21

Liebert

®

PDX, EconoPhase Version - UM - 265133 - 29.08.2019

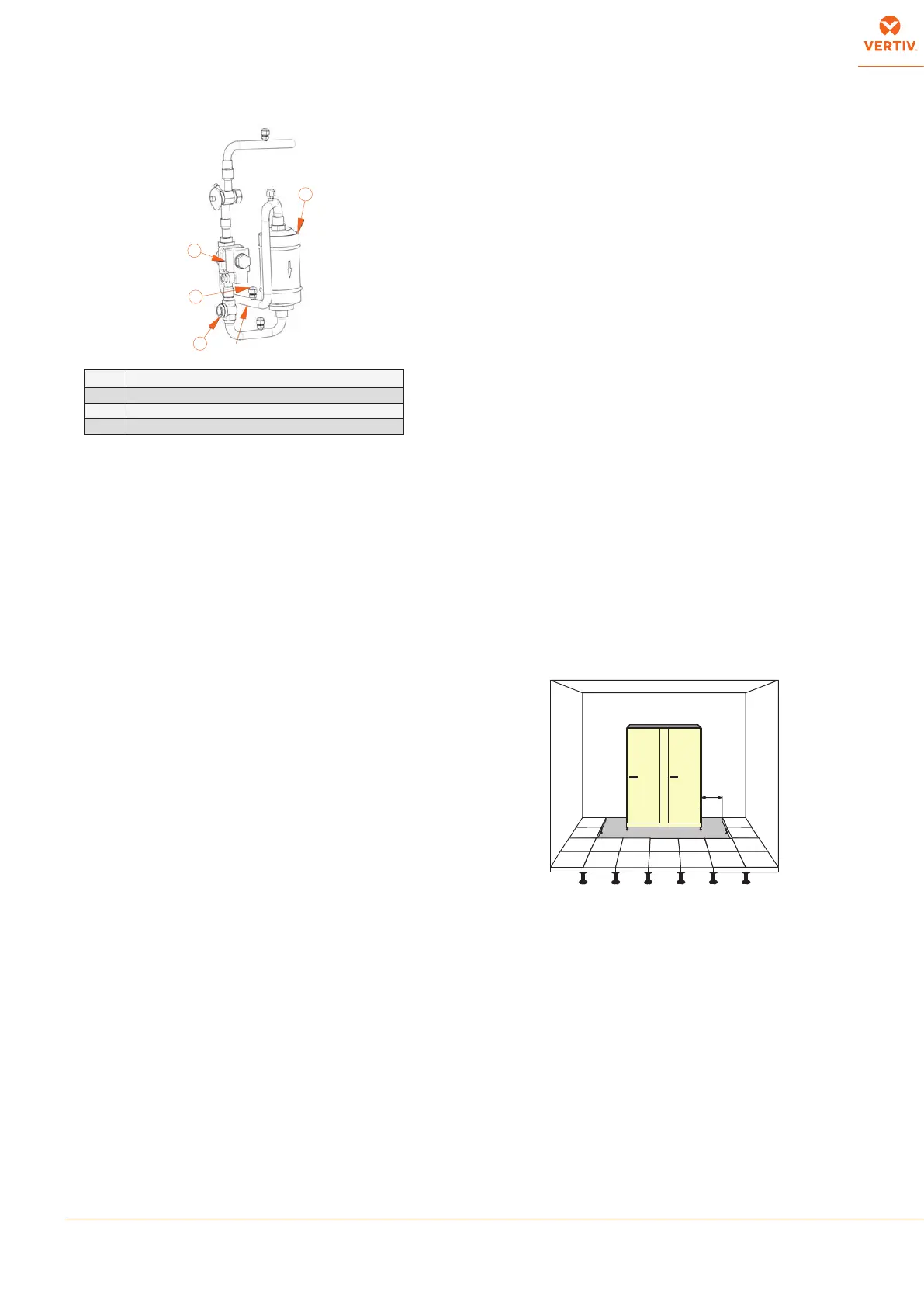

Fig. 14 - Refrigerant line components

8 - Operation

Unit operation is completely automatic. The below sequence

explains how the unit operates :

• The air, sucked in by the fan, enters the unit.

