5-28 BA DT08 SL EN – Edition 1.0 * * dt08b550.fm

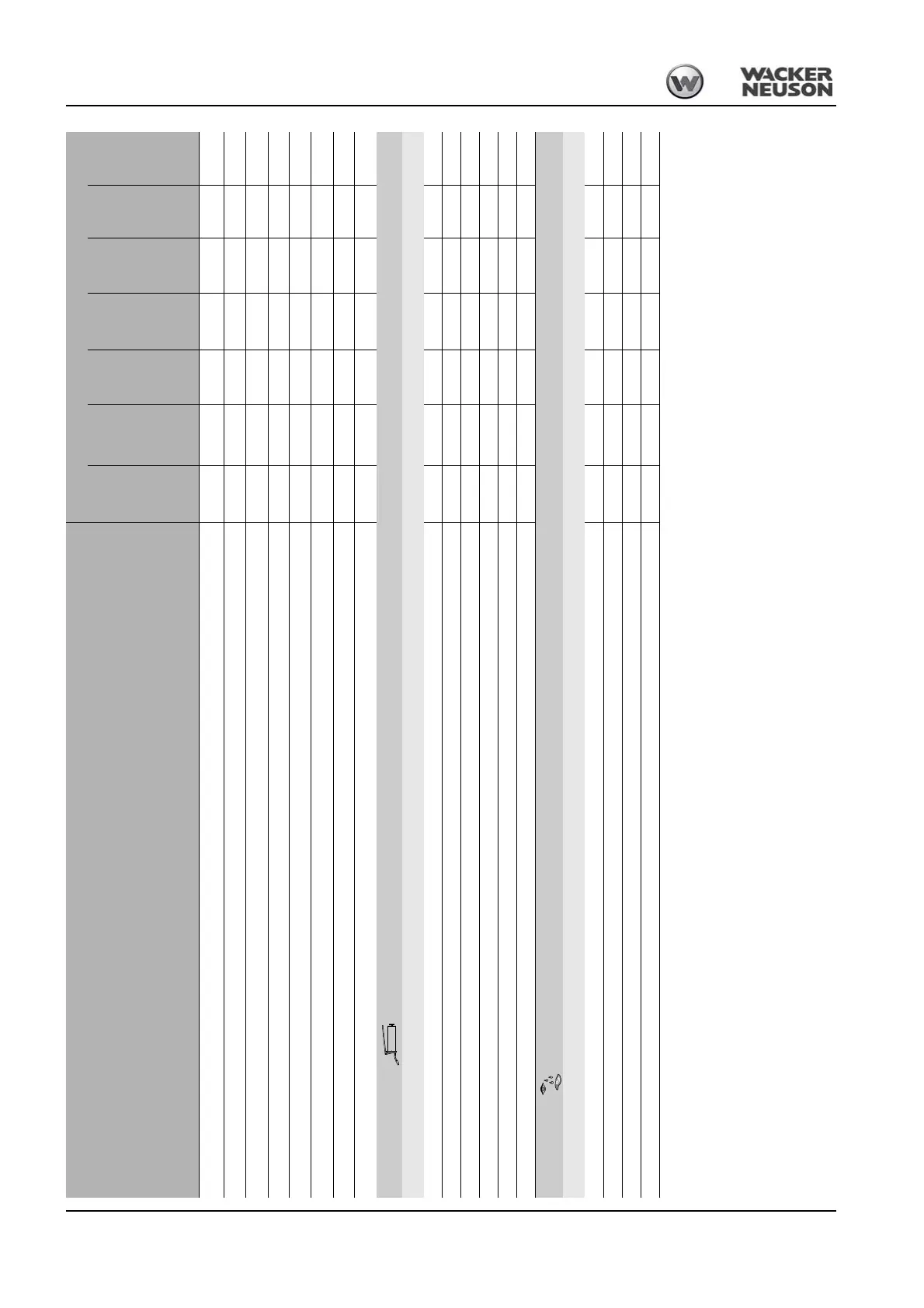

Maintenance

Check valve clearance. Adjust if necessary

●

●

Check track tension. Retighten if necessary

●●

Bearing play of tread rollers, track carrier rollers, front idlers

●●

Check piston rods for damage

●●

Check screws for tightness

●● ●

Pin lock

●●

Line fixtures

●●

Adhesive labels and Operator’s Manual

●● ●

Lubrication service ( ):

Lubricate the following assemblies/components – see Lubrication plan DT08 with skip on page 5-29:

•Skip ●●

• Tilt ram ●●

• Loader unit (option) ●●

• Loader unit rams (option) ●●

• Track tension ●●

• Track roller bearings ●●

Leakage check ( ):

Check for tightness, leaks and chafing: pipes, flexible lines and screw connections of the following assemblies and components. Rectify if necessary:

