74

Workshop notes

Workshop notes

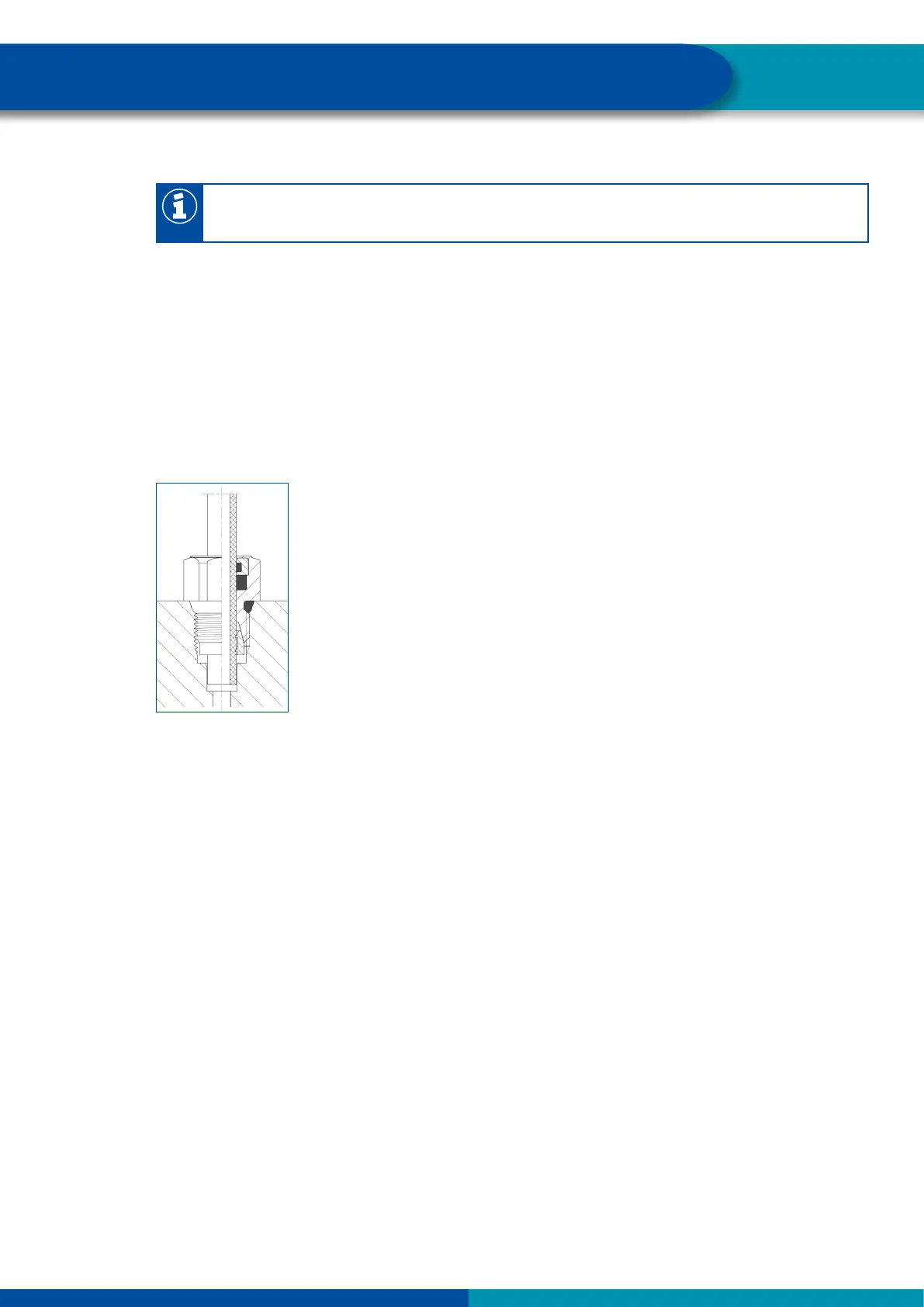

11.2.4 Replacing PA tubes (external sensor)

When removing the PA tube from the external sensor, take care that the thread on the external

sensor is kept clean.

Proceed as follows when replacing a defective PA tube:

1. Loosen the PA tube from the valve.

2. Unscrew the V203 connection together with the PA tube from the external sensor.

3. Check the thread on the external sensor for damage.

4. With damaged thread, replace the complete external sensor.

5. Screw the new V203 connection into the thread of the external sensor.

A new V203 connection can be obtained using the WABCO part number 893 770 005 2.

VOSS SV 203 connection

1. Tighten the V203 connection with a tightening torque of 3 Nm (hand tight).

2. Remove the protective cap of the V203 connection.

3. Insert the new, cut to length PA tube into the V203 connection.

4. Check if the PA tube has been pushed in until the stop into the V203 connection.

5. Check if the PA tube has a tight connection (approx. 20 N).

6. Connect the PA tube to the valve.

7. Tighten union nuts on the valve hand tight.

8. Check that the connection is tight using a leakage indicating spray.

11.2.5 Creeping pressure loss

If the WABCO Display indicates a creeping pressure loss:

– First use leak detection spray to check the connection of the indicated wheel between valve and

sensor.

– If these connections are tight, check bearing surface and edges.

So-called indicators at the tire edges point on damages at the carcass, which usually causes

creeping pressure loss of the wheel.

– If the casing is damaged, replace the tire.

Loading...

Loading...