Operating manual Spray wall Basic 8000

8 Cleaning and Maintenance

30 Order number 3305595 | Edition 07/2022

8.2.5 Compressed Air Tank Maintenance

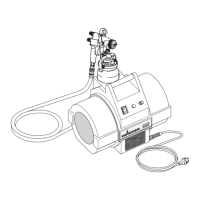

Rear side of the spray wall

1 Blow-off valve

Open to empty the compressed air tank

2 Compressed air supply to the pneumatic control cabinet

3 Compressed air tank for cleaning

The compressed air tank is normally maintenance-free.

To avoid malfunctions, regularly check the following points:

– Leaks in the supply lines or connection cables

– Leaks on the valve seat or saddle flange

– Fixed seat of the tank fixing

– If necessary, emptying of the condensate (blow-off valve 1)

Loading...

Loading...