• The air is immediately ltered.

• The TEMPERATURE sensor or HUMITEMP (temperature +

rel. humidity) sensor (check type installed), veries the state of

the inlet air, and relays this information to the control system.

• Filtered new air is injected into the air stream via the Fresh Air

Intake (optional).

• The treated air passes through the fans, which operate

continuously, and is then dispersed out of the unit.

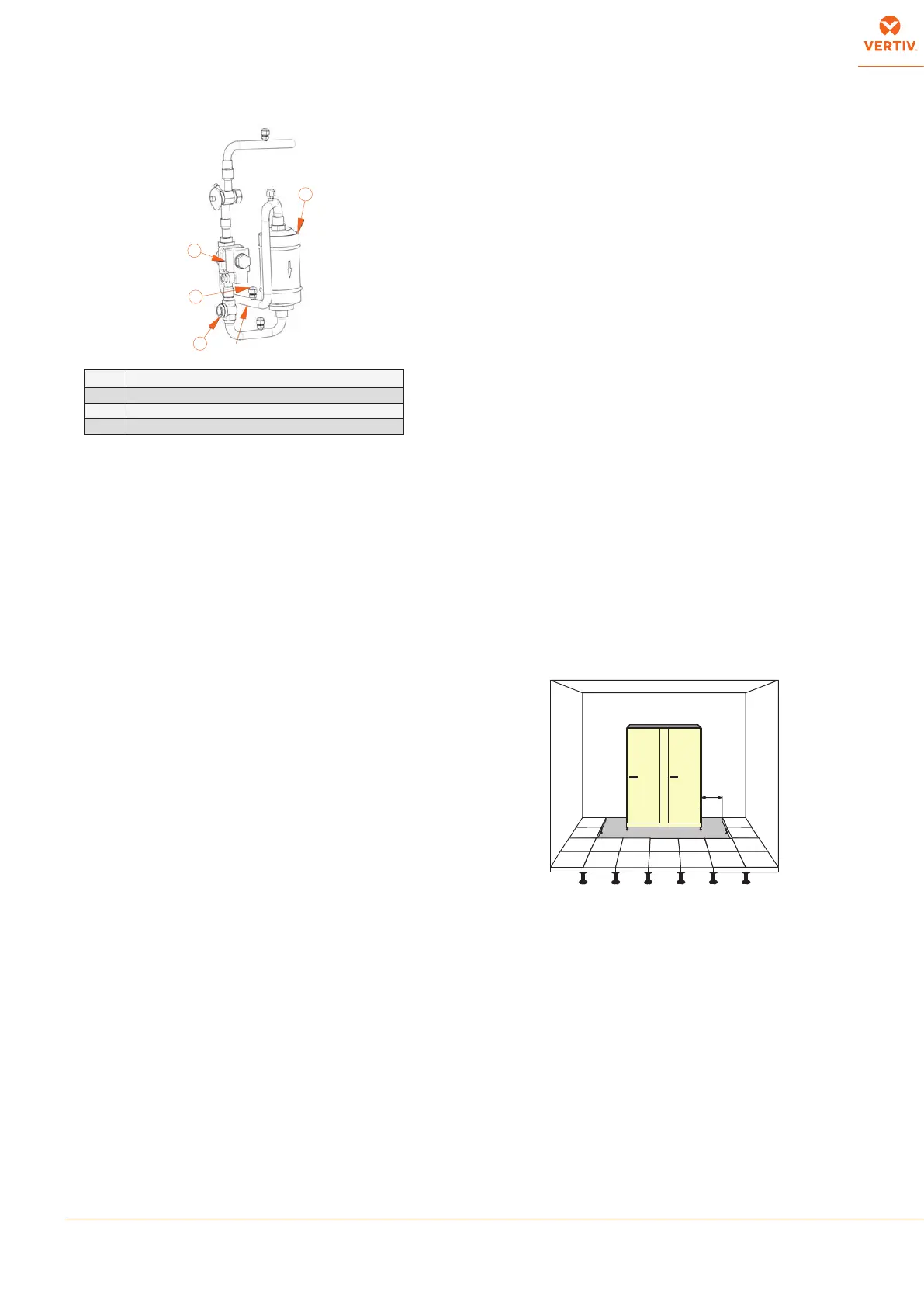

• The air passes from the underoor void into the room via

air distribution outlets. For “DOWNFLOW” units installed on

raised oor: switch o the machine before the oor panels

removal within a distance of 850mm from the machine, to

avoid risks of contact with rotating devices (fans) moving and

with hot heating elements. (see Fig. 15).

• The control system compares the relayed information to the

set point and proportional band values programmed into its

memory: it then commands the air conditioner to treat the air

as follows (see also Control manual):

• COOLING

The compressor (scroll compressor or digital scroll compressor,

with modulating capacity) is started and the cold refrigerant

ows through the evaporator, thus cooling the air passing over

it. For compressor operation see Control manual.

In dual circuit units, the evaporator is a dual stage coil, so the air

is cooled rst by one circuit (circuit n°1, compressor(s) on the

left side) and then by the other one (circuit n°2, compressor(s)

on the right side) . Temperature and pressure values related to

the two refrigerant circuits can be dierent.

• HEATING

This can take one of three forms:

• electrical heating (optional): the heating elements heat

the air passing over them. There is 1 heating step.

• Note: To protect the unit from superheating, one automatic

reset sensor set at 40°C and one or more manual reset

thermostats set at 120°C are installed.

• DUAL POWER SUPPLY - optional

This option allows a supply of electrical power from two

dierent electrical sources. It is possible to chose between

dierent solutions:

• Dual Power Supply Parallel: 2 separate power supplies:

during normal working mode both are present, during

emergency situation only the main one is present.

This means that during emergency mode full cooling

