21-6 Crank Mechanism

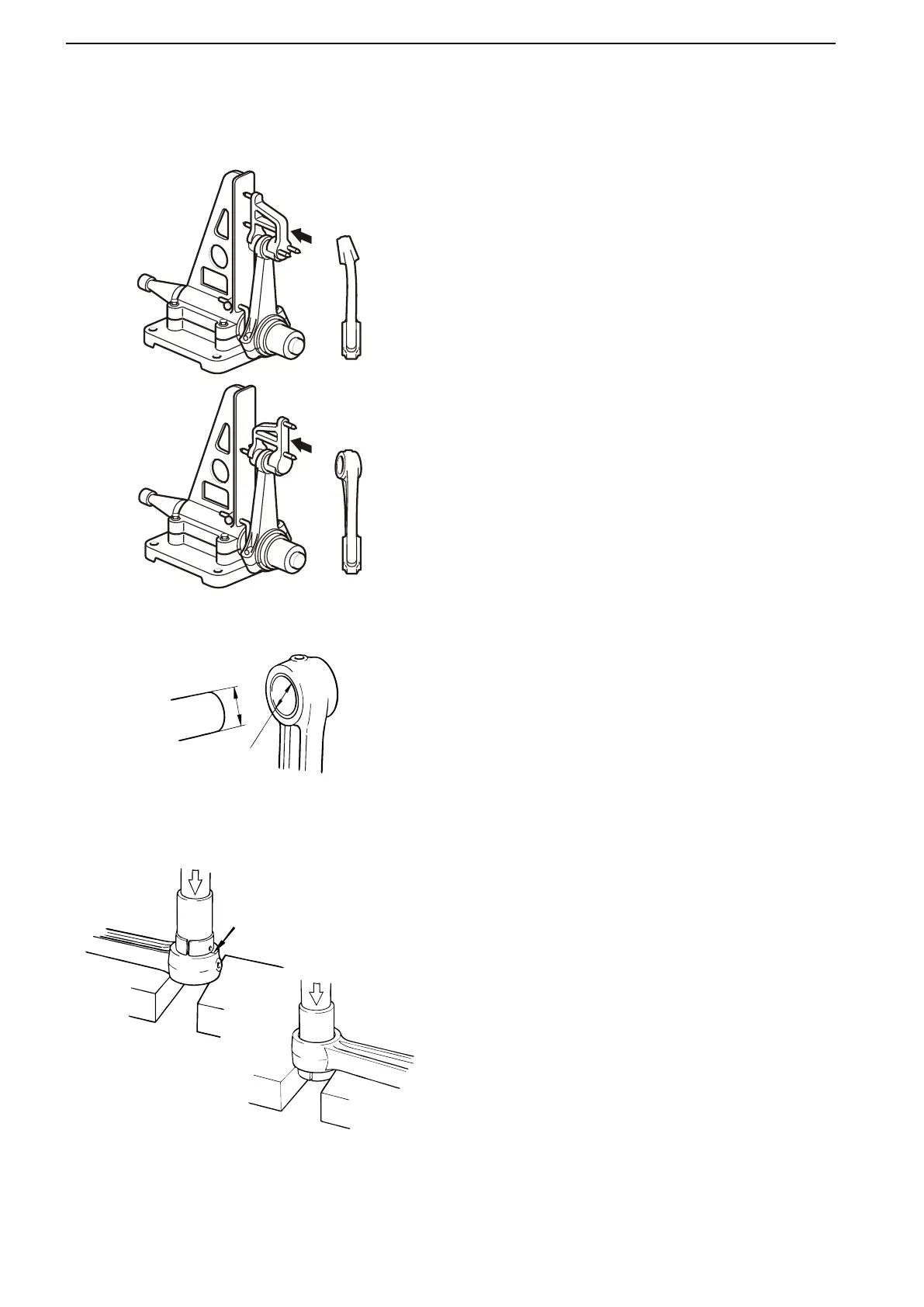

Con Rods, Inspection

1 Check the

connecting rods for cracking, straight-

ness and twist before any piston pin bush

replacement.

Scrap the connecting rod if it is cracked, bent or

twisted.

Check the wear in the "small end" with a piston pin.

When the clearance is correct, an oiled piston pin

should slowly slide through the bush under its own

weight.

2 Use a new piston pin and measure connecting

rod straightness

in a fixture. Max. deviation: 0.15

mm (0.0059") per 100 mm (3.9") measured

length.

3 Measure connecting rod twist. Max. deviation:

0.20 mm (0.0079") per 100 mm (3.9") measured

length.

