17

Liebert

®

PDX, EconoPhase Version - UM - 265133 - 29.08.2019

4.2 - Vacuum creation and refrigerant charge

NOTICE: Check the refrigerant type to be used

on the data plate of the air conditioner and on the

refrigerating compressor.

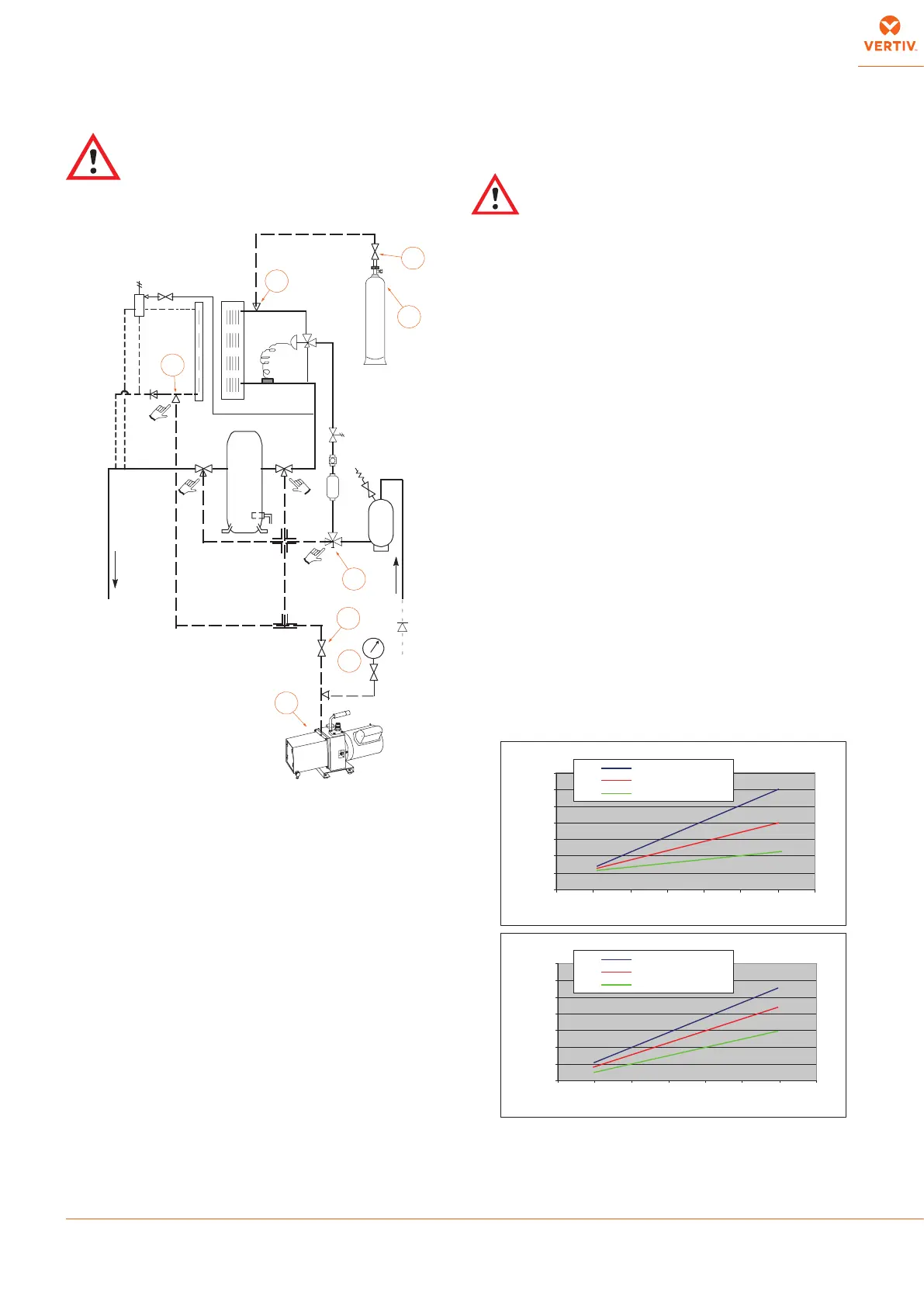

Fig. 9 - Vacuum Pump and refrigerant charging cylinder

connections for vacuum creation and refrigerant charge

4.2.1 - R410A precharge

1. Open all cocks of the system including those used for

pressurizing (ambient unit and condensing unit).

