26

Liebert

®

PDX, EconoPhase Version - UM - 265133 - 29.08.2019

10.6 - Refrigeration circuit

WHEN REPAIRING THE REFRIGERATION CIRCUIT, COLLECT ALL REFRIGERANT IN A CONTAINER: DO NOT ALLOW IT TO

ESCAPE.

• When removing (for repairs) or charging refrigerant, it must always be done on both the high and low pressure sides of the compressor

simultaneously.

• The compressor copper plated steel connections should be welded with a silfos material containing a minimum of 5% silver.

10.6.2 - Oil charge R410A

The oil to be used when topping up (only if there are any leaks) is EMKARATE RL 32-3MA or Mobil EAL Arctic 22CC (see Tab. 9

and Tab. 10).

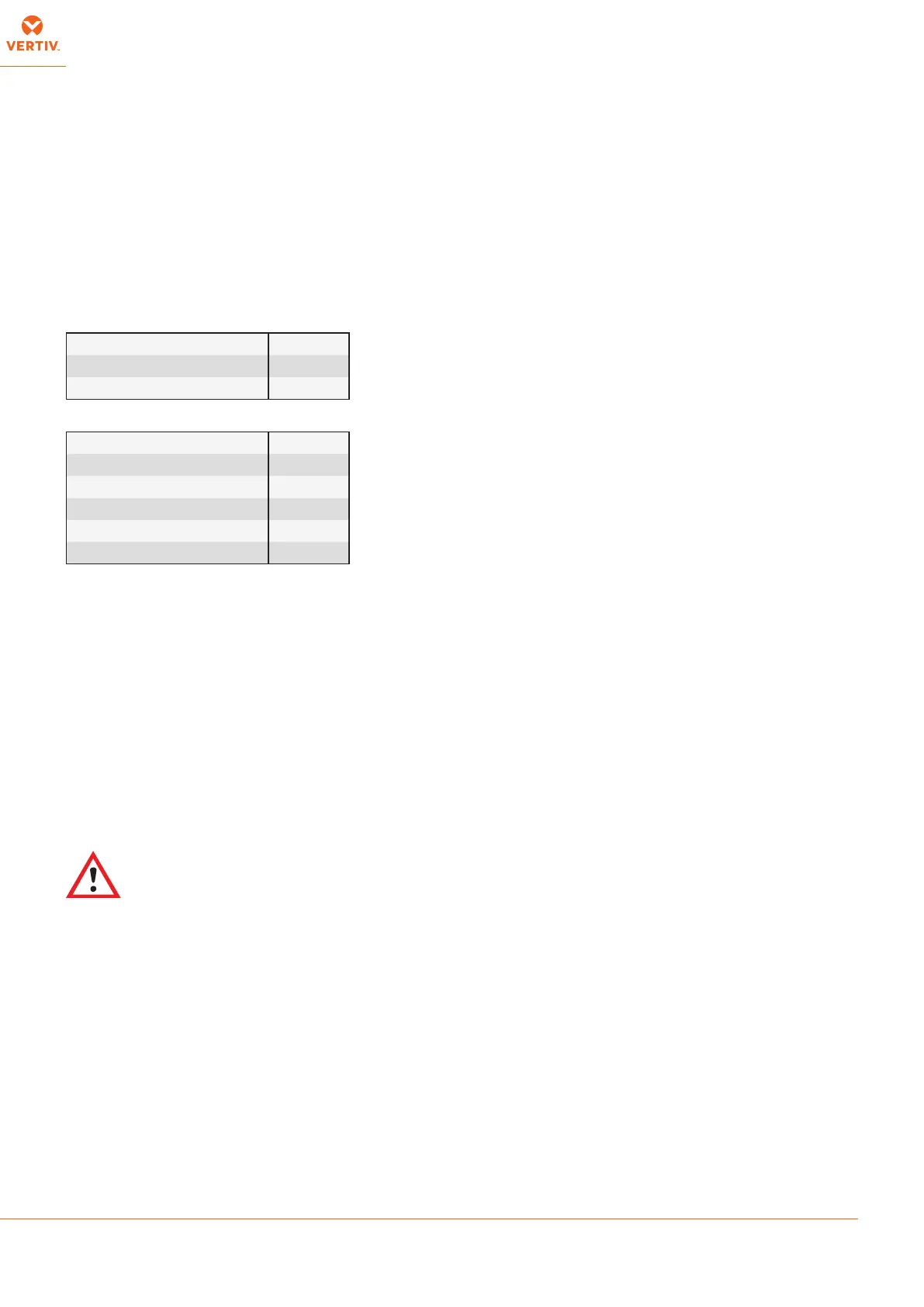

Tab. 9 - EMKARATE RL 32-3MA oil

Viscosity at 40

0

C : 31.2 cSt

Viscosity at 100

0

C : 5.6 cSt

Viscosity index (ISO Grade) : 32

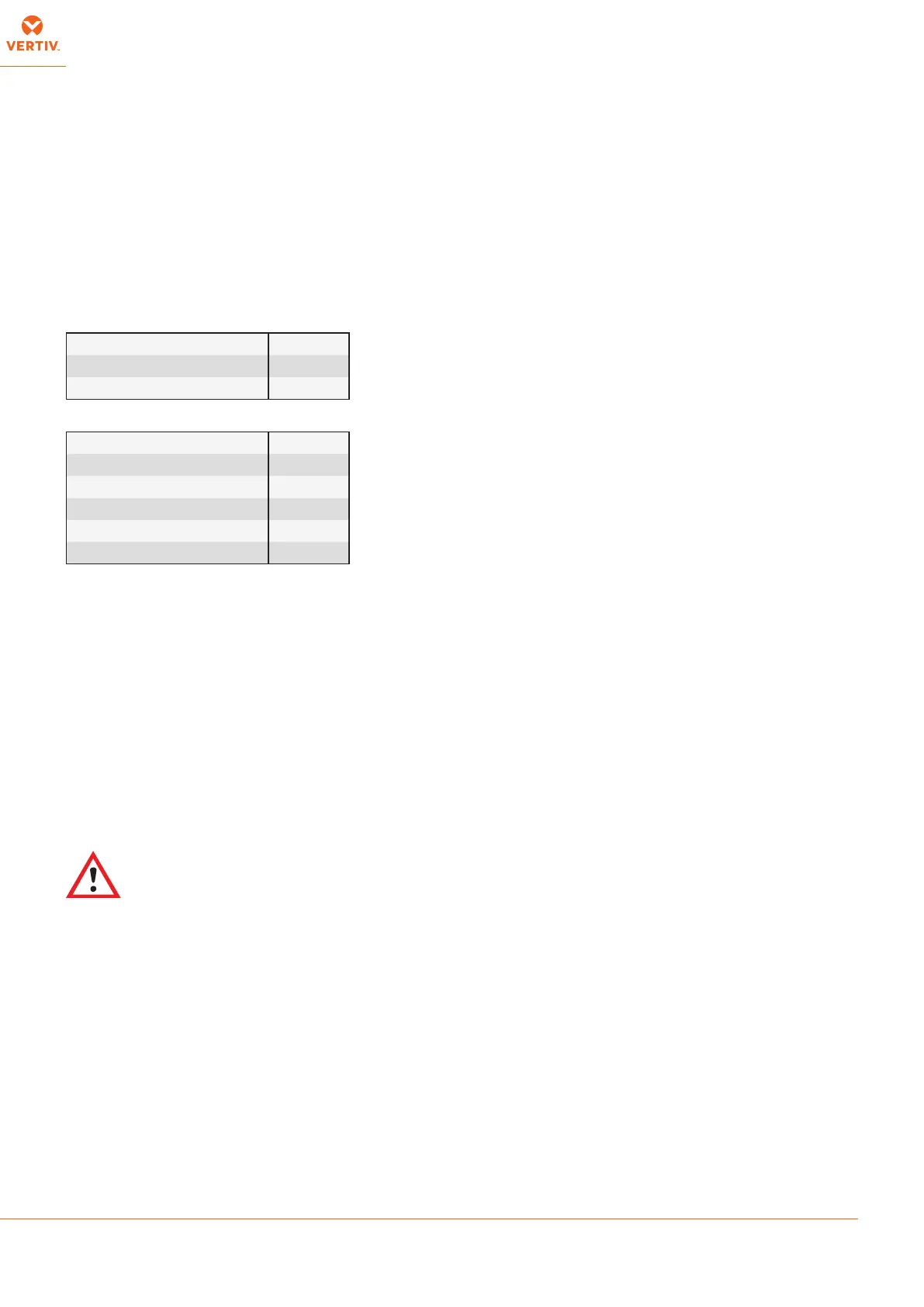

Tab. 10 - Mobil Arctic EAL 22CC oil

Density (at 15

0

C) : 0.967 kg/l

Flash point (C.O.C.) : 245 °C

Pour point : <-54 °C

Viscosity at 40

0

C : 23.6 cSt

Viscosity at 100

0

C : 4.7 cSt

Viscosity index (ASTM D2270) : 130

These oils rapidly absorb the humidity present in the air when they are exposed to the atmosphere.

If the oil absorbs humidity, the ester molecules can break down, forming acidity.

We therefore recommend exposing the oil for as short time as possible (no more than a few minutes) and, in case of topping up, using

exclusively the oil indicated on the refrigerating compressor.

Normally 1 or 2-litre cans are available for this purpose; once they are opened, they must be completely used up. They must not be used

after a long period, as they absorb humidity.

It is therefore obvious that the taps of the compressor must only be turned after the whole plant has been subjected to a vacuum and

partial lling.

10.6.3 - Oil topping-up of an installed circuit

If oil leakages occur, the topping-up operation is necessary.

(Contact the local Service before intervention).

10.7 - Dismantling the unit

The machine has been designed and built to ensure continuous operation.

The working life of some of the main components, such as the fan, depends on the maintenance that they receive.

CAUTION: The unit contains substances and components hazardous for the environment (electronic components, lead gel

battery, refrigerating gases and oils). At the end of the useful life, when the unit is dismantled, the operation must be carried

out by specialized refrigerating technicians. The unit must be delivered to suitable centers specialized for the collection and

disposal of equipment containing hazardous substances.

The lead gel battery, refrigeration uid and the lubricating oil inside the circuit must be recovered according to the laws in force

in the relevant country.

Loading...

Loading...