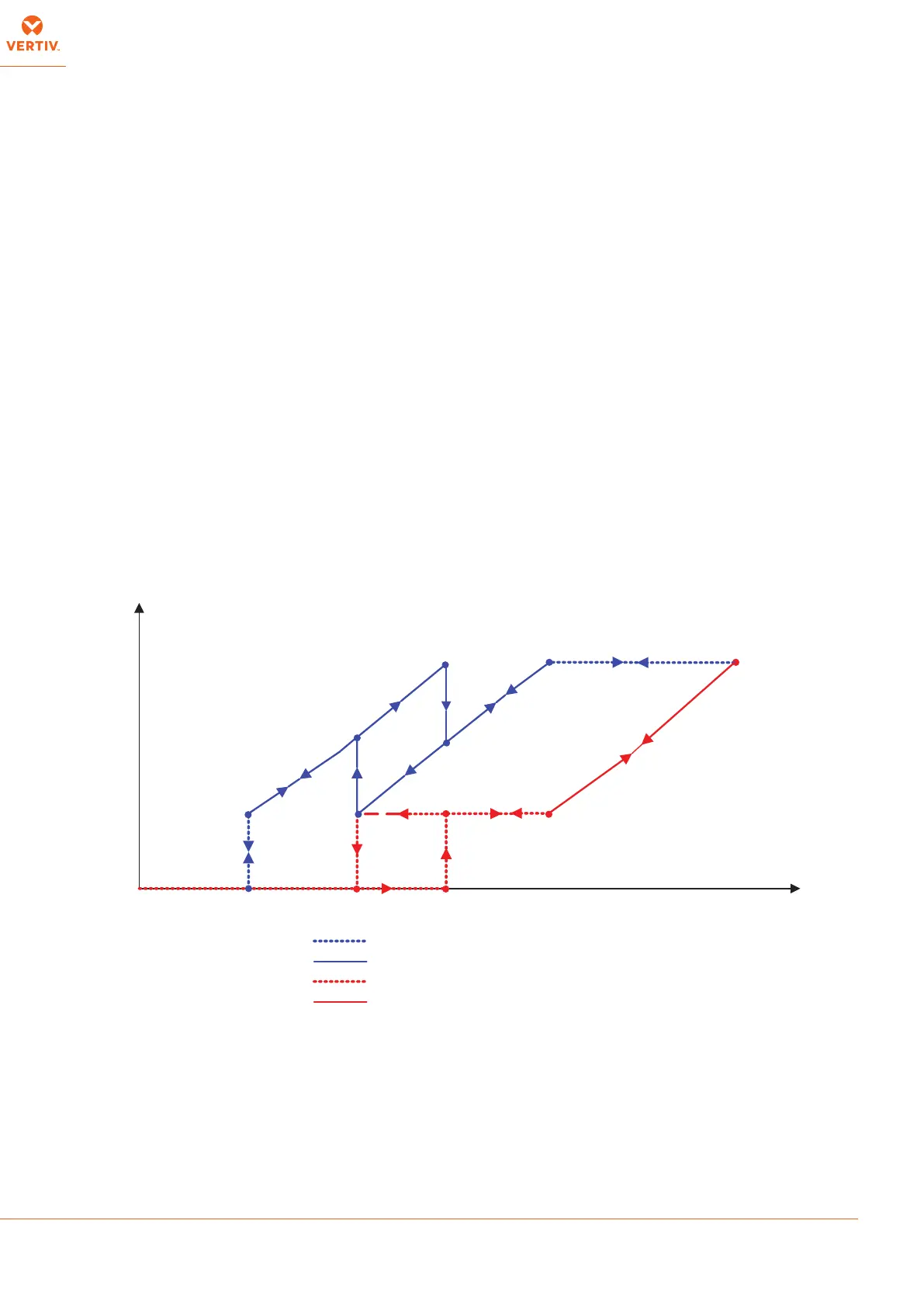

are needed. Figure 8 shows the sequence of operation in terms

of pump speed. Minimum speed is 45% and maximum speed is

100%. See Table 2 for more detail on the events shown in Figure 8

and the conditions that trigger action.

The pump startup routine calls for a start speed of 80%. The pump

will run for up to 60 seconds at 80% with the EEV at 60% while

waiting on the pump pressure dierential to reach at least 0.83 bar

to indicate that ow has been established. If the pump establishes

ow, the speed will change from 80% to the required control speed

as shown on the curves in Figure 6.

Fig.6 - Two-circuit pump control

E

I

C

H

F

K

J

A

B

100%75%55%40%20%0

Minimum

Pump

Speed

Maximum

Pump

Speed

Pump

Speed

y

x

Capacity

Pump 2

L

G

D

Pump 1

Pump 2 under manual control

Pump 2 under PID control

Pump 1 under manual control

Pump 1 under PID control

Loading...

Loading...