G0202MKD3 EN19

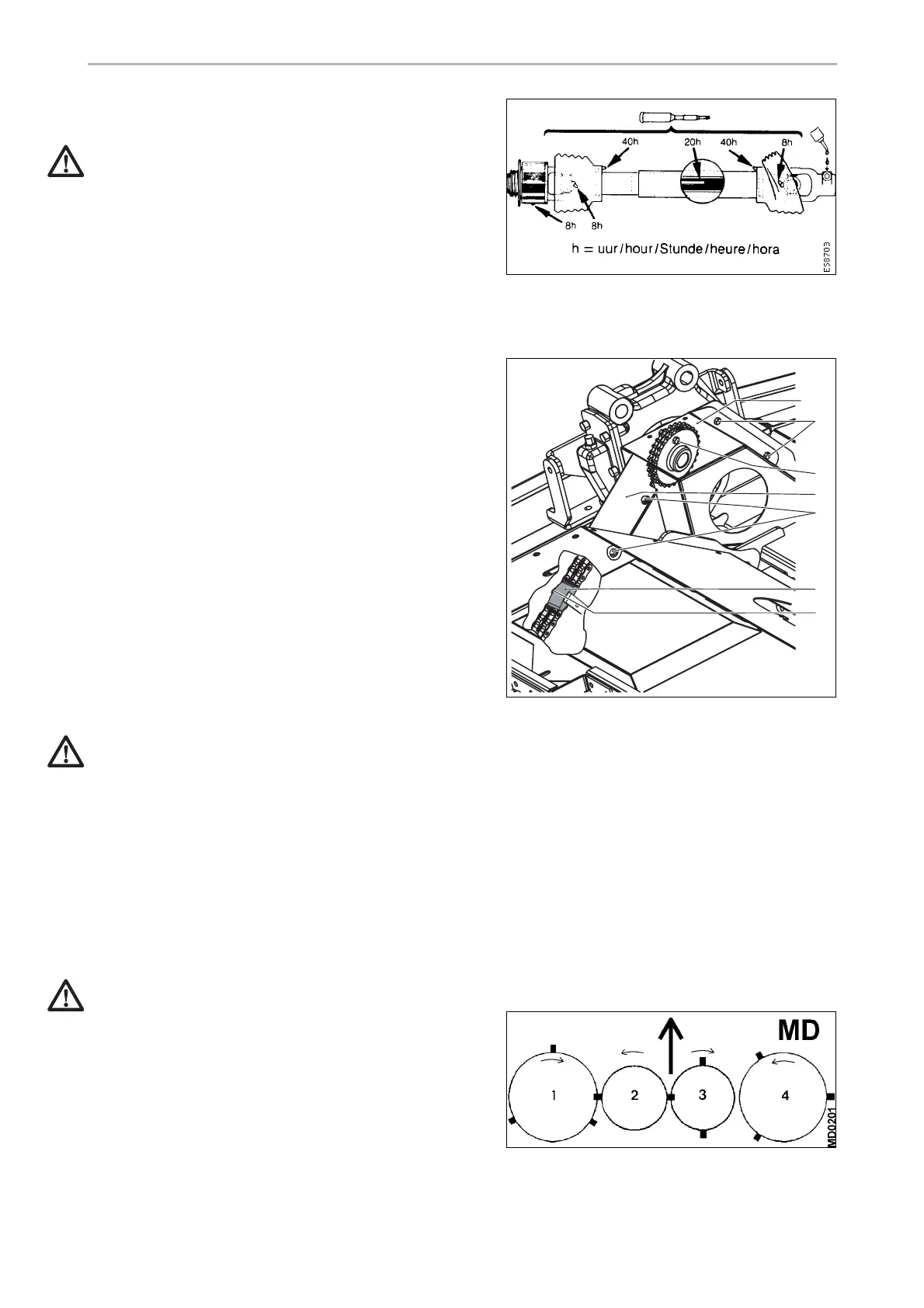

- Drive shaft between angle gear box and conditioner in

acc. with lower fig.

Attention:

Ensure profile tubes of pto drive shafts are well

greased at all times! Check a new or repaired ma-

chine and/or drive shaft prior to first run and then

every 20 working hours!

Also ensure sliding surfaces of the protection tubes

are greased!