• Visual check

●●

☞ Engine and hydraulic system ●●

☞ Oil cooling circuit ●●

☞ Travelling drive ●●

1. Drain engine oil the first time after 50 s/h, then every 200 s/h

2. Replace the engine oil filter the first time after 50 s/h, then every 400 s/h

3. Replace the fuel filter the first time after 50 s/h, then every 400 s/h

4. Check and adjust injection time every other 1000 s/h servicing

5. Clean and adjust the fuel injection pump every other 1000 s/h servicing

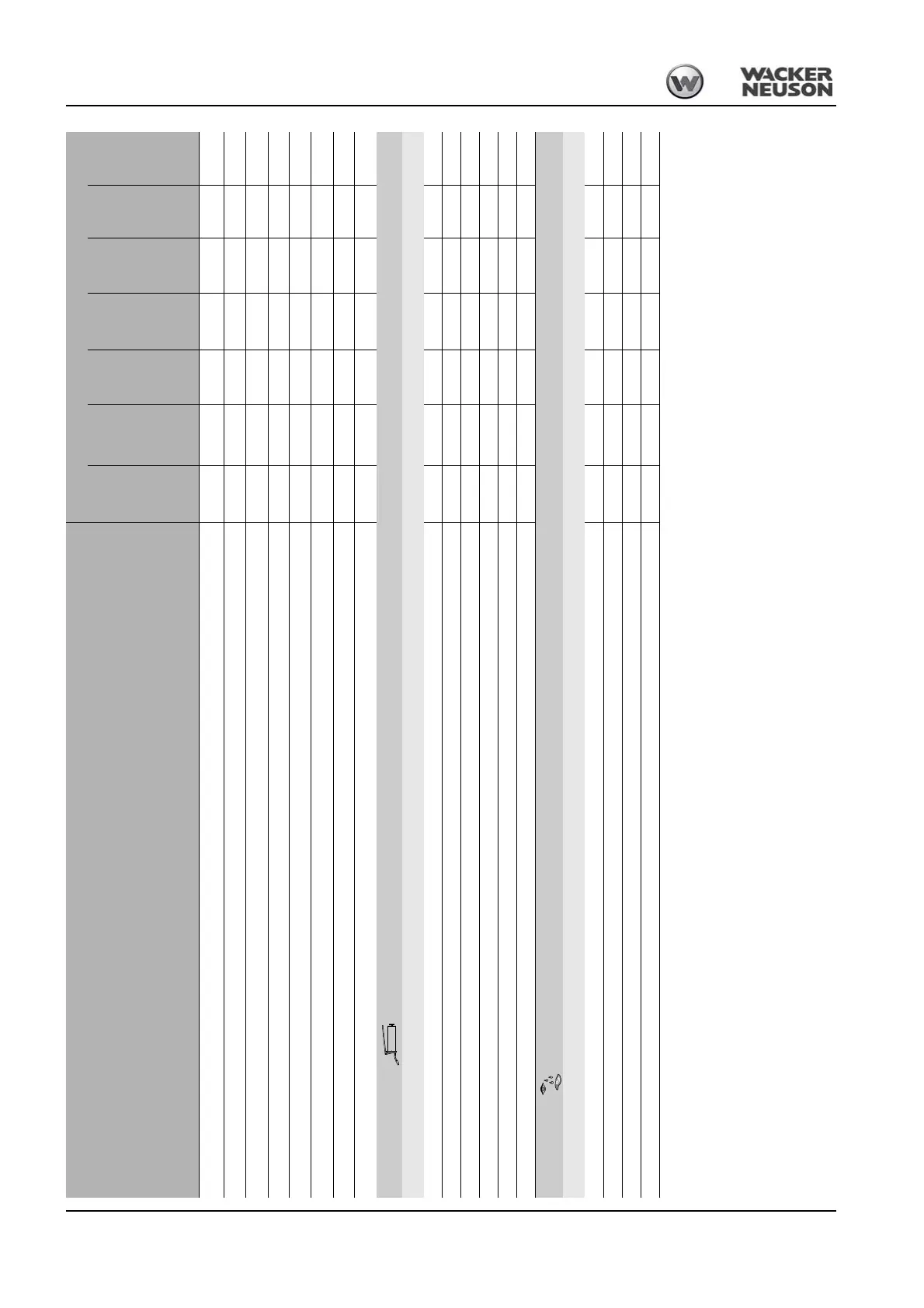

5.11 Maintenance plan DT08-D (diesel engine)

Work description

For service and maintenance work on the attachment, please refer to the operation and maintenance manual of the

attachment manufacturer as well.

Maintenance plan/service hours (s/h)

Service work

(daily)

Once a month or

after 50 s/h

Every 3 months or

after 200 s/h

Every 6 months

or after 400 s/h

Every 1000 s/h

once a year

Customer

Authorised

workshop

Loading...

Loading...