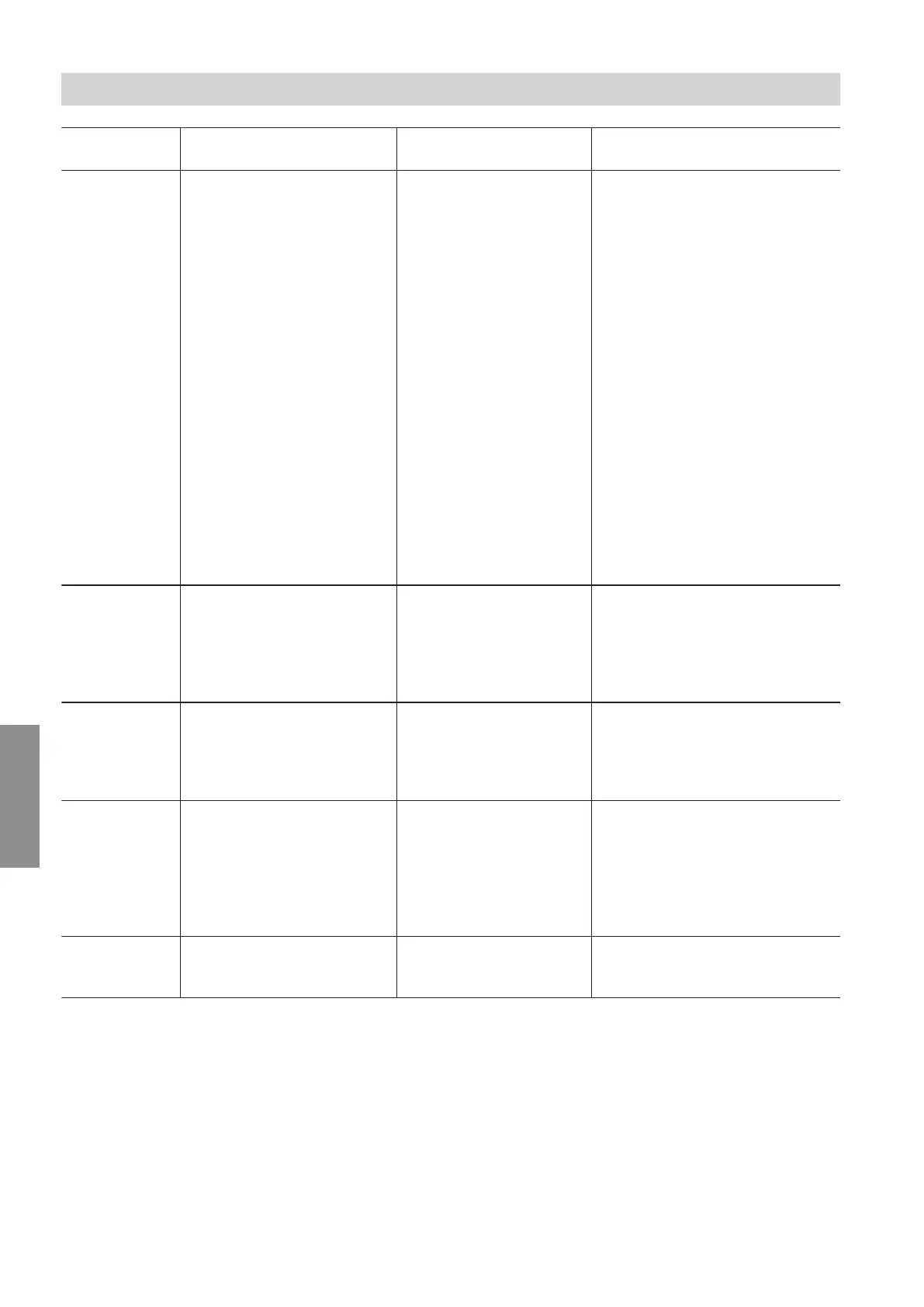

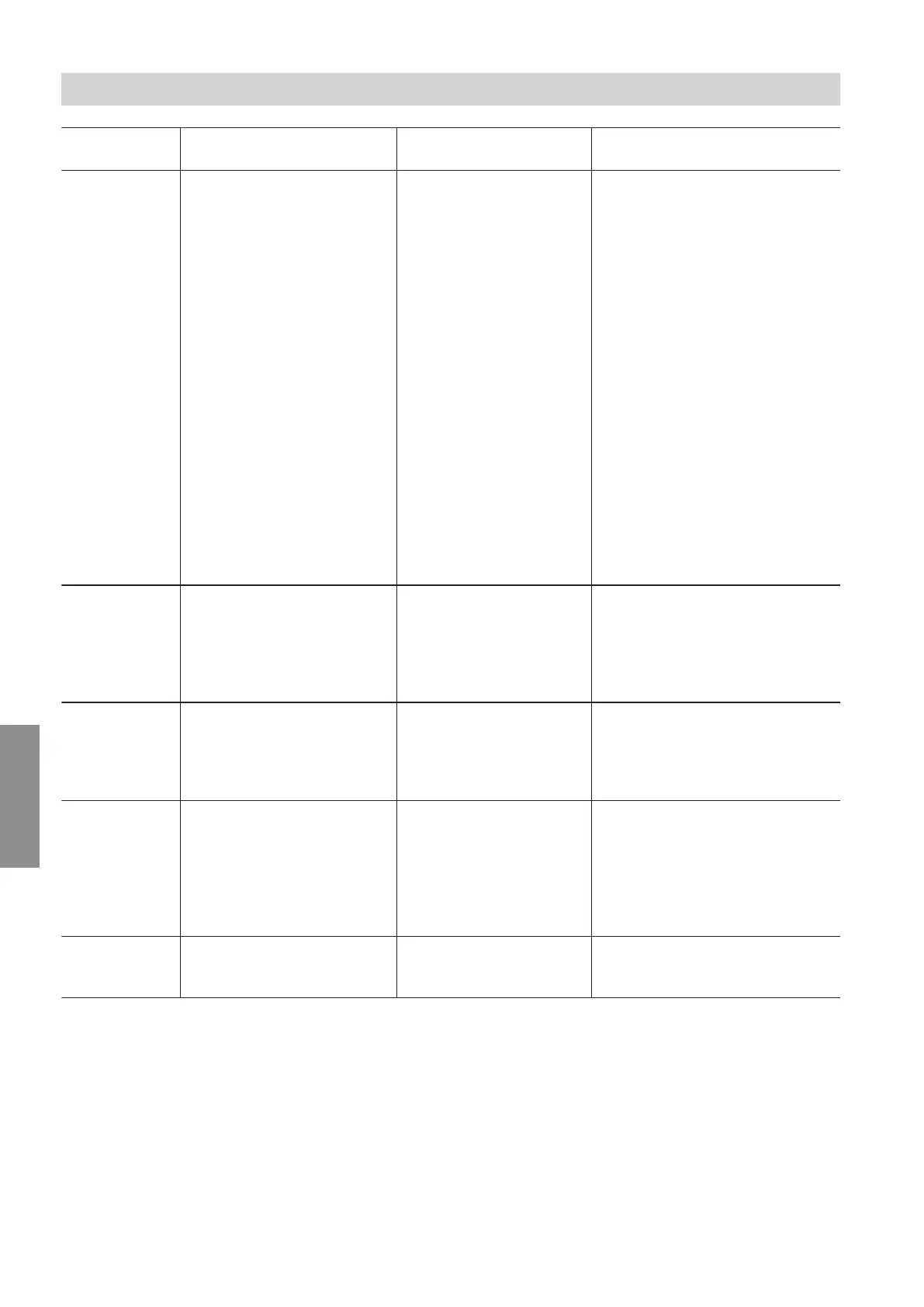

80

Displayed fault

code

System characteristics Cause Measures

468 Burner in a fault state Ionisation current too high

during calibration

Check gap between ionisation

electrode and burner gauze as-

sembly.

Check whether there is a lot of

dust in the ventilation air (e.g. from

construction work).

Reset the appliance.

Note

Deposits on the electrodes indicate

foreign bodies in the ventilation air.

Check the installation room and

flue system for causes of the de-

posits. For example: Laundry de-

tergents, cleaning agents, toilet-

ries, deposits in the ventilation air

supply (chimney).

If burner gauze assembly and ioni-

sation electrode have been re-

placed, also clean fan unit, gas/air

channel and Venturi extension.

471 No heat demand System pressure sensor

not available, lead break

or short circuit

■

Check system pressure sensor

(plug

aND

).

■

Check lead and plug-in connec-

tion.

■

Measure, to see if supply voltage

to sensor is 5 V–.

474 Burner in a fault state Error in scheduled pro-

gram run monitoring

Reset the appliance.

If the fault occurs repeatedly, re-

place the HBMU heat management

unit. See chapter "Replacing the

HBMU heat management unit".

517 Control mode, remote control

unit not functioning

Lead break, PlusBus ca-

ble, incorrect appliance

address set, remote con-

trol faulty

■

Check setting in the commission-

ing assistant and correct as nec-

essary.

■

Check remote control cable.

■

Check remote control subscriber

number. Replace faulty remote

control if applicable.

527, 528 Burner in a fault state Incorrect HBMU heat

management unit parame-

ter set

Overwrite (flash) the HBMU heat

management unit with the correct

parameter set.

Troubleshooting

Fault messages (cont.)

6167586

Diagnosis

Loading...

Loading...