With this operation all the components of the refrigerating

circuit must be subject to vacuum.

2. Connect a proper, high eciency vacuum pump (10) suitable

for polyester oils to the couplings:

- Compressor intake and delivery using the 5/16

Schrader valves welded on the piping.

- Schrader coupling (12) t on the liquid receiver.

- Schrader coupling (13) t on the compressor or fan space,

if the reheating coil option is available.

3. Provide for a connection with refrigerant cylinder before

making vacuum.

4. Make the system vacuum up to 0.3 absolute mbar and after

3 hours check if 1.3 absolute mbar have not been exceeded.

This condition ensures a humidity lower than 50 ppm inside

the system. If the complete vacuum is not possible, this means

that there are some leaks (to be removed according to the

instructions in 6 below).

NEVER USE THE COMPRESSOR TO CREATE A VACUUM

(THIS INVALIDATES ITS GUARANTEE).

5. Break the vacuum as follows:

a) Close the cock (10a) for the vacuum pump (10).

b) Open the cock of the refrigerant cylinder (11a) until the

system reaches a pressure value of about 1 bar.

NOTICE: The refrigerant must be introduced and

charged on evaporator inlet (5/16 Shrader valve)

taking only liquid uid from the cylinder.

c) At this point both the vacuum pump and the refrigerant

cylinder can be disconnected as follows:

c1) close the cylinder cock (11a)

c2) close the way 5/16” SAE of the connected Schrader

valves.

6. Inspect all connections/joints using a leak detector. If a nleak

is found, empty the pipes and the condenser, seal the leak and

repeat the instructions in 3) - 6).

7. Now the machine is ready for completing the charge and the

start-up.

8. Charge the refrigerant (ONLY LIQUID) by means of the charge

valve placed at the evaporator inlet.

4.2.2 - R410A refrigerant charge

1. Start the unit as described in para. 7.1.

2. Manually start the compressor (when the unit is equipped with

tandem compressors start both of them), ensure the unit is not

in the dehumidication phase).

3. Guarantee a constant condensing temperature (preferably

42-45°C); if necessary, partially obstruct the condenser coil

surface or limit its ventilating power to obtain these conditions.

4. Charge the unit until the working conditions of the entire

refrigeration circuit have become normal.

5. Using a manometer, check that the evaporating temperature

is above 0

0

C.