4 Check the end float between the connecting rod

and crankshaft. Change the connecting rod if the

end float exceeds 0.035 - 0.085 mm (0.0014–

0.0033").

Also check the connecting rod bushes. For per-

missible clearance between the piston pin (A)

and the connecting rod bush (B), refer to Group

21: Engine page 14.

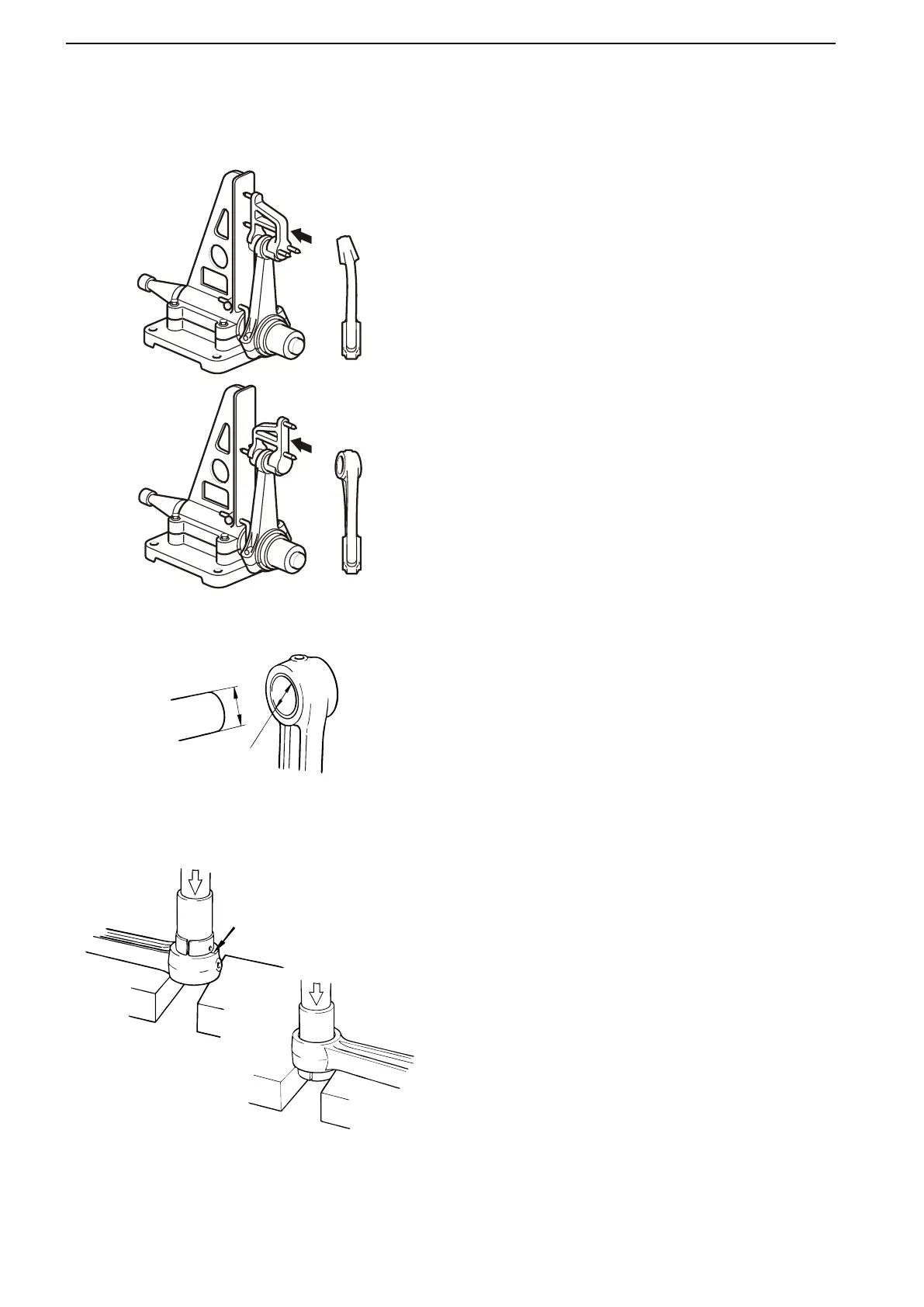

Changing the piston pin bushing

1 Press the old bush out.

2 Press the new bush in.

NOTICE! Make sure that the oil hole in the bush

lines up with the drilling in the connecting rod.

Using a felt tip pen, draw a line across the hole in

the connecting rod and the bush. Check that the

oil duct is open after pressing in the new bush.

3 Ream the bush and measure the connecting rod

with an internal dial gauge.

21-6 Crank Mechanism

88 47701798 05-2013 © AB VOLVO PENTA

Loading...

Loading...