redundancy is granted disabling heating and humidifying.

This last option allows, during emergency mode, to

reduce unit power absorption and therefore Genset or

UPS sizes.

• Dual Power Supply Alternate Basic Version: 2 separate

power supplies: each power supply is able to completely

feed the unit. In case of failure of the main supply the unit

automatically switches to the second power supply. This

allows having a complete power supply redundancy or in

case needed to have during emergency mode full cooling

redundancy disabling heating and humidifying. This last

option allows during emergency mode to reduce unit

power absorption and therefore Genset or UPS sizes.

• DEHUMIDIFICATION - optional

DX mode

Compressor(s) starts and the air ow is reduced, thereby

causing dehumidication (refer also to Control manual).

Note: If, during dehumidication, the ambient temperature

drops below a specied level, dehumidication will be stopped

if necessary (see LOW LIMIT intervention in Control manual).

• HUMIDIFICATION - optional

The humidier creates steam, which is distributed into the air

stream via the steam distribution pipe (see also Enclosure A,

F, G).

Note: Manual control can be performed using the control system

(see Control manual).

Fig. 15 - Safe oor panels removal

9 - Calibrations & Regulation

(at start-up)

The air conditioner has already been factory tested and calibrated,

but it is very important to check, at start-up, the superheating.

See Tab. 5 and Tab. 6 (Enclosure B) that show all valves.

• The air conditioner has already been factory tested and

calibrated.

• For calibrations of instruments installed on the external

condensers/Dry coolers refer to the relevant manual.

• For control system calibrations refer to Control manual (to

prevent erratic operations do not use temperature sand rel.

humidity set points/proportional bands which dier excessively

from the Standard Settings).

1 Filter dryer inlet Schrader valve

2 Filter dryer

3 Sight glass

4 Solenoid valve (only with thermostatic expansion valve)

from Liquid

Receiver

4

1

2

3

850 mm

1 Filter dryer inlet Schrader valve

2 Filter dryer

3 Sight glass

4 Solenoid valve (only with thermostatic valve)

Loading...

Loading...