6. Verify that the superheat is 6-8 K (to do this refer to para. 10.1).

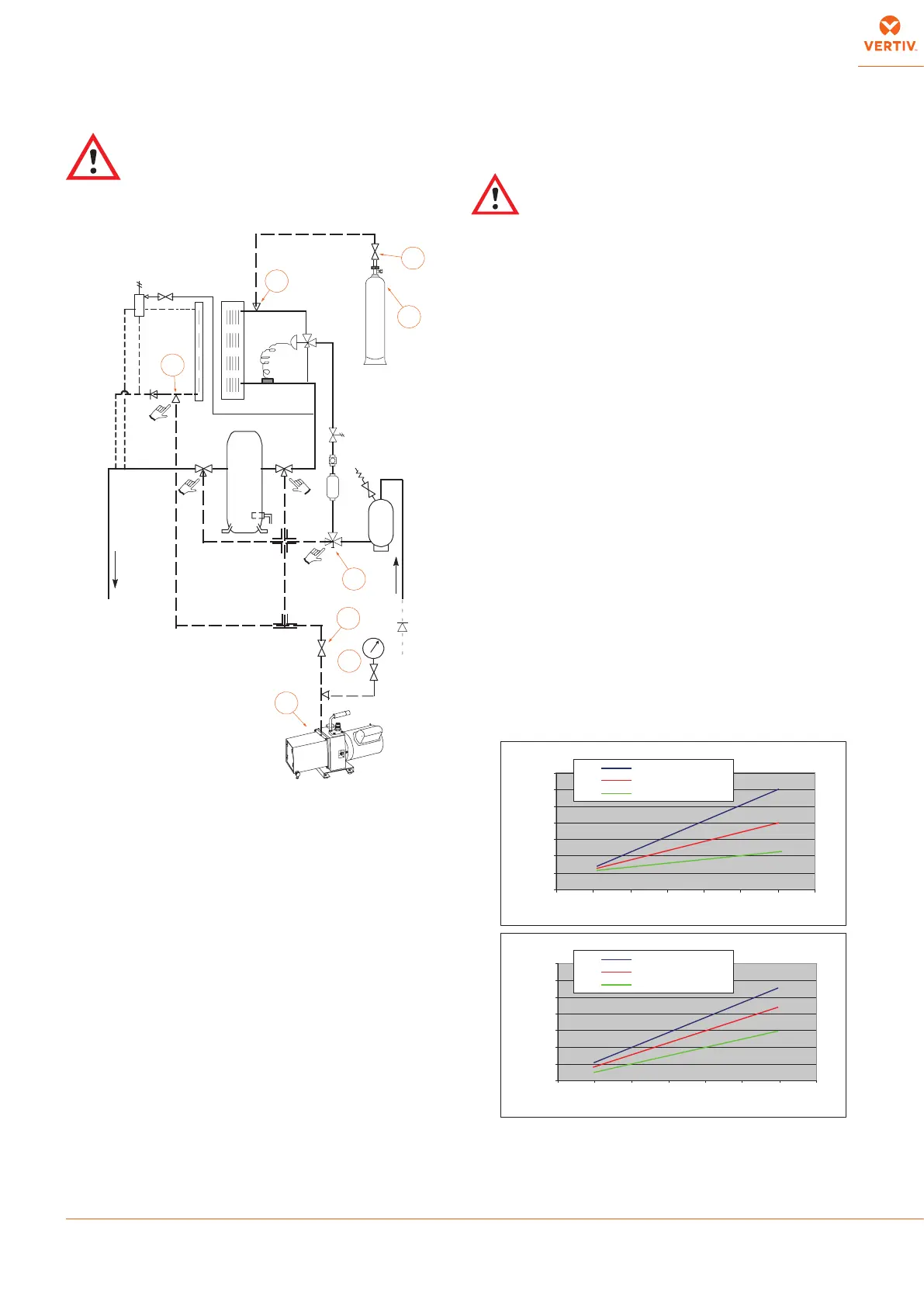

7. Follow the diagram below to dene the charge. Measuring

condensing temperature and evaporating temperature at

the compressor, nd in the diagram the target subcooling

then adjust the charge to match the target subcooling found

(subcooling should be measured at the expansion valve inlet).

With scroll compressor cooling systems, during the charge

adjustment, the compressors have to be at the full capacity.

4.3 - Refrigeration circuits (see Enclosure D)

See drawings in Enclosure D.

R.L.

10

(*)

10a

11

11a

14

13

12

10b

(*)only with reheating coil (optional)

PDX

0

2

4

6

8

10

12

14

25 30 35

40 45 50 55 60

Condensing temperature[°C]

2÷5°Cevap. te mp.

5÷8°Cevap. te mp.

8÷12 °C evap.temp.

subcooling [K]

Condensing temperature[°C]

subcooling [K]

PDX SMARTAISLE APPLICATION

0

2

4

6

8

10

12

14

25 30 35 40 45 50 55 60

8÷12 °C evap.temp.

12÷15 °Cevap.temp.

15÷20 °Cevap.temp.

Loading...

Loading...