19

Liebert

®

PDX, EconoPhase Version - UM - 265133 - 29.08.2019

• Right side: internal low voltage eld wiring pathways

• Left side: internal high voltage eld wiring pathways

• Use the cable bushing on the back of the panel to get into the

electrical panel.

• Use cable tie to x the power and low voltage cable to the

electrical panel.

For cable entrance holes details see Enclosure D.

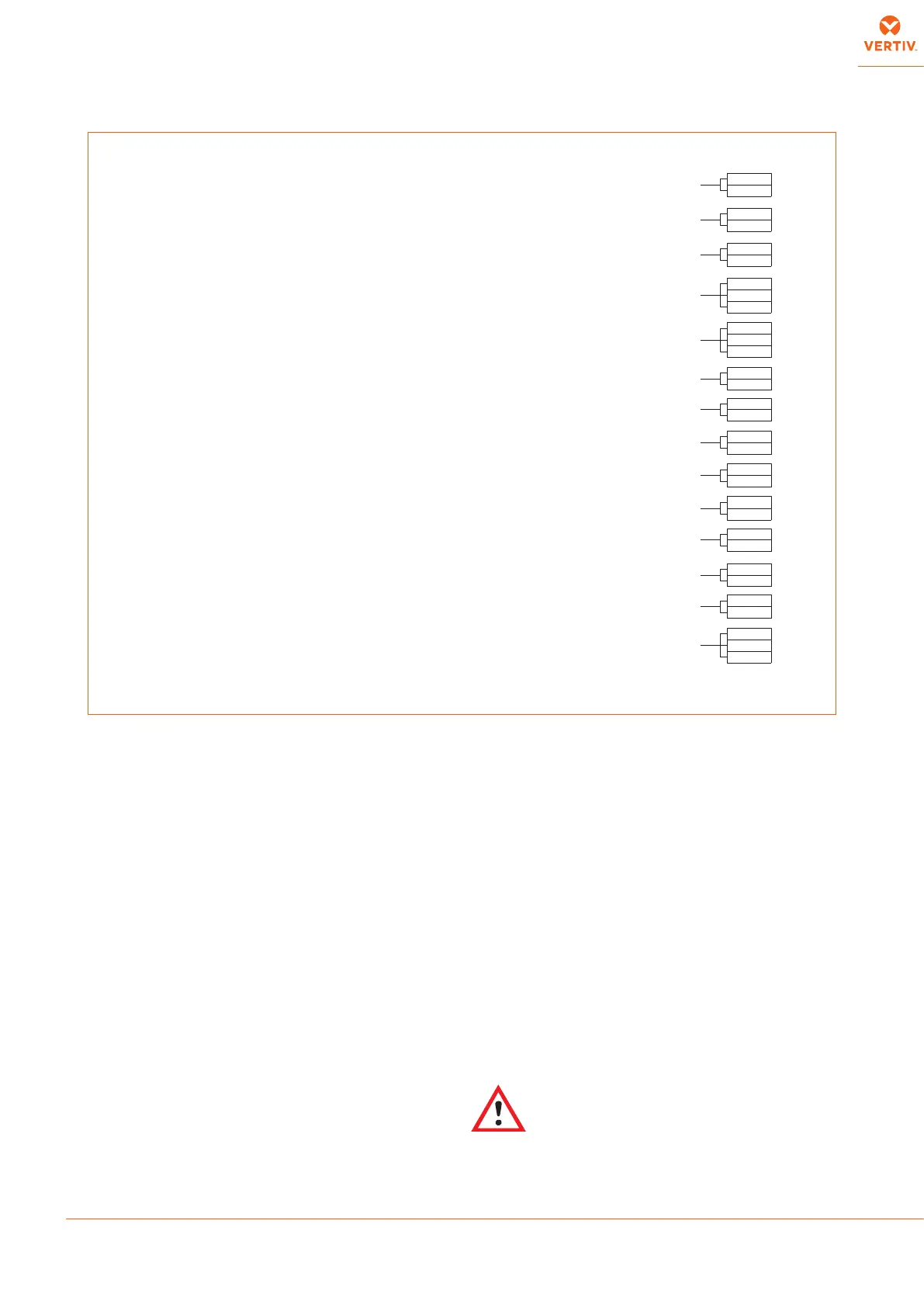

Wiring connections (Fig. 13):

• Connection for remote on-o must be done by the installer.

• The General Alarm terminals allow remote alarm signaling.

• In case of short circuit, check the sticking of the involved

switch and replace it.

6.4 - Protection degree IP2x check

After whole of the connections and installation works, comprising

ceiling elements (plenum, ducting) and oor elements (base frame),

check and verify the protection degree IP2x (protection against nger

access, std. IEC 60364-1) at the boundary of the air conditioner.

6.5 - Protective features of EC fan

The EC fan has been provided with the following protective features:

• Electronics overheating protection

• Motor overheating protection

• Locked rotor protection

• Short circuit at the motor output

With any of these failures, the motor stops (electronically - no

potential separation), the status relay is released.

NO automatic restart. To reset the alarm, power supply has to be

switched o for min. 20 s once motor is at standstill.

• Mains under-voltage detection:

if mains voltage falls below 3ph/290Vac (typical value) for 5s

minimum, motor will be switched o (only by electronics, no

potential separation), status relay is released.

If mains voltage returns to correct values, the motor will

restart automatically.

• Phase failure recognition:

if one phase fails for 5s minimum, motor will be switched o

(only by electronics, no potential separation), status relay is

released.

If all 3 phases return to correct values, the motor will

restart automatically within 10-40s.

The power supply for an external speed setting potentiometer is

short-circuit protected.

Motor is overload-protected via motor current limitation.

Warning! Leakage current of the motor is approx. 7 mA.

Fig. 13 - Available terminals

cloggedlter (CF)

(CLOSE =OK)

remote on-o

(CLOSE =ON)

smokestat restat(AAP)

optional (CLOSE =ON)

(*) water leakage (LWD)

GENERALALARM

(400, 401NC=alarmorunito)

operatingfan

(CLOSE =ON)

operatingcompressor1

(CLOSE =ON)

user alarm 1

(CLOSE =OK)

user alarm 2

(CLOSE =OK)

operatingcompressor2

(CLOSE =ON)

WARNING

(300, 301NC=warning or unit o)

(Cooling +Electr. heating+Humidication)

AUXILIARY TERMINAL BOX

86

83

400 (NC)

401(C)

402(NO)

70

71

72

73

76

77

78

79

86

030

86

82

300 (NC)

301(C)

302 (NC)

74

75

4compressors

394

0394

362

361

710

720

operatingcompressor3

(CLOSE =ON)

operatingcompressor4

(CLOSE =ON)

Note : Connect 70C terminal withLiebert MC Condenser terminal 700, connect 71C terminal withLiebert MC Condenser terminal 710,

connect 230C terminal withLiebert MC Condenser terminal 230.

70CLiebert MC Condenser, common controlsignal

71CLiebert MC Condenser, circuit1controlsignal

230C LiebertMCCondenser, circuit 2control signal

70C

71C

230C

Loading...

Loading...