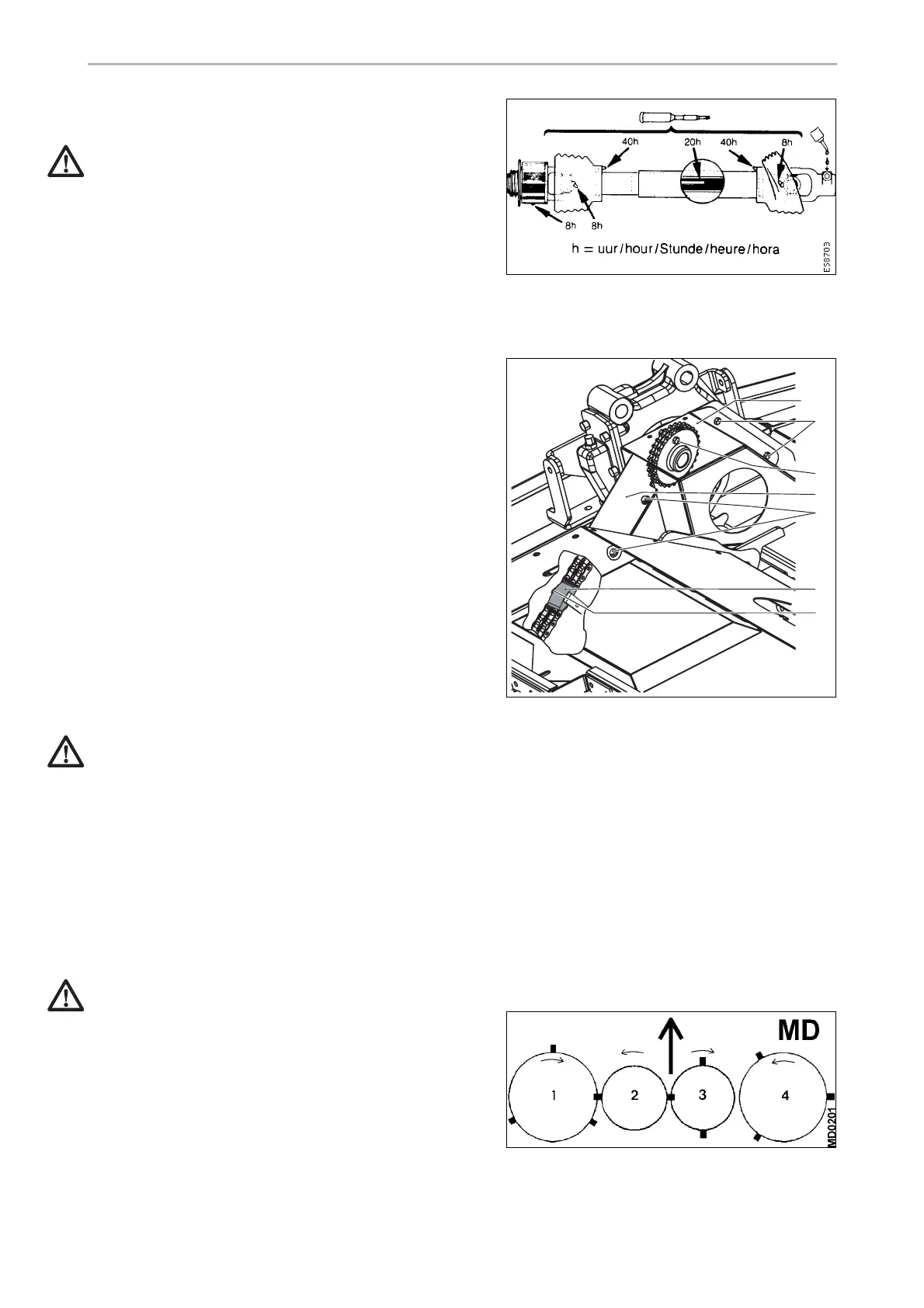

5.5 Tensioning and greasing the chains

The drive chain can be tensioned by means of the

nylon chain tensioners located under protective

hood (34). Check the chain tension regularly and if a

correction is required loosen the nylon chain tensioner

and push it by hand to a lower position.

1

Release the securing bolts and nuts (30). Pull out pro-

tective hood (34).

2

Check the chain tension: it will be correct if the chain

can still be flexed 1 cm (2,54”) at the underside.

3

Check the tension as follows: release the securing nut

(25) of the tensioner (26).

4

Push down the chain tensioner (26) by hand and hold

it fast in this position.

5

Tighten the securing nut (25).

6

Install the protective hood (34) and tighten the securing

bolts and nuts (30).

7

Oil the chains regularly (see 5.4).

5.6 Moving / renewing blade holders

Attention:

- Always exchange all blade holders per drum!

Ensure the blade holders of a drum skirt have the same

part number! This in order to avoid imbalance!

-

Renew damaged bolts/nuts as well as all

unscrewed lock nuts!

-

Tighten bolts/nuts in accordance with torque value

table of section 5.9!

After some time, wear of the drum skirts may become

apparent at the point where the blade holders are fitted.

Recheck regularly. If this wear is excessive the blade holders

of the drums can be transferred: proceed as follows:

Attention:

Always exchange all blade holders per drum!

Ensure the blade holders of a drum skirt have the

same part number!

This in order to avoid imbalance!

1

Rotate drums into basic position as shown in fig.

2

Remove skid saucer (see IPL).

3

Attach blade holders at new position.

4

Now move the blade holders of the other drum skirts in

order to produce the final situation shown in fig. (or 90°

rotated).

D0203

2

2

2

3

3

2

2

Loading...

Loading...